Steel Design (Activate Learning with these NEW titles from Engineering!)

6th Edition

ISBN: 9781337094740

Author: Segui, William T.

Publisher: Cengage Learning

expand_more

expand_more

format_list_bulleted

Concept explainers

Textbook Question

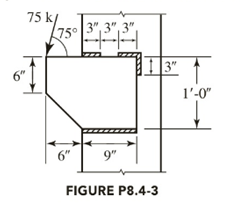

Chapter 8, Problem 8.4.3P

Use an elastic analysis and determine the maximum load per inch of weld.

Expert Solution & Answer

Trending nowThis is a popular solution!

Students have asked these similar questions

Would impulse be zero since the particles have no external forces acting during the moment of contact? Please solve the entire problem.

By using the yield line theory, determine the ultimate resisting moment per linear meter (m) for an

isotropic reinforced concrete two-way simply supported triangle slab shown in figure under a

uniform load (q). Solve by using

equilibrium method

m

m

The tension in cable BA is 10 kN. The questions will lead you toward determining the moment of

the force acting from B to A about the x-axis. Hints: Pay attention to the orientation of the XYZ

coordinate axes.

1000 mm

A

(400, 300, 0) mm

600 mm

x

Chapter 8 Solutions

Steel Design (Activate Learning with these NEW titles from Engineering!)

Ch. 8 - Prob. 8.2.1PCh. 8 - Prob. 8.2.2PCh. 8 - A plate is used as a bracket and is attached to a...Ch. 8 - Prob. 8.2.4PCh. 8 - Prob. 8.2.5PCh. 8 - Prob. 8.2.6PCh. 8 - Prob. 8.2.7PCh. 8 - Prob. 8.2.8PCh. 8 - Prob. 8.2.9PCh. 8 - Prob. 8.2.10P

Ch. 8 - Prob. 8.2.11PCh. 8 - Prob. 8.2.12PCh. 8 - Prob. 8.2.13PCh. 8 - Prob. 8.3.1PCh. 8 - Prob. 8.3.2PCh. 8 - Prob. 8.3.3PCh. 8 - Prob. 8.3.4PCh. 8 - Prob. 8.3.5PCh. 8 - Prob. 8.3.6PCh. 8 - Prob. 8.3.7PCh. 8 - Prob. 8.3.8PCh. 8 - Prob. 8.3.9PCh. 8 - Prob. 8.3.10PCh. 8 - Use an elastic analysis and determine the maximum...Ch. 8 - Use an elastic analysis and determine the maximum...Ch. 8 - Use an elastic analysis and determine the maximum...Ch. 8 - Prob. 8.4.4PCh. 8 - Prob. 8.4.5PCh. 8 - Prob. 8.4.6PCh. 8 - Use an elastic analysis and compute the extra load...Ch. 8 - Use an elastic analysis and compute the extra load...Ch. 8 - Prob. 8.4.9PCh. 8 - Prob. 8.4.10PCh. 8 - Prob. 8.4.11PCh. 8 - Prob. 8.4.12PCh. 8 - Prob. 8.4.13PCh. 8 - Prob. 8.4.14PCh. 8 - Prob. 8.4.15PCh. 8 - Prob. 8.4.16PCh. 8 - Prob. 8.4.17PCh. 8 - Prob. 8.4.18PCh. 8 - a. Use LRFD and design a welded connection for the...Ch. 8 - Prob. 8.4.20PCh. 8 - Prob. 8.5.1PCh. 8 - Prob. 8.5.2PCh. 8 - Prob. 8.5.3PCh. 8 - Prob. 8.5.4PCh. 8 - Prob. 8.5.5PCh. 8 - Prob. 8.6.1PCh. 8 - Prob. 8.6.2PCh. 8 - Prob. 8.6.3PCh. 8 - Prob. 8.6.4PCh. 8 - Prob. 8.7.1PCh. 8 - Prob. 8.7.2PCh. 8 - Prob. 8.7.3PCh. 8 - Prob. 8.8.1PCh. 8 - Prob. 8.8.2PCh. 8 - Prob. 8.8.3PCh. 8 - Prob. 8.8.4P

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, civil-engineering and related others by exploring similar questions and additional content below.Similar questions

- The beam shown in the figure below is typical for a floor system in an existing building.It needs to carry a uniform live load of 260 lb/ft and a uniform dead weight of 400 lb/ft,including its own weight. The owner wants to add a partition weighing 7 kip (live load) asshown. Assuming the added partition as live load, is the beam section adequate to safelycarry the extra live load?PartitionStirrups15 ft 3 in.14 in.a. Determine the d e s i g n m o m e n t c a p a c i t y .b. D e t e r m i n e t h e f a c t o r e d a p p l i e d b e n d i n g m o m e n t .c. Is the beam safe and adequate for bending? Please explain your response.arrow_forward4. Use the influence function method to draw the influence line for the shear just to the right of A. Assume C is fixed, A is a roller, and B is a pin. 8 ft A 16 ft B 10 ft-arrow_forward4-39. Draw the shear and moment diagrams for each of the three members of the frame. Assume the frame is pin connected at A, C, and D and there is a fixed joint at B. 4 m 50 kN 40 kN -1.5 m -2 m 1.5 B 15 kN/m 6 m Darrow_forward

- Aggregates from three sources having the properties shown in Table P5.41were blended at a ratio of 25:60:15 by weight. Determine the properties of theaggregate blend.arrow_forward7-7. Determine the equations of the elastic curve for the beam using the x and x, coordinates. Specify the beam's maximum deflection. El is constant. 22arrow_forwardThe cantilever beam shown below supports a uniform service (unfactored) dead load of 1.5 kip/ft plus its own self weight, plus two unknown concentrated service (unfactored) live loads, as shown. The concrete has f’c = 6,000 psi and the steel yield strength is 60 ksi. a. Determine the design moment capacity. b. Set up the applied bending moment capacity. c. Calculate maximum safe concentrated live load that the beam may carry.arrow_forward

- The circular slab of radius r supported by four columns, as shown in figure, is to be isotropically reinforced. Find the ultimate resisting moment (m) per linear meter required just to sustain a concentrated factored load of P kN applied at the center of the slab. Solve by using equilibrium m m Columnarrow_forwardBy using the yield line theory, determine the ultimate resisting moment per linear meter (m) for an isotropic reinforced concrete two-way simply supported polygon slab shown in figure under a uniform load (q). Solve by using equilibrium method m marrow_forwardBy using the yield line theory, determine the ultimate resisting moment per linear meter (m) for an isotropic reinforced concrete two-way simply supported polygon slab shown in figure under a concentrated factored load of P. Solve by Using equilibrium method m m 8/arrow_forward

- H.W: Evaluate the integral 1. 30 √ · √(x²y – 2xy)dydx 0-2 3 1 3. (2x-4y)dydx 1-1 2π π 5. (sinx + cosy)dxdy π 0 0 1 ƒ ƒ (x + 2. +y+1)dxdy 4. -1-1 41 ][ 20 x²ydxdyarrow_forwardExample 5 By using the yield line theory, determine the moment (m) for an isotropic reinforced concrete two-way slab (supports on two S.S sides shown in figure under the load (P) (all dimensions are in mm). Solve by using equilibrium method Please solve by using equilibrium method m m 3000 2000 2000arrow_forward2. During construction, gate AB is temporarily held in place by the horizontal strut CD. Determine the force in the strut CD, if the gate is 3.0-m wide. A 0 B D Density of water = 103 kg/m³ 2 m 3 marrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Steel Design (Activate Learning with these NEW ti...Civil EngineeringISBN:9781337094740Author:Segui, William T.Publisher:Cengage Learning

Steel Design (Activate Learning with these NEW ti...Civil EngineeringISBN:9781337094740Author:Segui, William T.Publisher:Cengage Learning Architectural Drafting and Design (MindTap Course...Civil EngineeringISBN:9781285165738Author:Alan Jefferis, David A. Madsen, David P. MadsenPublisher:Cengage Learning

Architectural Drafting and Design (MindTap Course...Civil EngineeringISBN:9781285165738Author:Alan Jefferis, David A. Madsen, David P. MadsenPublisher:Cengage Learning

Steel Design (Activate Learning with these NEW ti...

Civil Engineering

ISBN:9781337094740

Author:Segui, William T.

Publisher:Cengage Learning

Architectural Drafting and Design (MindTap Course...

Civil Engineering

ISBN:9781285165738

Author:Alan Jefferis, David A. Madsen, David P. Madsen

Publisher:Cengage Learning

Uses of Aluminium | Environmental Chemistry | Chemistry | FuseSchool; Author: FuseSchool - Global Education;https://www.youtube.com/watch?v=lLWBE6w_oR4;License: Standard YouTube License, CC-BY