Manufacturing Engineering & Technology

7th Edition

ISBN: 9780133128741

Author: Serope Kalpakjian, Steven Schmid

Publisher: Prentice Hall

expand_more

expand_more

format_list_bulleted

Concept explainers

Textbook Question

Chapter 12, Problem 35SDP

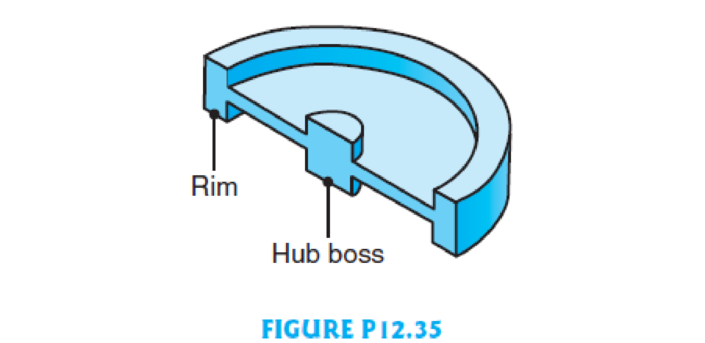

For the cast metal wheel illustrated in Fig. P12.35, show how (a) riser placement, (b) core placement, (c) padding, and (d) chills may be used to help feed molten metal and eliminate porosity in the isolated hub boss.

Expert Solution & Answer

Want to see the full answer?

Check out a sample textbook solution

Students have asked these similar questions

3

N2=28

P(diametral pitch)=8 for all gears

Coupled to 25 hp motor

N3=34

Full depth spur gears with pressure angle=20°

N₂=2000 rpm

(1) Compute the circular pitch, the center-to-center distance, and base circle radii.

(2) Draw the free body diagram of gear 3 and show all the forces and the torque.

(3) In mounting gears, the center-to-center distance was reduced by 0.1 inch.

Calculate the new values of center-to-center distance, pressure angle, base circle radii,

and pitch circle diameters.

(4)What is the new tangential and radial forces for gear 3?

(5) Under the new center to center distance, is the contact ratio (mc) increasing or

decreasing?

2. A flat belt drive consists of two 4-ft diameter cast-iron pulleys spaced 16 ft apart.

A power of 60 hp is transmitted by a pulley whose speed is 380 rev/min. Use a

service factor (Ks) pf 1.1 and a design factor 1.0. The width of the polyamide A-3

belt is 6 in. Use CD=1. Answer the following questions.

(1) What is the total length of the belt according to the given geometry?

(2) Find the centrifugal force (Fc) applied to the belt.

(3) What is the transmitted torque through the pulley system given 60hp?

(4) Using the allowable tension, find the force (F₁) on the tight side. What is the

tension at the loose side (F2) and the initial tension (F.)?

(5) Using the forces, estimate the developed friction coefficient (f)

(6) Based on the forces and the given rotational speed, rate the pulley set. In other

words, what is the horse power that can be transmitted by the pulley system?

(7) To reduce the applied tension on the tight side, the friction coefficient is

increased to 0.75. Find out the…

The tooth numbers for the gear train illustrated are N₂ = 24, N3 = 18, №4 = 30, №6 = 36, and

N₁ = 54. Gear 7 is fixed. If shaft b is turned through 5 revolutions, how many turns will shaft a make?

a

5

[6]

b

Chapter 12 Solutions

Manufacturing Engineering & Technology

Ch. 12 - Why are steels more difficult to cast than cast...Ch. 12 - What is the significance of hot spots in metal...Ch. 12 - What is shrinkage allowance? Machining allowance?Ch. 12 - Explain the reason for drafts in molds.Ch. 12 - Prob. 5RQCh. 12 - What are light castings and where are they used...Ch. 12 - Name the types of cast irons generally available,...Ch. 12 - Comment on your observations regarding Fig. 12.5.Ch. 12 - Describe the difference between a runner and a...Ch. 12 - What is the difference between machining allowance...

Ch. 12 - What is dross? Can it be eliminated?Ch. 12 - Describe your observation concerning the design...Ch. 12 - If you need only a few castings of the same...Ch. 12 - Do you generally agree with the cost ratings in...Ch. 12 - Describe the nature of the design differences...Ch. 12 - Note in Fig. 12.5 that the ductility of some cast...Ch. 12 - Do you think that there will be fewer defects in a...Ch. 12 - Explain the difference in the importance of drafts...Ch. 12 - What type of cast iron would be suitable for...Ch. 12 - Explain the advantages and limitations of sharp...Ch. 12 - Explain why the elastic modulus, E, of gray cast...Ch. 12 - If you were to incorporate lettering or numbers on...Ch. 12 - The general design recommendations for a well in...Ch. 12 - The heavy regions of parts typically are placed in...Ch. 12 - What are the benefits and drawbacks to having a...Ch. 12 - When designing patterns for casting, patternmakers...Ch. 12 - Using the information given in Table 12.2, develop...Ch. 12 - The part in Figure P12.28 is to be cast of 10% Sn...Ch. 12 - Describe the general design considerations...Ch. 12 - Add more examples of applications to those shown...Ch. 12 - Explain how ribs and serrations are helpful in...Ch. 12 - List casting processes that are suitable for...Ch. 12 - Small amounts of slag and dross often persist...Ch. 12 - If you need only a few units of a particular...Ch. 12 - For the cast metal wheel illustrated in Fig....Ch. 12 - Assume that the introduction to this chapter is...Ch. 12 - In Fig. P12.37, the original casting design shown...Ch. 12 - An incorrect and a correct design for casting are...Ch. 12 - Using the method of inscribed circles, shown in...Ch. 12 - A growing trend is the production of patterns and...Ch. 12 - Repeat Problem 12.40 for the case where (a) a...

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Please do not use any AI tools to solve this question. I need a fully manual, step-by-step solution with clear explanations, as if it were done by a human tutor. No AI-generated responses, please.arrow_forwardPlease do not use any AI tools to solve this question. I need a fully manual, step-by-step solution with clear explanations, as if it were done by a human tutor. No AI-generated responses, please.arrow_forwardCE-112 please solve this problem step by step and give me the correct answerarrow_forward

- CE-112 please solve this problem step by step and give me the correct asnwerarrow_forwardthis is an old practice exam, the answer is Ax = -4, Ay = -12,Az = 32.5, Bx= 34, Bz = 5, By = 0 but how?arrow_forwardThis is an old practice exam, the answer is Ax = Az = 0, Ay = 2000, TDE = 4750, Cx = 2000, Cy = 2000, Cz = -800 but how?arrow_forward

- this is an old practice exam, the answer is Fmin = 290.5lb but howarrow_forwardThis is an exam review question. The answer is Pmin = 622.9 lb but whyarrow_forwardPlease do not use any AI tools to solve this question. I need a fully manual, step-by-step solution with clear explanations, as if it were done by a human tutor. No AI-generated responses, please.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY

Casting Metal: the Basics; Author: Casting the Future;https://www.youtube.com/watch?v=2CIcvB72dmk;License: Standard youtube license