Concept explainers

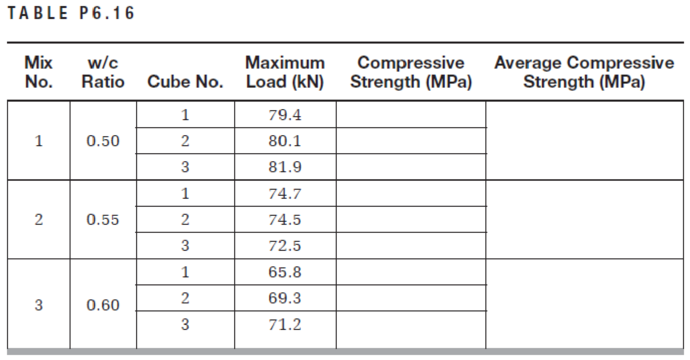

Students in the materials class prepared three mortar mixes with water to cement ratios of 0.50, 0.55, and 0.60. Three 50-mm mortar cubes were prepared for each mix. The cubes were cured for 7 days and then tested for compressive strength. The test results were as shown in Table P6.16.

Determine the following:

a. The compressive strength of each cube.

b. The average compressive strength for each mix.

c. Plot the average compressive strength versus w/c ratios for all mixes.

d. Comment on the effect of increasing w/c ratio on the compressive strength of the cubes.

Want to see the full answer?

Check out a sample textbook solution

Chapter 6 Solutions

Materials for Civil and Construction Engineers (4th Edition)

Additional Engineering Textbook Solutions

Vector Mechanics For Engineers

Management Information Systems: Managing The Digital Firm (16th Edition)

Thermodynamics: An Engineering Approach

Starting Out with Programming Logic and Design (5th Edition) (What's New in Computer Science)

Electric Circuits. (11th Edition)

Database Concepts (8th Edition)

- Determine the collapse load for the simply supported slab. 3 m 3 marrow_forwardm A square slab is simply supported along all sides and is to be isotropically reinforced. Determine the ultimate resisting moment (m) per linear meter required just to sustain a uniformly distributed load (w) in kN/m². marrow_forwardBy using the yield line theory, determine the moment (m) for an isotropic reinforced concrete two-way slab (supports on two S.S sides shown in figure under the load (P) (all dimensions are in mm). m m 2000 2000 3000arrow_forward

- By using the yield line theory, determine the moment (m) for an isotropic reinforced concrete two-way slab shown in figure under a concentrated force (P) on the free corner. The two line supports of slab is simply supports. m m 2000 2000arrow_forward1: Determine the load capacity of the one-way uniformly loaded (5 kN/m²) simply supported slab shown in Fig. 2 m 2 m 1.5 m E Earrow_forward1: Determine the load capacity of the one-way uniformly loaded (5 kN/m²) simply supported slab shown in Fig. Solution: 2 m 2 m هنا الاسناد بسيط، لذلك سيتشكل خط خضوع واحد بالمنتصف ( البلاطة متناظرة) = We [5.0x (2x1.5) 0 = 8/2 :. W;= [m × 8/2 × 1.5] <2 = [1.5m 6] :: We = Wi 15 6 = 1.5 m 6 m = 10 kN.m 8/2] -8=1.0 1.5 m E E L 8/2 δ 28 0 = L/2 Larrow_forward

- A closed tank contains compressed air and oil ( 0.90)OilS = as is shown. A U-tube manometerusing mercury ( 13.6)HgS = is connected to the tank as shown. The column heights are1 2 340 , 8 , 15h cm h cm h cm= = = . Determine the pressure reading (in KPa ) of the gage.(Answer: 15.8AirP KPa= )arrow_forwardA piston is placed in the right side cylinder containing 20 C water as shown in the figure.Determine the height difference ( h∆ ) in liquid surface of both sides.arrow_forwardThe pressure in the air above an oil surface in a tank is 200 Kpa absolute. The absolutepressure 1.5m below the surface of the oil, in KPa is: (5 Points)Present your calculations and select the closest answera) 211.03b) 214.71c) 215.01d) 216.25arrow_forward

- Four container contain the same solution of sodium chloride mixture. The containers are alldifferently shaped but have the same height of fluid relative to the base. At a distance of 20cmabove the base, in which container would the pressure be the highest? Explain.arrow_forward2–6. The square deforms into the position shown by the dashed lines. Determine the shear strain at each of its corners, A, B, C, and D, relative to the x, y axes. Side D′B′ remains horizontal.arrow_forwardThe force P applied at joint D of the square frame causes the frame to sway and form the dashed rhombus. Determine the average normal strain developed in wire AC. Assume the three rods are rigid.arrow_forward

Construction Materials, Methods and Techniques (M...Civil EngineeringISBN:9781305086272Author:William P. Spence, Eva KultermannPublisher:Cengage Learning

Construction Materials, Methods and Techniques (M...Civil EngineeringISBN:9781305086272Author:William P. Spence, Eva KultermannPublisher:Cengage Learning Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning

Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning Materials Science And Engineering PropertiesCivil EngineeringISBN:9781111988609Author:Charles GilmorePublisher:Cengage Learning

Materials Science And Engineering PropertiesCivil EngineeringISBN:9781111988609Author:Charles GilmorePublisher:Cengage Learning Fundamentals Of Construction EstimatingCivil EngineeringISBN:9781337399395Author:Pratt, David J.Publisher:Cengage,

Fundamentals Of Construction EstimatingCivil EngineeringISBN:9781337399395Author:Pratt, David J.Publisher:Cengage, Fundamentals of Geotechnical Engineering (MindTap...Civil EngineeringISBN:9781305635180Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning

Fundamentals of Geotechnical Engineering (MindTap...Civil EngineeringISBN:9781305635180Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning Solid Waste EngineeringCivil EngineeringISBN:9781305635203Author:Worrell, William A.Publisher:Cengage Learning,

Solid Waste EngineeringCivil EngineeringISBN:9781305635203Author:Worrell, William A.Publisher:Cengage Learning,