Operations Management: Sustainability and Supply Chain Management (12th Edition)

12th Edition

ISBN: 9780134130422

Author: Jay Heizer, Barry Render, Chuck Munson

Publisher: PEARSON

expand_more

expand_more

format_list_bulleted

Concept explainers

Textbook Question

Chapter 9, Problem 3P

Three departments—milling (M), drilling (D), and sawing (S)—are assigned to three work areas in Victor Berardis’s machine shop in Vent, Ohio. The number of work pieces moved per day and the distances between the centers of the work areas, in feet, follow.

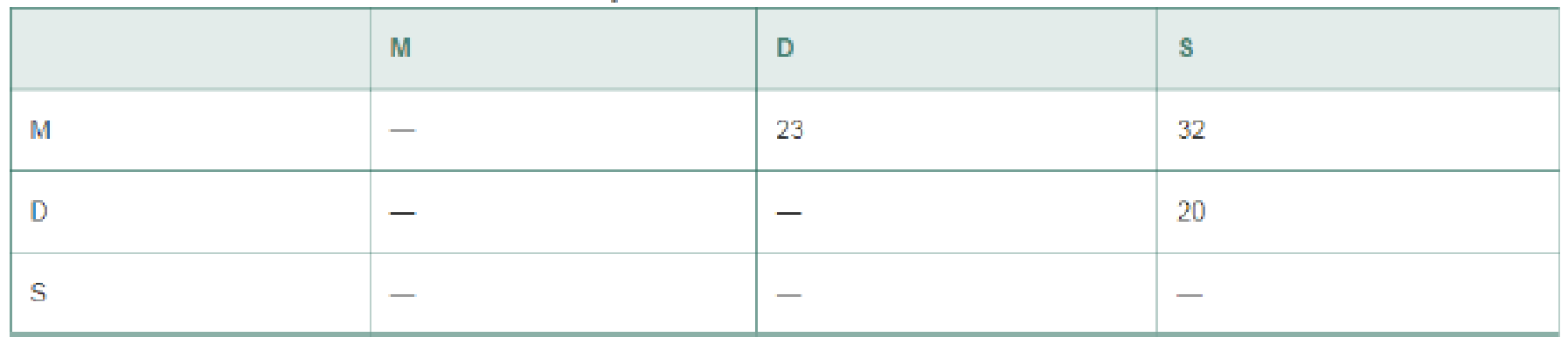

Pieces Moved Between Work Areas Each Day

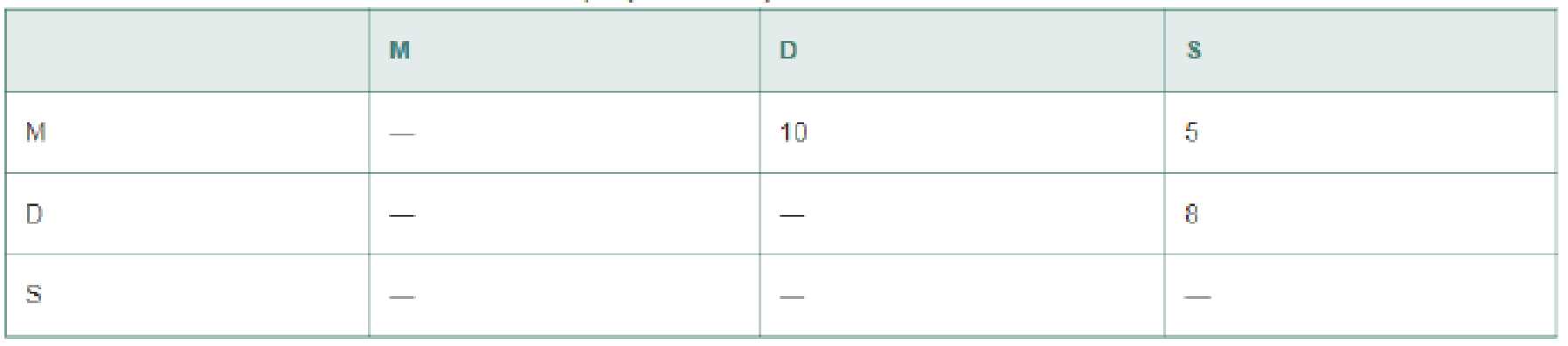

Distances Between Centers of Work Areas(Departments) in Feet

It costs $2 to move 1 workpiece 1 foot.

What is the cost?

Expert Solution & Answer

Want to see the full answer?

Check out a sample textbook solution

Students have asked these similar questions

Three departments- milling (M), drilling (D), andsawing (S)- are assigned to three work areas in Victor Berardis'smachine shop in Kent, Ohio. The number of workpieces movedper day and the distances between the centers of the work areas,in feet, follow. Pieces Moved between Work Areas Each Day lt costs $2 to move I workpiece I foot.What is the cost?

Manufacturing Company uses FIFO method of accumulating costs in a two-department process. Materials are introduced at the inception of the process except for a special material which is added in department 2 at 60% completion as to overhead. Inspection is done at the end of the process in both departments. Production data for Department 2 are given below:

In process, beginning, (80% labor, 70% overhead)2,000 Transferred in 14,900 In process, ending (40% labor, 20% overhead) 3,000 Normal spoilage 200 Abnormal spoilage (found at 30% completion as to laborand 15% as to overhead due to internal failure) 400 Cost data for the month:In process beginning:Transferred in 15,020 Special materials 1,900 Direct labor 4,388 Overhead 11,044 Current costs:Transferred in 137,080 Special materials 14,030 Direct labor 46,000 Overhead 113,564

The cost of units transferred to finished goods is?The cost of spoilage charged to revenue is?

A company is setting up an assembly line to produce 90 units per hour. The table below identifies the work elements, times, and immediate predecessors.

Work Element

Time (Sec.)

Immediate Predecessor(s)

A

25

-

B

18

A

C

20

A

D

5

B, C

E

12

C

F

8

E

G

16

D, F

H

12

G

What cycle time is required to satisfy the required output?

What is the theoretical minimum number of stations?

Chapter 9 Solutions

Operations Management: Sustainability and Supply Chain Management (12th Edition)

Ch. 9 - Prob. 1DQCh. 9 - Prob. 2DQCh. 9 - Prob. 3DQCh. 9 - Prob. 4DQCh. 9 - Prob. 5DQCh. 9 - Prob. 6DQCh. 9 - Prob. 7DQCh. 9 - Prob. 8DQCh. 9 - What are the requirements for a focused work...Ch. 9 - Prob. 10DQ

Ch. 9 - Prob. 11DQCh. 9 - Prob. 12DQCh. 9 - Prob. 13DQCh. 9 - Prob. 14DQCh. 9 - Prob. 15DQCh. 9 - Prob. 16DQCh. 9 - Explain the concept of cross-docking.Ch. 9 - What is a heuristic? Name several that can be used...Ch. 9 - Prob. 1PCh. 9 - Prob. 2PCh. 9 - Three departmentsmilling (M), drilling (D), and...Ch. 9 - Roy Creasey Enterprises, a machine shop, is...Ch. 9 - Prob. 5PCh. 9 - Prob. 6PCh. 9 - Prob. 7PCh. 9 - Prob. 8PCh. 9 - Six processes are to be laid out in six areas...Ch. 9 - After an extensive product analysis using group...Ch. 9 - Stanford Rosenberg Computing wants to establish an...Ch. 9 - Illinois Furniture, Inc., produces all types of...Ch. 9 - Sue Helms Appliances wants to establish an...Ch. 9 - The Action Toy Company has decided to manufacture...Ch. 9 - The following table details the tasks required for...Ch. 9 - Tailwind, Inc., produces high-quality but...Ch. 9 - Prob. 18PCh. 9 - Because of the expected high demand for Mach 10,...Ch. 9 - Prob. 20PCh. 9 - Suppose production requirements in Solved Problem...Ch. 9 - The preinduction physical examination given by the...Ch. 9 - Samuel Smith's company wants to establish an...Ch. 9 - As the Cottrell Bicycle Co. of St. Louis completes...Ch. 9 - Prob. 1CSCh. 9 - Prob. 2CSCh. 9 - Prob. 3CSCh. 9 - Prob. 4CSCh. 9 - Prob. 1.1VCCh. 9 - Prob. 1.2VCCh. 9 - Prob. 1.3VCCh. 9 - Prob. 1.4VCCh. 9 - Prob. 1.5VCCh. 9 - Prob. 1.6VCCh. 9 - Prob. 2.1VCCh. 9 - Prob. 2.2VCCh. 9 - Prob. 2.3VC

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, operations-management and related others by exploring similar questions and additional content below.Similar questions

- The workstation cycle time is 120 seconds with 4 work stations (Tasks A-C, B-E, B-F, G-H). Figure out the idle time for each workstation. Use the table for product task times as a reference.arrow_forwardA computer factory in Tangerang plans to increase production line for new products and plan to produce as many as XX0 units per hour. Production process, production time and production process to continue the next production process are described in the table below: (1 day = 8 working hours) production process production time Production process that follows the next production according to the list below A 12 - B 15 A C 8 A D 5 B,C E 20 D a. What is the cycle time for the production of the new product? ( note : in second )b. What is the minimum number of workstations?c. Draw a diagram of the production process.d. Is it with the diagram that you have drawn, the production process can go according to plan? Describe the process from each workstation you've created!arrow_forwardFrancis Johnson’s plant needs to design an efficient assembly line to make a new product. The assembly line needs to produce 15 units per hour, and there is room for only four workstations. The tasks and the order in which they must be performed are shown in the following table. Tasks cannot be split, and it would be too expensive to duplicate any task. TASK TASK TIME (MINUTES) IMMEDIATE PREDECESSOR A 1 — B 2 — C 3 — D 1 A, B, C E 3 C F 2 E G 3 E What is the workstation cycle time required to produce 15 units per hour? Note: Round your answer to 1 decimal place. Balance the line to use the fewest possible workstations to meet the cycle time found in part (b). Use whatever method you feel is appropriate. What is the efficiency of your line balance, assuming the line operates at the cycle time from part (b)? Note: Round your answer to 1 decimal place.arrow_forward

- QRS Corp is designing a product layout for a new product. They plan to use this production line 9 hours a day in order to meet forecasted demand of 600 units per day. Calculate the cycle time in seconds.. Calculate the minimum number of work stations if the sum of the task times is 170 secs Edit Format Table 12pt v Paragraph v BI UAV MacBook Air 80 esc F3 F5 F6 F7 FB F9 F1 F2 F4 @ # $ & 2 3 7 8 W R IIIY この COarrow_forwardPvnarrow_forwardTailwind, Inc., produces high-quality but expensive training shoes for runners. The Tailwind shoe, which sells for $210, contains both gas- and liquid-filled compartments to provide more stability and better protection against knee, foot, and back injuries. Manufacturing the shoes requires 10 separate tasks. There are 400 minutes available for manufacturing the shoes in the plant each day. Daily demand is 60. The information for the tasks is as follows: Performance Time Task (in minutes) 1 Н ABCDEFGH Task Must Follow This Task C, D ABB GAFG 324-325- E, H 25 312 | Required: a. Draw the precedence diagram showing the task precedence and their times b. Determine the cycle time associated with the rate of output required. c. What is the theoretical minimum number of work stations required to satisfy this output rate? d. Allocate the tasks to work stations taking into consideration the precedence requirements and using the LOT rule to break ties between feasible tasks. e. What is the…arrow_forward

- Statement of the ProblemKuala Lumpur Hospital, as we all know, is one of Malaysia's busiest hospitals. This is due to the fact that it admits a diverse range of patients suffering from a diverse range of disorders. These patients have arrived as a result of the health sector that operates in this facility. In other words, the departments within it are quite diverse. As a result, the hospital must deal with a high volume of both existing and new patients. Employees are required to gather patient personal information such as name, address, and so on for all of these admissions. It intends to capture and save their data for further use. Employee admissions, such as physicians and nurses, should also be recorded by the hospital. Furthermore, the hospital must manually record the many departments, rooms, and physicians in hospitals. It is also required to keep frequent records of patients, patients admitted to the hospital, doctor exams on patients, patients who have had surgery, and…arrow_forwardThe M–N plant manufactures two different products: M and N. Selling prices and weekly market demands are shown in the following diagram. Each product uses raw materials with costs as shown. The plant has three different machines: A, B, and C. Each performs different tasks and can work on only one unit of material at a time. Process times for each task are shown in the diagram. Each machine is available 2,500 minutes per week. There are no "Murphys" (major opportunities for the system to foul up). Setup and transfer times are zero. Demand is constant. Operating expenses (including labor) total a constant $12,000 per week. Raw materials are not included in weekly operating expenses. a. Which machine is the constraint in this plant? multiple choice Machine A Machine C Machine B Incorrectarrow_forwardCanine Kernels Company (CKC) manufactures two different types of dog chew toys (A and B, sold in 1,000-count boxes) that are manufactured and assembled on three different workstations (W, X, and Y) using a small-batch process (see Figure). Batch setup times are negligible. The flowchart denotes the path each product follows through the manufacturing process, and each product’s price, demand per week, and processing times per unit are indicated as well. Purchased parts and raw materials consumed during production are represented by inverted triangles. CKC can make and sell up to the limit of its demand per week; no penalties are incurred for not being able to meet all the demand. Each workstation is staffed by a worker who is dedicated to work on that workstation alone, and is paid $6 per hour. Total labor costs per week are fixed. Variable overhead costs are $3,500/week. The plant operates one 8-hour shift per day, or 40 hours/week. Which of the three workstations, W, X, or Y, has the…arrow_forward

- Questions 67, 68, 69arrow_forwardCanine Kennels Company (CKC) manufactures two different types of dog chew toys (A and B, sold in 1,000-count boxes) that are manufactured and assembled on three different workstations (W, X, and Y) using a small-batch process (see the figure below). Batch setup times are negligible. The flowchart denotes the path each product follows through the manufacturing process, and each product's price, demand per week, and processing times per unit are indicated as well. Purchased parts and raw materials consumed during production are represented by inverted triangles. CKC can make and sell up to the limit of its demand per week; no penalties are incurred for not being able to meet all the demand. Each workstation is staffed by a worker who is dedicated to work on that workstation alone and is paid $10 per hour. Total labor costs per week are fixed. Variable overhead costs are $3,500/week. The plant operates one 8-hour shift per day, or 40 hours/week. Product A $4 Raw materials Product B $7 Raw…arrow_forwardCanine Kennels Company (CKC) manufactures two different types of dog chew toys (A and B, sold in 1,000-count boxes) that are manufactured and assembled on three different workstations (W, X, and Y) using a small-batch process (see the figure below). Batch setup times are negligible. The flowchart denotes the path each product follows through the manufacturing process, and each product's price, demand per week, and processing times per unit are indicated as well. Purchased parts and raw materials consumed during production are represented by inverted triangles. CKC can make and sell up to the limit of its demand per week; no penalties are incurred for not being able to meet all the demand. Each workstation is staffed by a worker who is dedicated to working on that workstation alone and is paid $6 per hour. Total labor costs per week are fixed. Variable overhead costs are $3,500/week. The plant operates one 8-hour shift per day or 40 hours/week. Which of the three workstations, W, X, or…arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Inventory Management | Concepts, Examples and Solved Problems; Author: Dr. Bharatendra Rai;https://www.youtube.com/watch?v=2n9NLZTIlz8;License: Standard YouTube License, CC-BY