Concept explainers

(a)

The maximum temperature in the cycle.

(a)

Answer to Problem 149P

The maximum temperature in the cycle is

Explanation of Solution

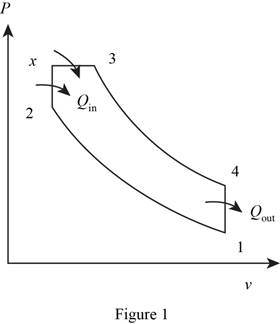

Draw the

Refer to Table A-2b, obtain the properties of air at 1000 K.

Express the compression ratio.

Here, clearance volume is

Express the total volume of the engine at the beginning of compression process (state 1).

Process 1-2: Isentropic compression

Calculate the temperature at state 2.

Here, temperature at state 1 is

Calculate the pressure at state 2.

Here, pressure at state 1 is

Process 2-x and x-3: Constant-volume and constant pressure heat addition processes

Calculate the temperature at x state.

Here, pressure at x state is

Calculate the heat addition to the process 2-x.

Here, constant volume specific heat is

Calculate the heat addition to the process x-3.

Here, constant pressure specific heat is

Conclusion:

Substitute 16 for r and 1.8 L for

The value of

Substitute

Substitute 343 K for

Substitute 95 kPa for

Substitute 3859 kPa for

Substitute

Substitute

Thus, the maximum temperature in the cycle is

(b)

The net work output.

The thermal efficiency.

(b)

Answer to Problem 149P

The net work output is

The thermal efficiency is

Explanation of Solution

Express the total heat addition to the process.

Calculate the volume at state 3.

Here, volume at state x is

Process 3-4: Isentropic expansion

Calculate the temperature at state 4.

Here, volume at state 3 and 4 are

Calculate the pressure at state 4.

Here, pressure at state 3 and 4 are

Process 4-1: Constant volume heat rejection

Calculate the heat rejection.

Calculate the net work output.

Calculate the thermal efficiency.

Conclusion:

Substitute 702.6 kJ/kg for

Substitute

Substitute 2308 K for

Substitute 7500 kPa for

Substitute

Substitute 569.3 kJ/kg for

Thus, the net work output is

Substitute 835.8 kJ/kg for

Thus, the thermal efficiency is

(c)

The mean effective pressure.

(c)

Answer to Problem 149P

The mean effective pressure is

Explanation of Solution

Calculate the mass.

Calculate the mean effective pressure.

Conclusion:

Substitute 95 kPa for

Substitute 0.001853 kg for m,

Thus, the mean effective pressure is

(d)

The power for engine speed of 3500 rpm.

(d)

Answer to Problem 149P

The power for engine speed of 3500 rpm is

Explanation of Solution

Calculate the power for engine speed of 3500 rpm.

Here, engine speed is

Conclusion:

Substitute 2200 rev/min for

Thus, the power for engine speed of 3500 rpm is

(e)

The second law efficiency of the cycle.

The rate of exergy output with the exhaust gases.

(e)

Answer to Problem 149P

The second law efficiency of the cycle is

The rate of exergy output with the exhaust gases is

Explanation of Solution

Express the maximum thermal efficiency of the cycle.

Here, dead state temperature is

Express the second law efficiency of the cycle.

Calculate the rate of exergy of the exhaust gases.

Here, specific internal energy at state 4, dead state is

Conclusion:

Substitute

Substitute 0.8709 for

Thus, the second law efficiency of the cycle is

Substitute

Thus, the rate of exergy output with the exhaust gases is

Want to see more full solutions like this?

