Concept explainers

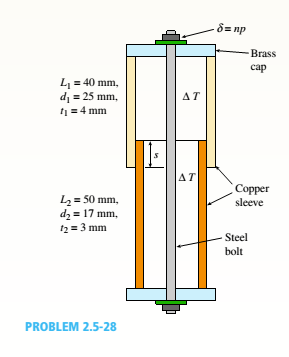

Consider the sleeve made From two copper tubes joined by tin-lead solder over distance s. The sleeve has brass caps at both ends that are held in place by a steel bolt and washer with the nut turned just snug at the outset. Then, two "loadings" are applied: a = 1/2 turn applied to the nut; at the same time, the internal temperature is raised by ?T = 30°C.

(a) Find the forces in the sleeve and boll, Psand PB, due to both the priestess in the bolt and the temperature increase. For copper, use EI= 120 GPa and ac= 17 × W+C; for steel, use E, = 200 GPa and a, = 12 × 10-6/°C. The pitch of the boll threads is p = 1.0 mm. Assume s = 26 mm and bolt diameter dB= 5 mm.

(b) Find the required length of the solder joint, s, if shear stress in the sweated joint cannot exceed the allowable shear stress t ™ 18.5 MPa.

(c) What is the final elongation of the entire assemblage due to both temperature change A T and the initial prestress in the bolt?

(a)

The force on the sleeve and force on the blot.

Answer to Problem 2.5.28P

The force on the sleeve is =

The force on the bolt is =

Explanation of Solution

Given information:

The length of the copper sleeve is

Write the expression for area of bolt.

Here, area of the bolt is

Write the expression for the area of the copper sleeve.

Here, area of the copper sleeve is

Write the expression for the area of steel bolt.

Here, area of steel bolt is

Write the expression for the elongation in bolt.

Here, elongation in bolt is

Write the expression for elongation.

Here, elongation is

Write the compatibility Equation for elongation.

Calculation:

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Since

Conclusion:

The force on the sleeve is

The force on the bolt is

(b)

The required length of the joint.

Answer to Problem 2.5.28P

The required length of the joint is

Explanation of Solution

Given information:

The length of the copper sleeve is

Write the expression for area.

Here, area of sleeve is

Write the expression for allowable shear stress.

Here, allowable shear stress is

Calculation:

Substitute

Substitute

Conclusion:

The required length of joint is

(c)

The final displacement.

Answer to Problem 2.5.28P

The final displacement is

Explanation of Solution

Given information:

The length of the copper sleeve is

Write the expression for displacement in bolt.

Here, the displacement in bolt is

Write the expression for displacement in sleeve.

Here, the displacement in sleeve is

Write the expression for final elongation.

Here, the final elongation is

Calculation:

Substitute

Substitute

Substitute

Conclusion:

The final displacement is =

Want to see more full solutions like this?

Chapter 2 Solutions

Mechanics of Materials (MindTap Course List)

- A capped cast-iron pipe is compressed by a brass rod, as shown. The mil is turned until it is just snug, then add an additional quarter turn to pre-compress the cast-iron pipe. The pitch of the threads of the bolt ap = 52 mils (a mil is one-thousandth of an inch). Use the numerical properties provided. (a) What stresses a and arwill be produced in the cast-iron pipe and brass rod. respectively, by the additional quarter turn of the nut? (b) Find the bearing stress ahbeneath the washer and the shear stress t(in the steel cap.arrow_forwardA pressurized circular cylinder has a sealed cover plate fastened with steel bolts (see figure). The pressure P of the gas in the cylinder is290psi, the inside diameter D of the cylinder is 10.0 in., and the diameter dBof the bolts is 0.50 in. I f the allowable tensile stress in the bolts is 10,000 psi, find the number n of bolts needed to fasten the cover.arrow_forwardA polyethylene tube (length L) has a cap that when installed compresses a spring (with under-formed length L1) by an amount ?? = (L1 = L). Ignore deformations of the cap and base. Use the force at the base of the spring as the redundant. Use numerical properties given in the boxes. (a) What is the resulting Force-in the spring, Fk? (b) What is the resulting Force in the tube, Ftl (c) What is the filial length of the tube, Lf? (d) What temperature change ?T inside the tube will result in zero force in the springarrow_forward

- Two sections of steel drill pipe, joined by bolted flange plates at Ä are being tested to assess the adequacy of both the pipes. In the test, the pipe structure is fixed at A, a concentrated torque of 500 kN - m is applied at x = 0.5 m, and uniformly distributed torque intensity t1= 250 kN m/m is applied on pipe BC. Both pipes have the same inner diameter = 200 mm. Pipe AB has thickness tAB=15 mm, while pipe BC has thickness TBC= 12 mm. Find the maximum shear stress and maximum twist of the pipe and their locations along the pipe. Assume G = 75 GPa.arrow_forwardSolve the preceding problem if the diameter is 480 mm, the pressure is 20 MPa, the yield stress in tension is 975 MPa, the yield stress in shear is 460 MPa, the factor of safety is 2,75, the modulus of elasticity is 210 GPa, Poissorfs ratio is 0.28, and the normal strain must not exceed 1190 x 10" . For part (b), assume that the tank thickness is 8 mm and the measured normal strain is 990 x 10~ .arrow_forwardA hollow, circular, cast-iron pipe (Ec =12,000 ksi) supports a brass rod (Ec= 14,000 ksi} and weight W — 2 kips, as shown. The outside diameter of the pipe is dc= 6 in. (a) If the allowable compressive stress in the pipe is S00O psi and the allowable shortening of the pipe is 0.02 in., what is the minimum required wall thickness trmm? (Include the weights of the rod and steel cap in your calculations.) (b) What is the elongation of the brass rod Srdue to both load Wand its own weight? (c) What is the minimum required clearance h?arrow_forward

- A spherical balloon is filled with a gas. The outer diameter of the balloon is 20 in. and the thickness is 0,012 in. Calculate the maximum permissible pressure in the balloon if the allowable tensile stress and the allowable shear stress in the balloon are 1 ksi and 0.3 ksi, respectively.arrow_forwardA vertical pole of aluminum is fixed at the base and pulled at the top by a cable having a tensile force T(see figure). The cable is attached at the outer edge of a stiffened cover plate on top of the pole and makes an angle a = 20° at the point of attachment. The pole has length a = 2.5 m and a hollow circular cross section with an outer diameter d2= 280 mm and inner diameter d1= 220 mm. The circular cover plate has diameter 1.5d2 Determine the allowable tensile force Tallow in the cable if the allowable compressive stress in the aluminum pole is 90 MPa.arrow_forward-19 The mechanical assembly shown in the figure consists of an aluminum tube, a rigid end plate, and two steel cables. The slack is removed from the cables by rotating the turnbuckles until the assembly is snug but with no initial stresses. Afterward, the turnbuckles are tightened by 1.5 turns. Calculate the forces in the tube and the cables and determine the shortening of the tube. As= 0.85 in2 for each cable, AA= 4.5 in2, L = 20 in., Es= 29,000 ksi, EA= 10,600 ksi, and p = 1/16 inarrow_forward

- Solve the preceding problem if F =90 mm, F = 42 kN, and t = 40°MPaarrow_forwardA cylindrical tank with hemispherical heads is constructed of steel sections that are welded circumferentially (see figure). The tank diameter is 1.25 m, the wall thickness is 22 mm, and the internal pressure is 1750 kPa, (a) Determine the maximum tensile stress h in the heads of the tank. (b) Determine the maximum tensile stress c in the cylindrical part of the tank. (c) Determine the tensile stress <7W acting perpendicular to the welded joints, (d) Determine the maximum shear stress rtiin the heads of the tank. (e) Determine the maximum shear stress tcin the cylindrical part of the tankarrow_forwardA safety valve on the top of a tank containing steam under pressure p has a discharge hole of diameter d(see figure). The valve is designed to release the steam when the pressure reaches the value Pmax If the natural length of the spring, is L and its stiffness is k, what should be the dimension ft of the valve? (Express your result as a formula for h.)arrow_forward

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning