Concept explainers

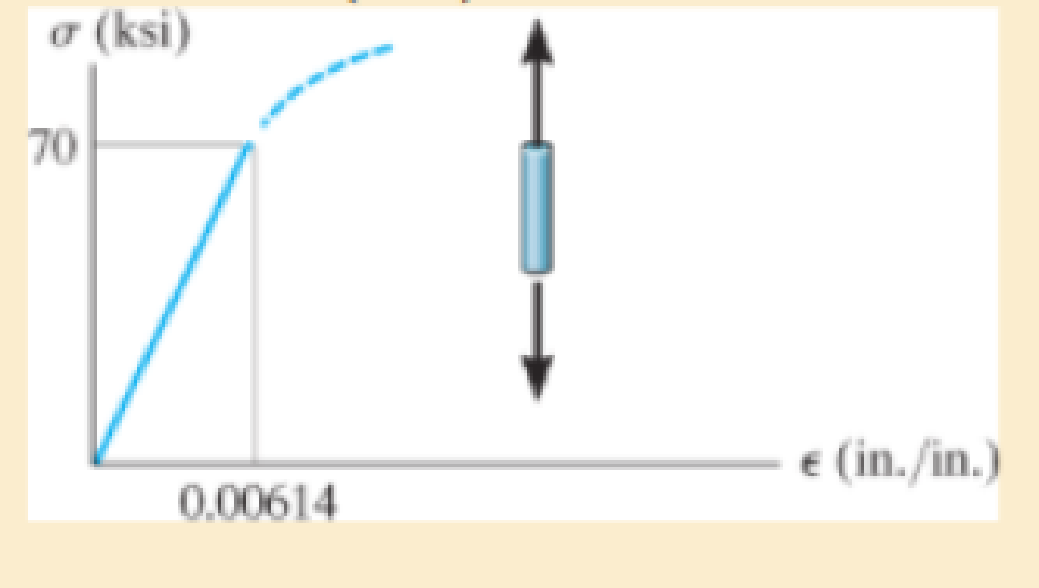

The elastic portion of the tension stress-strain diagram for an aluminum alloy is shown in the figure. The specimen used for the test has a gage length of 2 in. and a diameter of 0.5 in. When the applied load is 9 kip, the new diameter of the specimen is 0.49935 in. Calculate the shear modulus Gal for the aluminum.

The shear modulus for an aluminum alloy

Answer to Problem 3.1RP

The shear modulus for an aluminum alloy is

Explanation of Solution

Given information:

Gage length is

The diameter of the specimen is

The axial load acts on the specimen is

The new diameter of the specimen is

Calculation:

Calculate the modulus of elasticity for aluminum

Here, the stress is

Refer the stress-strain diagram.

The value of stress is 70 ksi and the value of strain is

Substitute 70 ksi for

The expression to find the cross-sectional area of the specimen

Here, the diameter of the specimen is

Substitute

Find the value of stress when the specimen is loaded with a 9 kip load using the relation:

Here, the load is P.

Substitute 9 kip for P and

The expression to find the strain in the longitudinal or axial direction

Here, the Young’s modulus of the aluminum is

Substitute

Find the strain in lateral direction

Here, the new diameter is

Substitute

Find the Poisson’s ratio

Substitute

Calculate the modulus of rigidity for the specimen

Substitute

Therefore, the shear modulus for an aluminum alloy is

Want to see more full solutions like this?

Chapter 3 Solutions

Mechanics of Materials (10th Edition)

Additional Engineering Textbook Solutions

Starting Out with Programming Logic and Design (5th Edition) (What's New in Computer Science)

Degarmo's Materials And Processes In Manufacturing

Database Concepts (8th Edition)

Java How to Program, Early Objects (11th Edition) (Deitel: How to Program)

Thinking Like an Engineer: An Active Learning Approach (4th Edition)

Computer Science: An Overview (13th Edition) (What's New in Computer Science)

- PROBLEM 3.46 The solid cylindrical rod BC of length L = 600 mm is attached to the rigid lever AB of length a = 380 mm and to the support at C. When a 500 N force P is applied at A, design specifications require that the displacement of A not exceed 25 mm when a 500 N force P is applied at A For the material indicated determine the required diameter of the rod. Aluminium: Tall = 65 MPa, G = 27 GPa. Aarrow_forwardFind the equivalent mass of the rocker arm assembly with respect to the x coordinate. k₁ mi m2 k₁arrow_forward2. Figure below shows a U-tube manometer open at both ends and containing a column of liquid mercury of length l and specific weight y. Considering a small displacement x of the manometer meniscus from its equilibrium position (or datum), determine the equivalent spring constant associated with the restoring force. Datum Area, Aarrow_forward

- 1. The consequences of a head-on collision of two automobiles can be studied by considering the impact of the automobile on a barrier, as shown in figure below. Construct a mathematical model (i.e., draw the diagram) by considering the masses of the automobile body, engine, transmission, and suspension and the elasticity of the bumpers, radiator, sheet metal body, driveline, and engine mounts.arrow_forward3.) 15.40 – Collar B moves up at constant velocity vB = 1.5 m/s. Rod AB has length = 1.2 m. The incline is at angle = 25°. Compute an expression for the angular velocity of rod AB, ė and the velocity of end A of the rod (✓✓) as a function of v₂,1,0,0. Then compute numerical answers for ȧ & y_ with 0 = 50°.arrow_forward2.) 15.12 The assembly shown consists of the straight rod ABC which passes through and is welded to the grectangular plate DEFH. The assembly rotates about the axis AC with a constant angular velocity of 9 rad/s. Knowing that the motion when viewed from C is counterclockwise, determine the velocity and acceleration of corner F.arrow_forward

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning