Materials for Civil and Construction Engineers (4th Edition)

4th Edition

ISBN: 9780134320533

Author: Michael S. Mamlouk, John P. Zaniewski

Publisher: PEARSON

expand_more

expand_more

format_list_bulleted

Textbook Question

Chapter 6, Problem 6.40QP

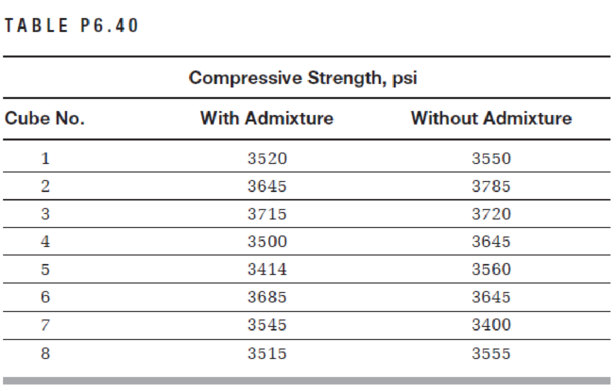

A materials engineer is working in a research project to evaluate the effect of one type of admixture on the compressive strength of concrete. He tested eight mortar cubes made with admixture and eight others without admixture after 28 days of curing. The compressive strengths of cubes in psi with and without admixture are shown in Table P6.40.

Using the statistical t-test, is there a significant difference between the means of the compressive strengths of the two cement mortars at a level of significance of 0.10?

Expert Solution & Answer

Want to see the full answer?

Check out a sample textbook solution

Students have asked these similar questions

8.2 only

5.6 A section of highway has the following flow-

density relationship q = 50k - 0.156k2 [with q in veh/h

and k in veh/mi]. What is the capacity of the highway

section, the speed at capacity, and the density when

the highway is at one-quarter of its capacity?

8.20 Two routes connect a suburban area and a city,

with route travel times (in minutes) given by the

expressions t₁ = 6 + 8(x₁/c₁) and t₂ = 10 + 3(x2/c2),

where the x's are expressed in thousands of vehicles

per hour and the c's are the route capacities in

thousands of vehicles per hour. Initially, the

capacities of routes 1 and 2 are 4000 and 2000 veh/h,

respectively. A reconstruction project on route 1

reduces the capacity to 3000 veh/h, but total traffic

demand is unaffected. Observational studies note a

35.28-second increase in average travel time on route

1 and a 68.5% increase in flow on route 2 after

reconstruction begins. User-equilibrium conditions

exist before and during reconstruction. If both routes

are always used, determine equilibrium flows and

travel times before and after reconstruction begins.

Chapter 6 Solutions

Materials for Civil and Construction Engineers (4th Edition)

Ch. 6 - What ingredients are used for the production of...Ch. 6 - What is the role of gypsum in the production of...Ch. 6 - What is a typical value for the fineness of...Ch. 6 - What are the primary chemical reactions during the...Ch. 6 - Define the C-S-H phase of cement paste.Ch. 6 - What are the four main chemical compounds in...Ch. 6 - Prob. 6.7QPCh. 6 - Define a. interlayer hydration space b. capillary...Ch. 6 - Prob. 6.9QPCh. 6 - The following laboratory tests are performed: a....

Ch. 6 - What is a false set of portland cement? State one...Ch. 6 - The watercement ratio is important because it...Ch. 6 - Discuss the effect of watercement ratio on the...Ch. 6 - Draw a graph to show the general relationship...Ch. 6 - Students in the materials class prepared three...Ch. 6 - Students in the materials class prepared three...Ch. 6 - Two batches of cement mortar with properties as...Ch. 6 - What are the five primary types and functions of...Ch. 6 - Why isnt pozzolan used with Type III cement?Ch. 6 - What type of cement would you use in each of the...Ch. 6 - In order to evaluate the suitability of nonpotable...Ch. 6 - Three standard mortar cubes were made using...Ch. 6 - Four standard mortar cubes were made using...Ch. 6 - Discuss the problem of disposal of waste water...Ch. 6 - State five types of admixtures and discuss their...Ch. 6 - Prob. 6.27QPCh. 6 - Under what condition is an air-entraining agent...Ch. 6 - If a water reducer is added to the concrete mix...Ch. 6 - Prob. 6.30QPCh. 6 - A concrete mix includes the following ingredients...Ch. 6 - The results of an experiment to evaluate the...Ch. 6 - The results of a laboratory experiment to evaluate...Ch. 6 - Referring to Table P6.34, Mix No. 1 was designed...Ch. 6 - Two batches of concrete cylinders were made with...Ch. 6 - Two batches of concrete cylinders were made with...Ch. 6 - What is the source of fly ash? Why is fly ash...Ch. 6 - A materials engineer is working in a research...Ch. 6 - A materials engineer is working in a research...

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, civil-engineering and related others by exploring similar questions and additional content below.Similar questions

- 8.19 Three routes connect an origin and a destination with performance functions t₁ = 8+ 0.5x1, t2 = 1 + 2x2, and t3 = 3 + 0.75x3, with the x's expressed in thousands of vehicles per hour and the 's expressed in minutes. If the peak-hour traffic demand is 3400 vehicles, determine user-equilibrium traffic flows.arrow_forward8.8 onlyarrow_forward8.4 Consider a Poisson regression model for the number of social/recreational trips generated during a peak-hour period that is estimated by (see Eq. 8.3) BZ = -0.75 +0.025(household size) + 0.008(annual household income, in thousands of dollars) + 0.10(number of nonworking household members). Suppose a household has five members (three of whom work) and an annual income of $100,000. What is the expected number of peak-hour social/recreational trips, and what is the probability that the household will not make a peak-hour social/recreational trip?arrow_forward

- 8.15 An origin-destination pair is connected by a route with a performance function t₁ = 8+ x1, and another with a function t₂ = 1 + 2x2 (with x's in thousands of vehicles per hour and t's in minutes). If the total origin-destination flow is 4000 veh/h, determine user-equilibrium and system-optimal route travel times, total travel time (in vehicle minutes), and route flows.arrow_forward8.13 Consider the situation described in Problem 8.11. If the total number of trips remains constant, determine the amount of amusement floor space that must be added to destination 2 to attract an additional 50 social/recreational trips.arrow_forward5- A basic freeway has 3 lanes in each direction and is on flat terrain. It has a jam density of 190 veh/km and a capacity of 4750 veh/h. The spot speed of 5 cars was collected at the midpoint of a 3.4 km segment of this freeway. Vehicle Speed (km/hr) 1 86 2 89 3 95 4 5 99 100 a) Calculate the space mean speed b) Calculate the free flow speed based on the given information c) A directional weekday peak-hour volume of 4640 vehicles is observed, with 1320 vehicles arriving in the most congested 15-min period. If the traffic stream has 12% large trucks and buses determine the level of service 6- What are the steps that a 4-step model used to predict travel demand on roads network consists of? Briefly describe was sort of information each step provides? 7- The bitumen is a conventional bituminous binder has a penetration index of -1 and = 65°c. T800 pen a) Determine the stiffness modulus of this bitumen if the operating conditions are as follows: temperature of 25°c and loading time of…arrow_forward

- Q) Find the location of centroid for the shaded area shown in Figure below. 20mm 42mm 23mm 30mm 30mm 10mm Xarrow_forwardQuestion 5 (Force Method). Determine the reaction at the supports. Assume A is fixed and B and C are rollers. El is constant. 3 k/ft A 10 ft B 2 k/ft 10 ft Carrow_forwardFind the collapse load (Wu) for the one-end continuous beam shown below. Wu 6 marrow_forward

- 4- As part of a highway interchange project, a ramp will be constructed to allow the vehicles exit the first highway and enter the second highway. The first highway runs north-south and the second one had a right angle to the first one (it runs east-west). Vehicles going to the north can use this exit ramp to enter the second highway as shown in the plan view in the figure below. The design speed in both highways is 100 km/hr. The stationing of the start of the horizontal curve is 40+00. a) Determine the stationing of PI and PT¶ b) The first highway has a vertical grade of +3.5% and the second highway has a grade of - 0.5%. The stationing of the beginning and the end of the crest curve are the same as the horizontal curve. What is the elevation of the end of the vertical curve (PVT) if the elevation of the start point (PVC) is 1500m c) Calculate K for the vertical curve Plan view (horizontal alignment) PT 1 N Profile view (vertical alignment) G1=0.5% PVT PC, 40+00 PVC G1=+3.5%arrow_forward10- A pavement with a thin bituminous surface is going to be constructed with a design traffic of 6*105 ESA. Laboratory testing of the subgrade and pavement materials has given the following CBR values. Design the pavement using the empirical design method. Use the and show how you got the numbers on the graph relevant graph} Subgrade CBR: 5 Granular subbase material: Upper layer CBR> 30 Lower layer CBR = 10 Granular base material CBR >100arrow_forward1- Describe the perception-reaction process in driver's decision making. What are the steps this process consists of and what tasks are included in each step? Why this process should be considered in transportation planning 3- What are the three main parts that can be included in a road cross section? Briefly describe what each part is for? Sketch a typical cross sectionarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Steel Design (Activate Learning with these NEW ti...Civil EngineeringISBN:9781337094740Author:Segui, William T.Publisher:Cengage Learning

Steel Design (Activate Learning with these NEW ti...Civil EngineeringISBN:9781337094740Author:Segui, William T.Publisher:Cengage Learning Materials Science And Engineering PropertiesCivil EngineeringISBN:9781111988609Author:Charles GilmorePublisher:Cengage Learning

Materials Science And Engineering PropertiesCivil EngineeringISBN:9781111988609Author:Charles GilmorePublisher:Cengage Learning Fundamentals of Geotechnical Engineering (MindTap...Civil EngineeringISBN:9781305635180Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning

Fundamentals of Geotechnical Engineering (MindTap...Civil EngineeringISBN:9781305635180Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning

Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning Construction Materials, Methods and Techniques (M...Civil EngineeringISBN:9781305086272Author:William P. Spence, Eva KultermannPublisher:Cengage Learning

Construction Materials, Methods and Techniques (M...Civil EngineeringISBN:9781305086272Author:William P. Spence, Eva KultermannPublisher:Cengage Learning Solid Waste EngineeringCivil EngineeringISBN:9781305635203Author:Worrell, William A.Publisher:Cengage Learning,

Solid Waste EngineeringCivil EngineeringISBN:9781305635203Author:Worrell, William A.Publisher:Cengage Learning,

Steel Design (Activate Learning with these NEW ti...

Civil Engineering

ISBN:9781337094740

Author:Segui, William T.

Publisher:Cengage Learning

Materials Science And Engineering Properties

Civil Engineering

ISBN:9781111988609

Author:Charles Gilmore

Publisher:Cengage Learning

Fundamentals of Geotechnical Engineering (MindTap...

Civil Engineering

ISBN:9781305635180

Author:Braja M. Das, Nagaratnam Sivakugan

Publisher:Cengage Learning

Traffic and Highway Engineering

Civil Engineering

ISBN:9781305156241

Author:Garber, Nicholas J.

Publisher:Cengage Learning

Construction Materials, Methods and Techniques (M...

Civil Engineering

ISBN:9781305086272

Author:William P. Spence, Eva Kultermann

Publisher:Cengage Learning

Solid Waste Engineering

Civil Engineering

ISBN:9781305635203

Author:Worrell, William A.

Publisher:Cengage Learning,

Concrete Slab Calculations 006; Author: Jerry Howard;https://www.youtube.com/watch?v=R19jILyBxio;License: Standard Youtube License