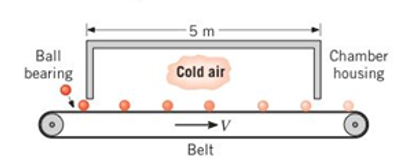

Problem 5.1P: Consider a thin electrical heater attached to a plate and backed by insulation. Initially, the... Problem 5.2P: The inner surface of a plane wall is insulated while the outer surface is exposed to an airstream at... Problem 5.3P: A microwave oven operates on the principle that application of a high-frequency field causes... Problem 5.4P: A plate of thickness 2L, surface area As, mass M, and specific heat cp, initially at a uniform... Problem 5.5P: For each of the following cases, determine an appropriate characteristic length Lc and the... Problem 5.6P: Steel balls 12 mm in diameter are annealed by heating to 1150K and then slowly cooling to 400 K in... Problem 5.7P: Consider the steel balls of Problem 5.6, except now the air temperature increases with time as... Problem 5.8P: The heat transfer coefficient for air flowing over a sphere is to be determined by observing the... Problem 5.9P: A solid steel sphere (AISI 1010), 300 mm in diameter, is coated with a dielectric material layer of... Problem 5.10P: A flaked cereal is of thickness 2L=1.2mm. The density, specific heat, and thermal conductivity of... Problem 5.11P: The base plate of an iron has a thickness of L=7mm and is made from an aluminum alloy... Problem 5.12P: Thermal energy storage systems commonly involve a packed bed of solid spheres, through which a hot... Problem 5.13P: A tool used for fabricating semiconductor devices consists of a chuck (thick metallic, cylindrical... Problem 5.14P: A copper sheet of thickness 2L=2mm has an initial temperature of Ti=118C. It is suddenly quenched in... Problem 5.15P: Carbon steel (AISI 1010) shafts of 0.1-m diameter are heat treated in a gas-fired furnace whose... Problem 5.16P: A thermal energy storage unit consists of a large rectangular channel. which is well insulated on... Problem 5.17P: Small spherical particles of diameter D=50m contain a fluorescent material that. when irradiated... Problem 5.18P: A spherical vessel used as a reactor for producing pharmaceuticals has a 5-mm-thick stainless steel... Problem 5.19P: Batch processes are often used in chemical and pharmaceutical operations to achieve a desired... Problem 5.20P: An electronic device. such as a power transistor mounted on a finned heat sink. can be modeled as a... Problem 5.21P: Molecular electronics is an emerging field associated with computing and data storage utilizing... Problem 5.22P: A plane wall of a furnace is fabricated from plain carbon steel (k=60W/mK,=7850kg/m3,c=430J/kgK) and... Problem 5.23P: A steel strip of thickness =12mm is annealed by passing it through a large furnace whose walls are... Problem 5.24P: In a material processing experiment conducted aboard the space shuttle. a coated niobium sphere of... Problem 5.25P: Plasma spray-coating processes are often used to provide surface protection for materials exposed to... Problem 5.26P: The plasma spray-coating process of Problem 5.25 can be used to produce nanostructured ceramic... Problem 5.27P: A chip that is of length L=5mm on a side and thickness t=1mm is encased in a ceramic substrate, and... Problem 5.28P: Consider the conditions of Problem 5.27. In addition to treating heat transfer by convection... Problem 5.29P: A long wire of diameter D=1mm is submerged in an oil bath of temperature T=25C. The wire has an... Problem 5.30P: Consider the system of Problem 5.1 where the temperature of the plate is spacewise isothermal during... Problem 5.31P: Shape memory alloys (SMAs) are metals that undergo a change in crystalline structure within a... Problem 5.32P: Before being injected into a furnace, pulverized coal is preheated by passing it through a... Problem 5.33P: As noted in Problem 5.3, microwave ovens operate by rapidly aligning and reversing water molecules... Problem 5.34P: A metal sphere of diameter D, which is at a uniform temperature Ti, is suddenly removed from a... Problem 5.35P: A horizontal structure consists of an LA=10 mm-thick layer of copper and an LB=10 -mm-thick layer of... Problem 5.36P: As permanent space stations increase in size. there is an attendant increase in the amount of... Problem 5.37P: Thin film coatings characterized by high resistance to abrasion and fracture may be formed by using... Problem 5.38P: A long. highly polished aluminum rod of diameter D=35mm is hung horizontally in a large room. The... Problem 5.39P: Thermal stress testing is a common procedure used to assess the reliability of an electronic... Problem 5.40P: The objective of this problem is to develop thermal models for estimating the steady-state... Problem 5.41P: In thermomechanical data storage, a processing head, consisting of M heated cantilevers. is used to... Problem 5.42P: The melting of water initially at the fusion temperature, Tf=0C, was considered in Example... Problem 5.43P: Consider the series solution, Equation 5.42, for the plane wall with convection. Calculate midplane... Problem 5.44P: Consider the one-dimensional wall shown in the sketch, which is initially at a uniform temperature... Problem 5.45P: Copper-coated, epoxy-tilled fiberglass circuit boards are treated by heating a stack of them under... Problem 5.46P: Circuit boards are treated by heating a stack of them under high pressure, as illustrated in Problem... Problem 5.47P: A constant-property, one-dimensional plane slab of width 2L initially at a uniform temperature. is... Problem 5.48P: Referring to the semiconductor processing tool of Problem 5.13. it is desired at some point in the... Problem 5.49P: Annealing is a process by which steel is reheated and then cooled to make it less brittle. Consider... Problem 5.50P: Consider an acrylic sheet of thickness L=5mm that is used to coat a hot. isothermal metal substrate... Problem 5.51P: The 150-mm-thick wall of a gas-fired furnace is constructed of fireclay brick... Problem 5.52P: Steel is sequentially heated and cooled (annealed) to relieve stresses and to make it less brittle.... Problem 5.53P: Stone mix concrete slabs are used to absorb thermal energy from flowing air that is carried from a... Problem 5.55P: During transient operation, the steel nozzle of a rocket engine must not exceed a maximum allowable... Problem 5.56P: Two plates of the same material and thickness L are at different initial temperatures Ti,1 and Ti,2... Problem 5.57P: In a tempering process, glass plate, which is initially at a uniform temperature Ti is cooled by... Problem 5.58P: The strength and stability of tires may be enhanced by heating both sides of the rubber... Problem 5.59P: A plastic coating is applied to wood panels by first depositing molten polymer on a panel and then... Problem 5.60P: A long rod of 60-mm diameter and thermophysical properties =8000kg/m3,c=500J/kgK, and k=50W/mK is... Problem 5.61P: A long cylinder of 30-mm diameter, initially at a uniform temperature of 1000 K, is suddenly... Problem 5.63P: A long pyroceram rod of diameter 20 mm is clad with a very thin metallic tube for... Problem 5.64P: A long rod 40 mm in diameter, fabricated from sapphire (aluminum oxide) and initially at a uniform... Problem 5.65P: A cylindrical stone mix concrete beam of diameter D=0.5m initially at Ti=20C is exposed to hot gases... Problem 5.66P: A long plastic rod of 30-mm diameter (k=0.3W/mKandcp=1040kJ/m3K) is uniformly heated in an oven as... Problem 5.67P: As part of a heat treatment process, cylindrical, 304 stainless steel rods of 100-mm diameter are... Problem 5.68P: In a manufacturing process, long rods of different diameters are at a uniform temperature 400C of in... Problem 5.69P: The density and specific heat of a particular material are known (=1200kg/m3,cp=1250J/kgK), but its... Problem 5.71P: In heat treating to harden steel ball bearings (c=500J/kgK,=7800kg/m3,k=50W/mK), it is desirable to... Problem 5.72P: A cold air chamber is proposed for quenching steel ball bearings of diameter D=0.2m and initial... Problem 5.74P: Stainless steel (AISI 304) ball bearings. which have uniformly been heatedto 850C, are hardened by... Problem 5.75P: A sphere 30 mm in diameter initially at 800K is quenched in a large bath having a constant... Problem 5.77P: Spheres A and B are initially at 800K. and they are simultaneously quenched in large constant... Problem 5.78P: Spheres of 40-mm diameter heated to a uniform temperature of 400C are suddenly removed from the oven... Problem 5.79P: To determine which parts of a spider's brain are triggered into neural activity in response to... Problem 5.80P: Consider the packed bed operating conditions of Problem 5.12, but with Pyrex... Problem 5.83P: Two large blocks of different materials. such as copper and concrete, have been sitting in a room... Problem 5.84P: A plane wall of thickness 0.6 m (L=0.3m) is made of steel (k=30W/mK,=7900kg/m3,c=640J/kgK). It is... Problem 5.85P: Asphalt pavement may achieve temperatures as high as 50°C on a hot summer day. Assume that such a... Problem 5.86P: A thick steel slab (=7800kg/m3,c=480J/kgK,k=50W/mK) is initially at 300C and is cooled by water jets... Problem 5.87P: A tile-iron consists of a massive plate maintained at 150C by an embedded electrical heater. The... Problem 5.88P: A simple procedure for measuring surface convection heat transfer coefficients involves coating the... Problem 5.89P: An insurance company has hired you as a consultant to improve their understanding of burn injuries.... Problem 5.90P: A procedure for determining the thermal conductivity of a solid material involves embedding a... Problem 5.91P: A very thick slab with thermal diffusivity 5.6106m2/s and thermal conductivity 20W/mK is initially... Problem 5.93P: Standards for firewalls may be based on their thermal response to a prescribed radiant heat flux.... Problem 5.94P: It is well known that, although two materials are at the same temperature, one may feel cooler to... Problem 5.95P: Two stainless steel plates (=8000Kg/m3,c=500J/kgK,k=15W/mK), each 20mm thick and insulated on one... Problem 5.96P: Special coatings are often formed by depositing thin layers of a molten material on a solid... Problem 5.97P: When a molten metal is cast in a mold that is a poor conductor, the dominant resistance to heat flow... Problem 5.98P: Joints of high quality can be formed by friction welding. Consider the friction welding of two... Problem 5.99P: A rewritable optical disc (DVD) is formed by sandwiching a 15-nm-thick binary compound storage... Problem 5.100P: Ground source heat pumps operate by using the soil, rather than ambient air, as the heat source (or... Problem 5.101P: To enable cooking a wider range of foods in microwave ovens, thin, metallic packaging materials have... Problem 5.102P: Derive an expression for the ratio of the total energy transferred from the isothermal surface of an... Problem 5.103P: The structural components of modem aircraft are commonly fabricated of high-performance composite... Problem 5.104P: Consider the plane wall of thickness 2L, the infinite cylinder of radius ro, and the sphere of... Problem 5.105P: Problem 4.9 addressed radioactive wastes stored under-ground in a spherical container. Because of... Problem 5.106P: Derive an expression for the ratio of the total energy transferred from the isothermal surface of a... Problem 5.107P Problem 5.108P Problem 5.109P: A thin rod of diameter D is initially in equilibrium with its surroundings, a large vacuum enclosure... Problem 5.110P: A one-dimensional slab of thickness 2L is initially at a uniform temperature Ti. Suddenly, electric... Problem 5.114P Problem 5.115P Problem 5.117P: A molded plastic product (=1200kg/m3,c=1500J/kgK,k=0.30W/mK) is cooled by exposing one surface to an... Problem 5.133P Problem 5.137P: A thin circular disk is subjected to induction heating from a coil, the effect of which is to... Problem 5.139P: Two very long (in the direction normal to the page) bars having the prescribed initial temperature... Problem 5S.2P Problem 5S.3P Problem 5S.4P: Estimate the time required to cook a hot dog in boiling water. Assume that the hot dog is initially... Problem 5S.7P Problem 5S.9P Problem 5S.10P Problem 5S.11P Problem 5S.13P format_list_bulleted

Principles of Heat Transfer (Activate Learning wi...Mechanical EngineeringISBN:9781305387102Author:Kreith, Frank; Manglik, Raj M.Publisher:Cengage Learning

Principles of Heat Transfer (Activate Learning wi...Mechanical EngineeringISBN:9781305387102Author:Kreith, Frank; Manglik, Raj M.Publisher:Cengage Learning