In considering the following problems involving heat transfer in the natural environment (outdoors), recognize that solar radiation is comprised of long and short wave length components. If this radiation is incident on a semi-transparent medium, such as water or glass, two things will happen to the nonreflected portion of the radiation. The long wavelength component will he absorbed at the surface of the medium, whereas the short wavelength component will be transmitted by the surface.

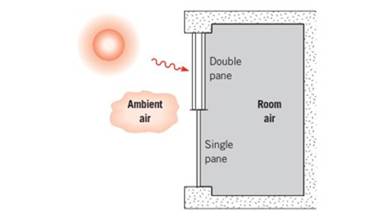

(a) The number of panes in a window can strongly influence the heat loss from a heated room to the outside ambient air. Compare the single- and double-paned units shown by identifying relevant heat transfer processes for each case.

(b) In a typical flat-plate solar collector, energy is collected by a working fluid that is circulated through tubes that are in good contact with the hack face of an absorber plate. The back face is insulated twin the surroundings, and the absorber plate receives solar radiation on its front face, which is typically covered by one or more transparent plates. Identify the relevant heat transfer processes, first for the absorber plate with no cover plate and then for the absorber plate with a single cover plate.

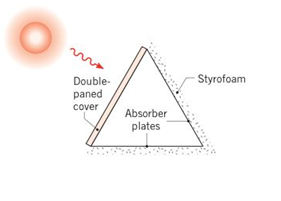

(c) The solar energy collector design shown in the schematic has been used for agricultural applications. Air is blown through a long duct whose cross section is in the form of an equilateral triangle. One side of the triangle is comprised of a double-paned, semitransparent cover; the other two sides are constructed from aluminum sheets painted flat black on the inside and covered on the outside with a layer of styrofoam insulation. During sunny periods, air entering the system is heated for delivery to either a greenhouse, grain drying unit, or storage system.

Identify all heat transfer processes associated with the cover plates, the absorber plate(s), and the air.

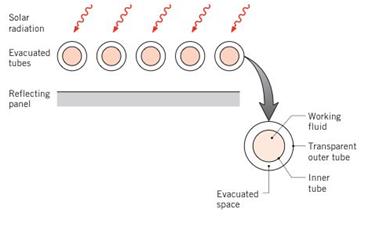

(d) Evacuated-tube solar collectors are capable of improved performance relative to flat-plate collectors. The design consists of an inner tube enclosed in an outer tube that IS transparent to solar radiation. The annular space between the tubes is evacuated. The outer, opaque surface of the inner tube absorbs solar radiation. and a working fluid is passed through the tube to collect the solar energy. The collector design generally consists of a row of such tubes arranged in front of a reflecting panel. Identify all heat transfer processes relevant to the performance of this device.

Want to see the full answer?

Check out a sample textbook solution

Chapter 1 Solutions

Fundamentals of Heat and Mass Transfer

- A garden hose attached with a nozzle is used to fill a 20-gal bucket. The inner diameter of the hose is 1 in and it reduces to 0.53 in at the nozzle exit. The average velocity in the hose is 8 ft/s and the density of water is 62.4 lbm/ft3. NOTE: This is a multi-part question. Once an answer is submitted, you will be unable to return to this part. Determine the volume and mass flow rates of water through the hose. The volume flow rate of water through the hose is ft3/s. The mass flow rate of water through the hose is lbm/s. The change in time? What is the exit velocity?arrow_forwardA 23-ft3 rigid tank initially contains saturated refrigerant-134a vapor at 160 psia. As a result of heat transfer from the refrigerant, the pressure drops to 50 psia. NOTE: This is a multi-part question. Once an answer is submitted, you will be unable to return to this part. Determine the final temperature. Use data from refrigerant tables. The final temperature is ºF.arrow_forwardA 23-ft3 rigid tank initially contains saturated refrigerant-134a vapor at 160 psia. As a result of heat transfer from the refrigerant, the pressure drops to 50 psia. NOTE: This is a multi-part question. Once an answer is submitted, you will be unable to return to this part. Determine the heat transfer. The heat transfer is Btu.arrow_forward

- The shaft shown in the figure below is subjected to axial loads as illustrated. The diameters of segments AB, BC, and CD are 20mm, 25mm, and 15mm, respectively. If the modulus of elasticity of the material is 610 MPa. Determine the change of A to D lengtharrow_forwardDetermine the final pressure and temperature. The final pressure is kPa. The final temperature is ºC.arrow_forwardAir enters the 1-m2 inlet of an aircraft engine at 100 kPa and 20°C with a velocity of 184 m/s. Determine the volume flow rate, in m3/s, at the engine’s inlet and the mass flow rate, in kg/s, at the engine’s exit. The gas constant of air is R = 0.287 kPa·m3/kg·K. The volume flow rate at the engine’s inlet m3/s. The mass flow rate at the engine’s exit is kg/s.arrow_forward

- The ventilating fan of the bathroom of a building has a volume flow rate of 33 L/s and runs continuously. If the density of air inside is 1.20 kg/m3, determine the mass of air vented out in one day. The mass of air is kg.arrow_forwardA steady-flow compressor is used to compress helium from 15 psia and 70°F at the inlet to 200 psia and 600°F at the outlet. The outlet area and velocity are 0.01 ft2 and 100 ft/s, respectively, and the inlet velocity is 53 ft/s. Determine the mass flow rate and the inlet area. The gas constant of helium is R = 2.6809 psia·ft3/lbm·R. The mass flow rate is lbm/s. The inlet area is ft2.arrow_forward1. The maximum and minimum stresses as well as the shear stress seen subjected the piece in plane A-A. Assume it is a cylinder with a diameter of 12.7mm 2. Draw the Mohr circle for the stress state using software. 3. Selection of the material for the prosthesis, which must be analyzed from the point of safety and cost view.arrow_forward

Principles of Heat Transfer (Activate Learning wi...Mechanical EngineeringISBN:9781305387102Author:Kreith, Frank; Manglik, Raj M.Publisher:Cengage Learning

Principles of Heat Transfer (Activate Learning wi...Mechanical EngineeringISBN:9781305387102Author:Kreith, Frank; Manglik, Raj M.Publisher:Cengage Learning