Concept explainers

For the problem specified in the table, build upon the results of the original problem to determine the minimum factor of safety for yielding. Use both the maximum-shear-stress theory and the distortion-energy theory, and compare the results. The material is 1018 CD steel.

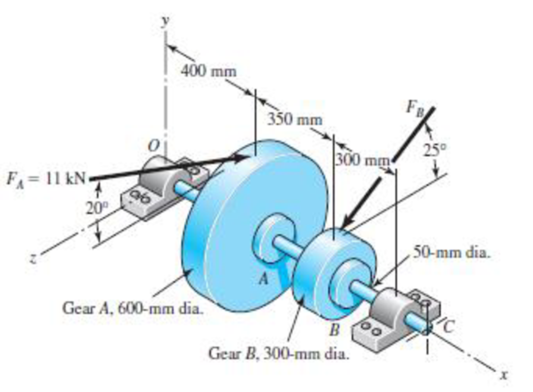

3–72* to 3–73* A gear reduction unit uses the countershaft shown in the figure. Gear A receives power from another gear with the transmitted force FA applied at the 20° pressure angle as shown. The power is transmitted through the shaft and delivered through gear B through a transmitted force FB at the pressure angle shown.

(a) Determine the force FB, assuming the shaft is running at a constant speed.

(b) Find the bearing reaction forces, assuming the bearings act as simple supports.

(c) Draw shear-force and bending-moment diagrams for the shaft. If needed, make one set for the horizontal plane and another set for the vertical plane.

(d) At the point of maximum bending moment, determine the bending stress and the torsional shear stress.

(e) At the point of maximum bending moment, determine the principal stresses and the maximum shear stress.

The factor of safety for yielding from maximum-shear-stress theory.

The factor of safety for yielding from distortion-energy theory.

Answer to Problem 44P

The factor of safety for yielding from maximum-shear-stress theory is

The factor of safety for yielding from distortion-energy theory is

Explanation of Solution

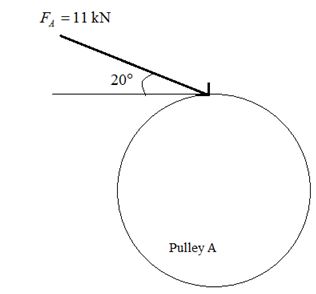

The figure below shows the free body diagram of pulley A.

Figure-(1)

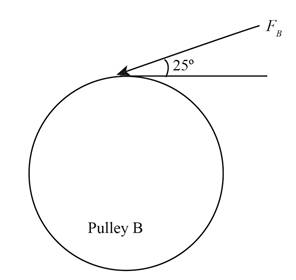

The figure below shows the free body diagram of pulley B.

Figure-(2)

Calculate the force

Here, the force acting on pulley

Write the moment about bearing

Here, the reaction force at bearing

Write the equation to balance the forces in

Here, the reaction force at bearing

Write the moment about bearing

Here, the reaction force at bearing

Write the equation to balance the forces in

Here, the reaction force at bearing

Calculate the reaction forces at bearing

Here, the reaction force at bearing

Calculate the reaction forces at bearing

Here, the reaction force at bearing

The calculations for shear force and bending moment diagram in

Calculate the shear force at

Here, the shear force at

Calculate the shear force at

Here, the shear force at

Calculate the shear force at

Here, the shear force at

Calculate the shear force at

Here, the shear force at

Calculate the moment at

Here, the moment at

Calculate the moment at

Here, the moment at

Calculate the moment at

Here, the moment at

The calculations for shear force and bending moment diagram in

Calculate the shear force at

Here, the shear force at

Calculate the shear force at

Here, the shear force at

Calculate the shear force at

Here, the shear force at

Calculate the shear force at

Here, the shear force at

Calculate the moment at

Here, the moment at

Calculate the moment at

Here, the moment at

Calculate the moment at

Here, the moment at

Write the net moment at

Here, the net moment at

Write the net moment at

Here, the net moment at

Write the torque transmitted by shaft from

Here, the torque transmitted by shaft from

Calculate the bending stress.

Here, the bending stress is

Calculate the shear stress.

Here, the shear stress is

Calculate the maximum principal stress.

Here, the maximum principal stress is

Calculate the minimum principal stress.

Here, the minimum principal stress is

Calculate the maximum shear stress.

Here, maximum shear stress is

Calculate the factor of safety from maximum-shear-stress theory.

Here, the maximum yield stress for

Calculate the factor of safety from distortion-energy theory.

Here, the Von Mises stress is

Write the expression for von Mises stress.

Substitute

Conclusion:

Convert the forces into

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Since,

The critical location is at

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Refer to the Table A-20 “Deterministic ASTM Minimum Tensile and Yield Strengths for Some Hot-Rolled (HR) and Cold-Drawn (CD) Steels” and obtain

Substitute

Thus, the factor of safety for yielding from maximum-shear-stress theory is

Substitute

Thus, the factor of safety for yielding from distortion-energy theory is

Want to see more full solutions like this?

Chapter 5 Solutions

Shigley's Mechanical Engineering Design (McGraw-Hill Series in Mechanical Engineering)

- Determine the minimum applied force P required to move wedge A to the right. The spring is compressed a distance of 175 mm. Neglect the weight of A and B. The coefficient of static friction for all contacting surface is μs = 0.35. Neglect friction at the rollers. k = = 15 kN/m P A B 10°arrow_forwardDO NOT COPY SOLUTION- will report The differential equation of a cruise control system is provided by the following equation: Find the closed loop transfer function with respect to the reference velocity (vr) . a. Find the poles of the closed loop transfer function for different values of K. How does the poles move as you change K? b. Find the step response for different values of K and plot in MATLAB. What can you observe?arrow_forwarda box shaped barge 37m long, 6.4 m beam, floats at an even keel draught of 2.5 m in water density 1.025 kg/m3. If a mass is added and the vessel moves into water density 1000 kg/m3, determine the magnitude of this mass if the fore end and aft end draughts are 2.4m and 3.8m respectively.arrow_forward

- a ship 125m long and 17.5m beam floats in seawater of 1.025 t/m3 at a draught of 8m. the waterplane coefficient is 0.83, block coefficient 0.759 and midship section area coefficient 0.98. calculate i) prismatic coefficient ii) TPC iii) change in mean draught if the vessel moves into water of 1.016 t/m3arrow_forwardc. For the given transfer function, find tp, ts, tr, Mp . Plot the resulting step response. G(s) = 40/(s^2 + 4s + 40) handplot only, and solve for eacharrow_forwardA ship of 9000 tonne displacement floats in fresh water of 1.000 t/m3 at a draught 50 mm below the sea water line. The waterplane area is 1650 m2. Calculate the mass of cargo which must be added so that when entering seawater of 1.025 t/m3 it floats at the seawater line.arrow_forward

- A ship of 15000 tonne displacement floats at a draught of 7 metres in water of 1.000t/cub. Metre.It is required to load the maximum amount of oil to give the ship a draught of 7.0 metre in seawater ofdensity 1.025 t/cub.metre. If the waterplane area is 2150 square metre, calculate the massof oil requiredarrow_forwardA ship of 8000 tonne displacement floats in seawater of 1.025 t/m3 and has a TPC of 14. The vessel moves into fresh water of 1.000 t/m3 and loads 300 tonne of oil fuel. Calculate the change in mean draught.arrow_forwardAuto Controls DONT COPY ANSWERS - will report Perform the partial fraction expansion of the following transfer function and find the impulse response: G(s) = (s/2 + 5/3) / (s^2 + 4s + 6) G(s) =( 6s^2 + 50) / (s+3)(s^2 +4)arrow_forward

- I submitted the below question and received the answer i copied into this question as well. Im unsure if it is correct, so looking for a checkover. i am stuck on the part tan-1 (0.05) = 0.04996 radians. Just unsure where the value for the radians came from. Just need to know how they got that answer and how it is correct before moving on to the next part. If any of the below information is wrong, please feel free to give me a new answer or an entire new explanation. An Inclining experiment done on a ship thats 6500 t, a mass of 30t was moved 6.0 m transvesly causing a 30 cm deflection in a 6m pendulum, calculate the transverse meta centre height. Here is the step-by-step explanation: Given: Displacement of the ship (W) = 6500 tonnes = 6500×1000=6,500,000kg Mass moved transversely (w) = 30 tonnes=30×1000=30,000kg The transverse shift of mass (d) = 6.0 meters Pendulum length (L) = 6.0 meters Pendulum deflection (x) = 30 cm = 0.30 meters Step 1: Formula for Metacentric Height…arrow_forwardAnswer the assignment question, expert onlyarrow_forwardA 1 inch rod diameter B 3/4 inch rod diameter C 1/2 inch rod diameter D 3/8 inch rod diameterarrow_forward

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning