(a)

The design of a three-plate moment connection of a

Answer to Problem 8.6.4P

Use a

1/8-in. fillet weld on both sides of the plate.

Use a

Explanation of Solution

Given:

Service dead-load moment = 42 ft-kips

Service live-load moment = 104 ft-kips

Service dead-load beam reaction = 8 kips

Service live-load beam reaction = 21 kips

Group A bearing type bolts

E70 electrodes

A992 steel- Beam and column

A36 steel- Plate material

Calculation:

Reaction:

Moment:

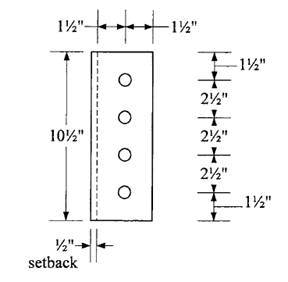

Web plate:

Neglect eccentricity.

Try 5/8-in. diameter bolts.

Assume that threads are in the plane of shear.

Shear capacity of one bolt is

Number of bolts required is

Try 4 bolts.

Determine plate thickness required for bearing. Assume that

Load resisted by each bolt =

Let

Try

Determine whether plate or beam web controls bearing. For the plate,

For the beam web,

Therefore, plate controls.

Check bearing strength assumption:

For the hole nearest the edge, minimum

Try

Therefore, use

For other bolts, minimum

Use

Therefore, use

Bearing controls over shear at each bolt location. Total strength is

Use four 5/8-in. diameter Group A bolts.

Determine plate thickness required for shear:

Shear yielding strength is

Let

Try

Check shear rupture strength:

Use hole diameter =

Check block shear:

Shear areas:

Tension area:

with an upper limit of

The nominal block shear strength is therefore 64.92 kips. The design block shear strength is

Use a

Connection of shear plate to column flange:

Use E70 electrodes

Minimum weld size, based on the plate thickness, is 1/8-in. try

Weld strength =

Base metal (plate) shear strength:

Yielding:

Rupture:

Total length required =

Use a continuous 1/8-in. fillet weld, both sides of plate.

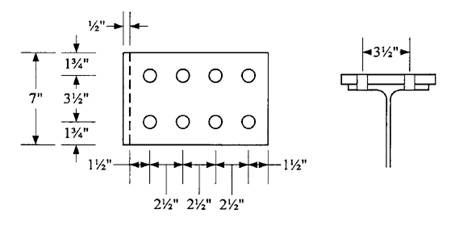

Flange plate:

From

Try 7/8-in. diameter bolts.

Assume that threads are in the plane of shear.

Number of bolts required for shear is

Try 8 bolts (4 pair)

Determine plate thickness required for bearing:

Minimum

Use

Minimum

Use

For the hole nearest the edge,

Therefore, use

For other bolts,

Therefore, use

Total connection strength =

Let

Design top flange plate as a tension connection element

Tension on gross area:

Required

Tension on net area:

Required

Try a plate width of

For gross area requirement,

For net area requirement,

Hole diameter =

Try a plate

Check compression in the bottom plate:

Assume that the plate acts as a fixed-end compression member between the end fastener and the weld. Use

For compression elements with

Therefore,

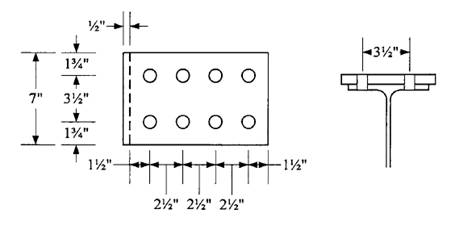

Check block shear on the plate using the dimensions and bolt layout shown.

Shear areas:

Tension area:

with an upper limit of

The nominal block shear strength is therefore 395.9 kips. The design block shear strength is

Check block shear strength of beam flange:

Transverse spacing = gauge distance = 3.5 in.

Transverse edge distance =

Longitudinal spacing and edge distance same as for plate.

Shear areas:

Tension area:

with an upper limit of

The nominal block shear strength is therefore 199.7 kips.

The design block shear strength is

Check beam for the effect of bolt holes in the tension flange:

The gross area of one flange is

The effective hole diameter is

Since

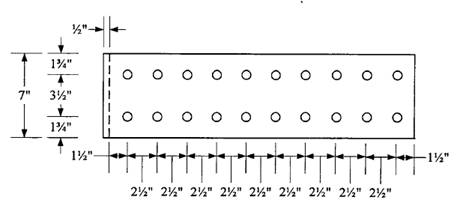

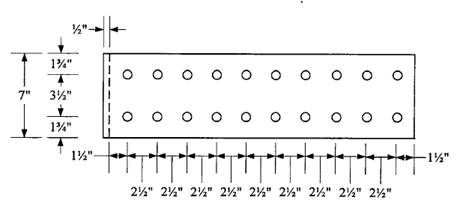

Try a smaller diameter bolt. Try ½-in. diameter bolts.

Normal shearing strength =

Number of bolts required for shear is

Try 20 bolts (10 pair)

Bearing and block shear will be satisfactory.

Check reduction in beam flange area:

Use a hole diameter =

Since

Plate length =

Conclusion:

Use a

(b)

The design of a three-plate moment connection of a

Answer to Problem 8.6.4P

Use a

1/8-in. fillet weld on both sides of the plate.

Use a

Explanation of Solution

Given:

Service dead-load moment = 42 ft-kips

Service live-load moment = 104 ft-kips

Service dead-load beam reaction = 8 kips

Service live-load beam reaction = 21 kips

Group A bearing type bolts

E70 electrodes

A992 steel- Beam and column

A36 steel- Plate material

Calculation:

Reaction:

Moment:

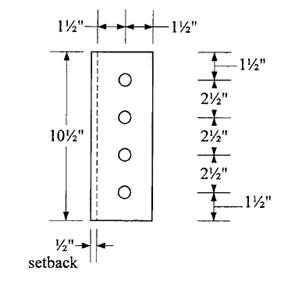

Web plate:

Neglect eccentricity.

Try 5/8-in. diameter bolts.

Assume that threads are in the plane of shear.

Shear capacity of one bolt is

Number of bolts required is

Try 4 bolts.

Determine plate thickness required for bearing. Assume that

Load resisted by each bolt =

Let

Try

Determine whether plate or beam web controls bearing. For the plate,

For the beam web,

Therefore, plate controls.

Check bearing strength assumption:

For the hole nearest the edge, minimum

Try

Therefore, use

For other bolts, minimum

Use

Therefore, use

Bearing controls over shear at each bolt location.

Total strength is

Use four 5/8-in. diameter Group A bolts.

Determine plate thickness required for shear:

Shear yielding strength is

Let

Try

Check shear rupture strength:

Use hole diameter =

Check block shear:

Shear areas:

Tension area:

with an upper limit of

The nominal block shear strength is therefore 64.92 kips. The design block shear strength is

Use a

Connection of shear plate to column flange:

Use E70 electrodes.

Minimum weld size, based on the plate thickness, is 1/8-in. try

Weld strength =

Base metal (plate) shear strength:

The allowable shear yield strength per unit length is

The base metal allowable shear rupture strength per unit length is

Total length required =

Use a continuous 1/8-in. fillet weld, both sides of plate.

Flange plate:

From

Try 7/8-in. diameter bolts.

Assume that threads are in the plane of shear.

Number of bolts required for shear is

Try 8 bolts (4 pair)

Determine plate thickness required for bearing:

Minimum

Use

Minimum

Use

For the hole nearest the edge,

Therefore, use

For other bolts,

Therefore, use

Total connection strength =

Let

Design top flange plate as a tension connection element

Tension on gross area:

Required

Tension on net area:

Required

Try a plate width of

For gross area requirement,

For net area requirement,

Hole diameter =

Try a plate

Check compression in the bottom plate:

Assume that the plate acts as a fixed-end compression member between the end fastener and the weld. Use

For compression elements with

Therefore,

Check block shear on the plate using the dimensions and bolt layout shown.

Shear areas:

Tension area:

with an upper limit of

The nominal block shear strength is therefore 395.9 kips. The design block shear strength is

Check block shear strength of beam flange:

Transverse spacing = gauge distance = 3.5 in.

Transverse edge distance =

Longitudinal spacing and edge distance same as for plate.

Shear areas:

Tension area:

with an upper limit of

The nominal block shear strength is therefore 199.7 kips.

The design block shear strength is

Check beam for the effect of bolt holes in the tension flange:

The gross area of one flange is

The effective hole diameter is

Since

Try a smaller diameter bolt. Try ½-in. diameter bolts.

Normal shearing strength =

Number of bolts required for shear is

Try 20 bolts (10 pair)

Bearing and block shear will be satisfactory.

Check reduction in beam flange area:

Use a hole diameter =

Since

Plate length =

Conclusion:

Use a

Want to see more full solutions like this?

Chapter 8 Solutions

Steel Design (Activate Learning with these NEW titles from Engineering!)

- Determine forces in members BC, GF and CG and nature of forces 9 m D 4 m C 4m 500 F 4 kN 6 kN 4 m 3 m B3 G E Assignment-2 Aarrow_forwardFind forces in all members of the truss shown in Fig. Also find reactions at supports. 12 kN 20 kN ΙΟΧΟΙΟΙ 2 m 2 m 2 m 3 m C G E 4 m B Determine forces in members BC, GF and CG and nature of forces 9 m D 4 m C 4 m F 4 kN 6 kN 4 m 3 m B3 C E Assignment-2arrow_forwardPart 3: Problem-Solving. Solve the following problems. Show all calculations. 1. A retaining wall 5.80m high supports soil that has the following properties: Unit weight = 17.3 kN/m³ Angle of internal friction = 26 deg. Cohesion = 14.5 kPa a) Calculate the normal pressure acting at the back of the wall assuming no tensile crack occurs in the soil. b) Find the location of the tensile crack measured from the surface of horizontal backfill. c) Determine the active pressure acting on the wall in tensile crack occurs in the soil. 2. The soil material is supported by a retaining wall to a height of 6m. The unit weight of the soil is 16 kN/m³ and the angle of internal friction is 29 deg. Assume the soil is cohesionless. a) Determine the earth pressure on the wall. b) Find the total active pressure if surcharge of 14 kPa is applied on the surface of horizontal backfill. c) Locate the position of the total pressure from the bottom.arrow_forward

- Question 3 (20 points): The traffic volume on a 2-lane highway is 1600 veh/hr in each direction Page 3 of 6 with a density of 20 veh/mi. A large dump truck enters the traffic stream from an adjacent construction site at 20 mph and carries on this way for 2 miles before turning off to the dump site. Because flow is so high in the opposite direction, no one can pass the truck. As a result, traffic back up behind the truck at four times the density (i.e., 4x20 = 80 veh/mi) at a volume of 1000 veh/hr. How many vehicles get caught in the traffic congestion before the truck exits the highway?arrow_forwardHow can construction project managers find a balance between speeding up schedules and the risks of making more mistakes and needing rework, especially when using methods like fast tracking?arrow_forwardHelp i keep getting the wrong answer. So I must be doing something wrong.arrow_forward

- 6000 units have been installed to date with 9,000 units to install. Labor costs are $23,300.00 to date. What is the unit cost for labor to date?arrow_forwardThe base rate for labor is $15/hr. The labor burden is 35% and 3% for small tools for the labor. There are 1000 units to install. Records indicate that trade workers can install 10 units per hour, per trade worker. The owners need 15% overhead and profit to pay bills, pay interest on loan and provide some profit to the partners. What is the minimum bid assuming no risk avoidance factor?arrow_forwardCan you show me how to obtain these answers thanks, will rate!arrow_forward

Steel Design (Activate Learning with these NEW ti...Civil EngineeringISBN:9781337094740Author:Segui, William T.Publisher:Cengage Learning

Steel Design (Activate Learning with these NEW ti...Civil EngineeringISBN:9781337094740Author:Segui, William T.Publisher:Cengage Learning