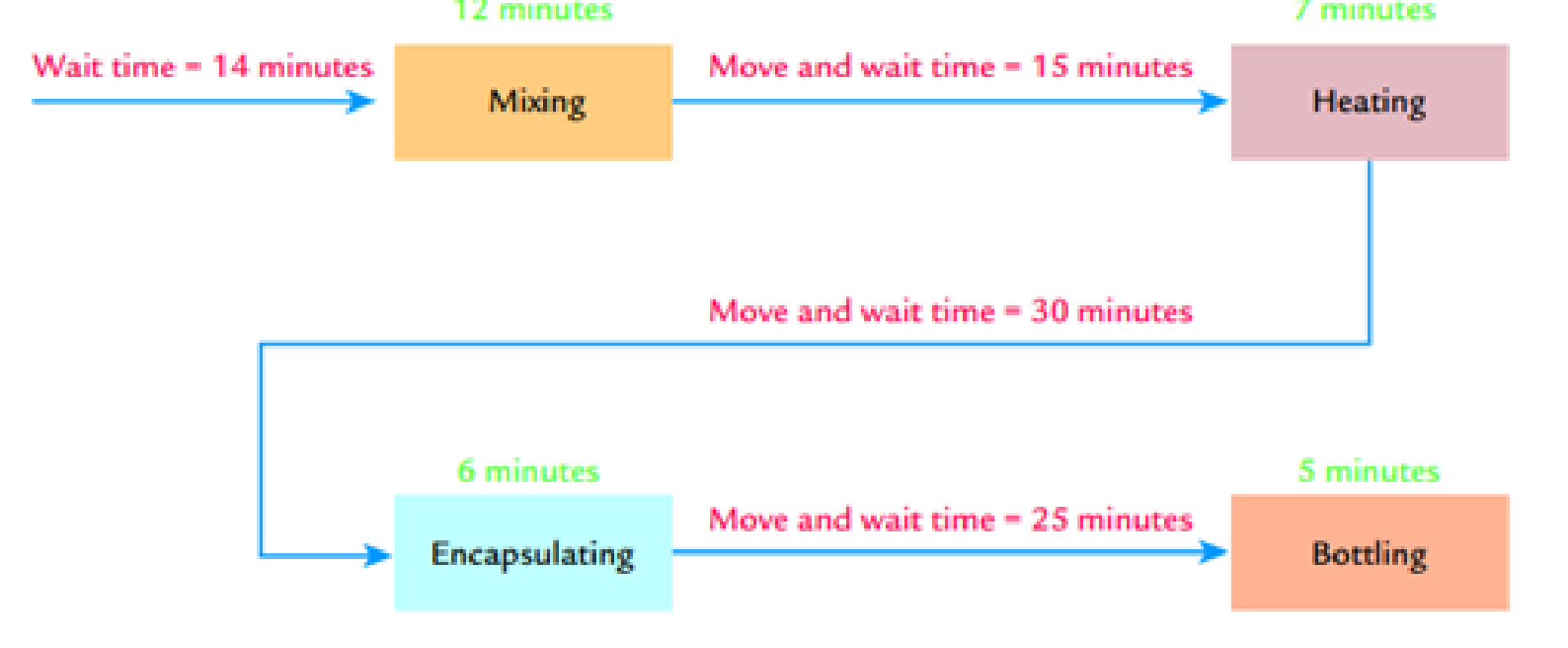

Erba Inc. has the following departmental layout for producing an herbal supplement:

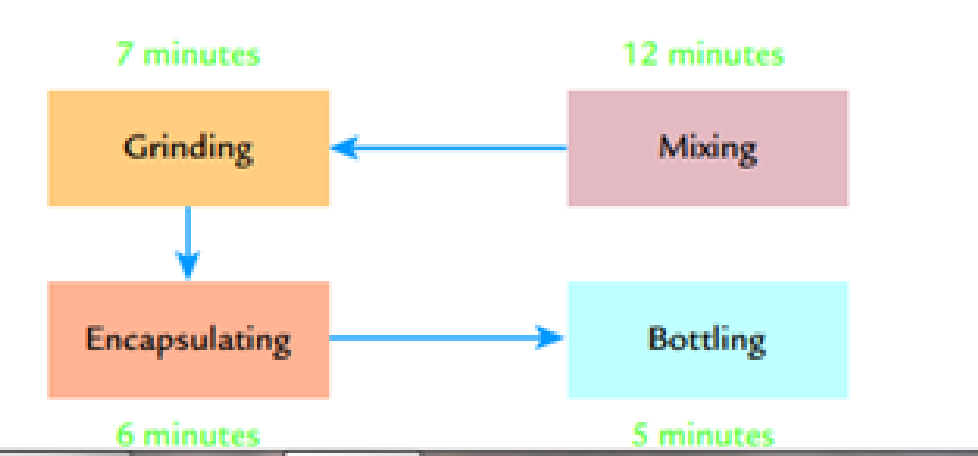

After a detailed study, the head of the plant’s industrial engineering department recommended that the following cellular manufacturing layout replace the current departmental structure:

Required:

- 1. Calculate the time required to produce a batch of 12 bottles using a batch processing departmental structure.

- 2. Calculate the time to process 12 units using cellular manufacturing.

- 3. How much manufacturing time will the cellular manufacturing structure save for a batch of 12 units?

- 4. How many units can the cell produce per hour, assuming the cell is producing on a continuous basis?

- 5. What must happen so that the cell can produce 12 units per hour, assuming the cell produces on a continuous basis?

1.

Compute the time taken to produce 12 units in case of a traditional manufacturing layout.

Answer to Problem 43E

Total time taken is 444 minutes.

Explanation of Solution

Traditional manufacturing layout:

In a traditional manufacturing layout, each process is undertaken within a separate department. In this layout large batches are processed, incurring significant wait time and move time.

Computation of time taken by 12 units:

| Particulars | Minutes |

| Wait time | 14 |

| Add: Time taken in mixing department | 144 |

| Add: Move and wait time between mixing and heating department | 15 |

| Add: Time taken in heating department | 84 |

| Add: Move and wait time between heating and encapsulating department | 30 |

| Add: Time taken in encapsulating department | 72 |

| Add: Move and wait time between encapsulating and bottling department | 25 |

| Add: Time taken in bottling department | 60 |

| Total time | 444 |

Table (1)

Therefore, total time taken is 444 minutes.

2.

Compute the time taken to produce 12 units in case of a cellular manufacturing layout.

Answer to Problem 43E

Total time taken to produce 12 units in cellular manufacturing is 162 minutes.

Explanation of Solution

Computation of time taken by 12 units:

| Particulars | Minutes |

|

Time taken by first unit | 30 |

|

Time taken by second unit | 42 |

|

Time taken by twelfth unit. | 162 |

| Total time | 162 |

Table (2)

Therefore, total time taken to produce 12 units in cellular manufacturing is 162 minutes.

3.

Compute the time saved in cellular manufacturing structure for a batch of 12 units.

Answer to Problem 43E

Time saved in cellular manufacturing structure for a batch of 12 units is 282 minutes.

Explanation of Solution

Computation of time saved in cellular manufacturing:

| Particulars | Minutes |

| Total time taken in traditional/batch processing | 444 |

| Total time taken in cellular processing | 162 |

| Time saved | 282 |

Table (3)

Therefore, time saved in cellular manufacturing structure for a batch of 12 units is 282 minutes.

4.

Compute the production rate in case of continuous operating.

Answer to Problem 43E

Production rate is 12 minutes per unit or 5 units per hour.

Explanation of Solution

There is a total of 12 minutes of waiting for each unit. In case, cell operates continuously and steadily, one unit would be produced after every 12 minutes. Therefore, it would take 144 minutes

Therefore, production rate is 12 minutes per unit or 5 units

5.

Explain the changes to be made so that the cell can produce 12 units per hour in case, cell produces on a continuous basis.

Answer to Problem 43E

Time taken by bottleneck activity should be 5 minutes.

Explanation of Solution

Computation of revised time taken by bottleneck activity:

Substitute 60 for minutes in an hour and 12 for the number of units required to be produced in the above formula.

The incremental time taken by each unit should be 5 minutes, in order to produce 12 units per hour on an incremental basis. For this, maximum time taken by any process should be 5 minutes.

Therefore, to produce 12 units per hour, time taken by bottleneck activity should be 5 minutes.

Want to see more full solutions like this?

Chapter 13 Solutions

Managerial Accounting: The Cornerstone of Business Decision-Making

- subject-general accountingarrow_forwardayco Inc. started its operations in 2022. Its sales during 2022, all on account, totalled $700,000. The company collected $500,000 in cash from customers during the year and wrote off $8,000 in uncollectible accounts. The company set up an allowance for doubtful accounts at December 31, 2022, its fiscal year-end, and determined the account balance to be $14,000. The unadjusted balances of selected accounts at December 31, 2023 are as follows: Accounts receivable $ 300,000 Allowance for doubtful accounts (debit) 10,000 Sales revenue (including 80 percent in sales on account) 800,000 Aging of the accounts receivable on December 31, 2023, resulted in an estimate of $11,000 in potentially uncollectible accounts. Required: 1. Prepare the journal entries to record all the transactions during 2022 and post them to appropriate T-accounts. (If no entry is required for a transaction/event, select "No journal entry required" in the first account field.)…arrow_forwardCalculate the sample size based on the specifications in Buhi's contract. Make sure it is within budget, reasonable to obtain, and that you use appropriate inputs relative to market research best practices. Use the calculator to adjust the sample size statement. Use the agreed-upon sample size in Buhi's contract: 996. In your secondary research, find the target population size (an estimate of those in the United States looking to purchase luggage in the category in the next two years). You will use this target population size for each sample size estimate. Adjust the provided sample size calculator inputs to find the rest of the figures that get you to the agreed-upon sample size. The caveats from Buhi are that you must: Use the market research standard for your confidence level. Use a confidence interval that is better than the market research standard for your confidence interval.arrow_forward

Managerial Accounting: The Cornerstone of Busines...AccountingISBN:9781337115773Author:Maryanne M. Mowen, Don R. Hansen, Dan L. HeitgerPublisher:Cengage Learning

Managerial Accounting: The Cornerstone of Busines...AccountingISBN:9781337115773Author:Maryanne M. Mowen, Don R. Hansen, Dan L. HeitgerPublisher:Cengage Learning Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning Essentials of Business Analytics (MindTap Course ...StatisticsISBN:9781305627734Author:Jeffrey D. Camm, James J. Cochran, Michael J. Fry, Jeffrey W. Ohlmann, David R. AndersonPublisher:Cengage Learning

Essentials of Business Analytics (MindTap Course ...StatisticsISBN:9781305627734Author:Jeffrey D. Camm, James J. Cochran, Michael J. Fry, Jeffrey W. Ohlmann, David R. AndersonPublisher:Cengage Learning