Chapter 9 Solutions

Thermodynamics: An Engineering Approach

- Suppose that a steel of eutectoid composition is cooled to 675°C (1250°F) from 760°C (1400°F) in less than 0.5 s and held at this temperature. (a) How long will it take for the austenite-topearlite reaction to go to 50% completion? To 100% completion? (b) Estimate the hardness of the alloy that has completely transformed to pearlite.arrow_forwardProblem 2: Determine the components of the reaction at point B (Please use paper sheet + FBD ,don't use chatgpt) MECHANICAL ENGGarrow_forwardARL040_AE_Kn_2of3... Dor Question 4. A two-throw crankshaft has masses distributed as shown: RAH 90 rpm A TRAV B Re Rev M₁ = 15kg; M₂ = 12kg L = 950mm; 1, 350mm; 1₁ = 600mm; 0₁ = 90°; 02=0°; r₁ = 300mm; r250mm The crankshaft is to be balanced by attaching masses at radii of 300 mm and rotating in planes 150 mm outside the planes of number one and number two cranks. Determine the magnitude and angular position of the balance masses. Answer 4.arrow_forward

- FEAarrow_forwardFinite Element Analysisarrow_forwardan experimental research station is constructed on a concrete slab floor. The heat loss from the floor slab is significant, given the cold environment, and is measured to be 5 kW. The edges of the floor slab are insulated with a 60 mm thickness of cellular glass insulation. The width of this insulation at the floor slab is 0.9 m. To avoid excessive fuel consumption, the station air temperature is maintained at a slightly cool temperature of 18ºC. The station is constructed in a square shape, to keep the surface area to volume ratio low; the horizontal dimensions of the floor of the station are 20 m by 20 m. The number of occupants in the research station varies between 5 and 20, depending on the research workload.a) Determine the design outdoor temperature that was used in designing the research station.b) If the floor dimensions of the station are changed to 15 m by 25 m, would the design outdoor temperature that was used in designing the research station from part (a) change? If so,…arrow_forward

- Finite element analysisarrow_forwarda station is constructed on a concrete slab floor. The heat loss from the floor slab is significant, given the cold environment, and is measured to be 5 kW. The edges of the floor slab are insulated with a 60 mm thickness of cellular glass insulation. The width of this insulation at the floor slab is 0.9 m. To avoid excessive fuel consumption, the station air temperature is maintained at a slightly cool temperature of 18ºC. The station is constructed in a square shape, to keep the surface area to volume ratio low; the horizontal dimensions of the floor of the station are 20 m by 20 m. The number of occupants in the research station varies between 5 and 20, depending on the research workload.a) Determine the design outdoor temperature that was used in designing the research station.b) If the floor dimensions of the station are changed to 15 m by 25 m, would the design outdoor temperature that was used in designing the research station from part (a) change? If so, what would it be?…arrow_forwardFinite Element Analysisarrow_forward

- Finite Element Analysisarrow_forwardA small auditorium that can accommodate 30 people allows smoking. The design engineers of the auditorium assume that the smokers each are responsible for an average of 50 micrograms per minute of tobacco smoke being added to the auditorium space. The volumetric flow rate of recirculated room air is 200 cfm. Outdoor air is also supplied, and is mixed with the recirculated room air. The system has a ventilation effectiveness of 80%. In an effort to maintain the level of particulate matter from the tobacco smoke in the auditorium to no more than 5.5 micrograms per cubic foot, filters with an effective efficiency of 90% are added to the ventilation system downstream of the point in the system where outdoor air and recirculated room air are mixed. a) What is the necessary volumetric flow rate (in cfm) for the supply outdoor air? Assume the outdoor air is clean. b) The outdoor air taken into the system becomes contaminated with tobacco smoke due to a leak in an adjacent building’s…arrow_forwardroom to be maintained with a dry-bulb temperature of 72ºF and 30% relative humidity. The room has a sensible heat factor of 0.8 and a total hourly heating load of 200,000 Btu. A flow rate of 1000 cfm of outdoor air (at 20% relative humidity and a dry-bulb temperature of 40ºF) is used. In order to maintain adequate comfort, the supply air to the room is set to a dry-bulb temperature of 120ºF. To humidify the air, steam with a specific enthalpy of 1150 Btu per pound is utilized.Determine the wet bulb temperature, specific enthalpy, and volumetric flow rate of the supply air to the room. Evaluate the increase in dry-bulb temperature as the air is sensibly heated, and the mass flow rate (in lb/hr) of steam required during the latent heating of the air. Calculate the heat added to the room during sensible heating (i.e., excluding humidification).arrow_forward

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY