Gaston Company manufactures furniture. One of its product lines is an economy-line kitchen table. During the last year, Gaston produced and sold 100,000 units for $100 per unit. Sales of the table are on a bid basis, but Gaston has always been able to win sufficient bids using the $100 price. This year, however, Gaston was losing more than its share of bids. Concerned, Larry Franklin, owner and president of the company, called a meeting of his executive committee (Megan Johnson, marketing manager; Fred Davis, quality manager; Kevin Jones, production manager; and Helen Jackson, controller).

LARRY: I don’t understand why we’re losing bids. Megan, do you have an explanation?

MEGAN: Yes, as a matter of fact. Two competitors have lowered their price to $92 per unit. That’s too big a difference for most of our buyers to ignore. If we want to keep selling our 100,000 units per year, we will need to lower our price to $92. Otherwise, our sales will drop to about 20,000 to 25,000 per year.

HELEN: The unit contribution margin on the table is $10. Lowering the price to $92 will cost us $8 per unit. Based on a sales volume of 100,000, we’d make $200,000 in contribution margin. If we keep the price at $100, our contribution margin would be $200,000 to $250,000. If we have to lose, let’s just take the lower market share. It’s better than lowering our prices.

MEGAN: Perhaps. But the same thing could happen to some of our other product lines. My sources tell me that these two companies are on the tail end of a major quality improvement program—one that allows them significant savings. We need to rethink our whole competitive strategy—at least if we want to stay in business. Ideally, we should match the price reduction and work to reduce the costs to recapture the lost contribution margin.

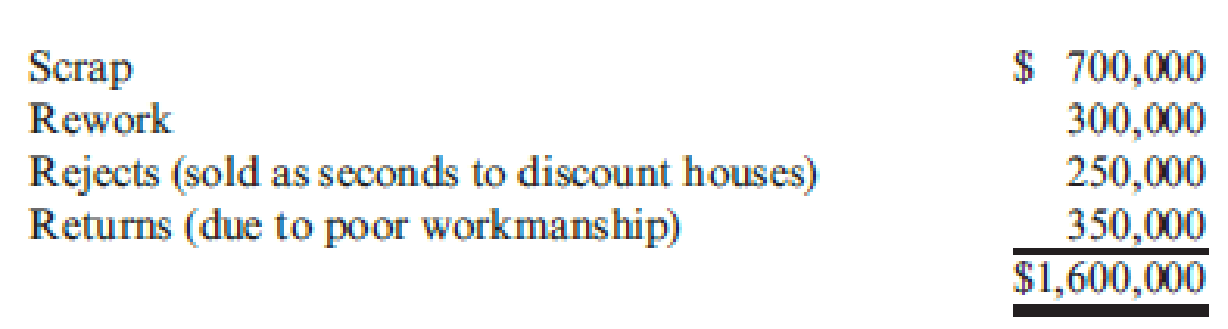

FRED: I think I have something to offer. We are about to embark on a new quality improvement program of our own. I have brought the following estimates of the current quality costs for this economy line. As you can see, these costs run about 16 percent of current sales. That’s excessive, and we believe that they can be reduced to about 4 percent of sales over time.

LARRY: This sounds good. Fred, how long will it take for you to achieve this reduction?

FRED: All these costs vary with sales level, so I’ll express their reduction rate in those terms. Our best guess is that we can reduce these costs by about 1 percent of sales per quarter. So it should take about 12 quarters, or three years, to achieve the full benefit. Keep in mind that this is with an improvement in quality.

MEGAN: This offers us some hope. If we meet the price immediately, we can maintain our market share. Furthermore, if we can ever reach the point of reducing the price below the $92 level, then we can increase our market share. I estimate that we can increase sales by about 10,000 units for every $1 of price reduction beyond the $92 level. Kevin, how much extra capacity for this line do we have?

KEVIN: We can handle an extra 30,000 or 40,000 tables per year.

Required:

- 1. Assume that Gaston immediately reduces the bid price to $92. How long will it be before the unit contribution margin is restored to $10, assuming that quality costs are reduced as expected and that sales are maintained at 100,000 units per year (25,000 per quarter)?

- 2. Assume that Gaston holds the price at $92 until the 4 percent target is achieved. At this new level of quality costs, should the price be reduced? If so, by how much should the price be reduced, and what is the increase in contribution margin? Assume that price can be reduced only in $1 increments.

- 3. Assume that Gaston immediately reduces the price to $92 and begins the quality improvement program. Now, suppose that Gaston does not wait until the end of the three-year period before reducing prices. Instead, prices will be reduced when profitable to do so. Assume that prices can be reduced only by $1 increments. Identify when the first future price change should occur (if any).

- 4. Discuss the differences in viewpoints concerning the decision to decrease prices and the short-run contribution margin analysis done by Helen, the controller. Did quality cost information play an important role in the strategic decision making illustrated by the problem?

Trending nowThis is a popular solution!

Chapter 14 Solutions

Cornerstones of Cost Management (Cornerstones Series)

- The monthly cost of a data plan for mercury communications?arrow_forwardFalcon enterprise reported the following financial dataarrow_forwardIf a business has revenue of $677,000, cost of goods sold of $214,000, operating expenses of $157,000, and pays $70,000 in taxes, what is the net income? General Accountarrow_forward

- Please give answer this financial accounting questionarrow_forwardSamuel Stevens' monthly pay stub indicates that his monthly gross income is $4,200. However, $900 is withheld for income and Social Security taxes, $250 is withheld for his health and disability insurance, and another $250 is contributed to his pension plan. How much is Samuel's disposable income? Need answerarrow_forwardSamuel Stevens' monthly pay stub indicates that his monthly gross income is $4,200. However, $900 is withheld for income and Social Security taxes, $250 is withheld for his health and disability insurance, and another $250 is contributed to his pension plan. How much is Samuel's disposable income?arrow_forward

- If a business has revenue of $677,000, cost of goods sold of $214,000, operating expenses of $157,000, and pays $70,000 in taxes, what is the net income?arrow_forwardFinancial Accounting Questionarrow_forwardSamuel Stevens' monthly pay stub indicates that his monthly gross income is $4,200. However, $900 is withheld for income and Social Security taxes, $250 is withheld for his health and disability insurance, and another $250 is contributed to his pension plan. How much is Samuel's disposable income? provide answerarrow_forward

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning