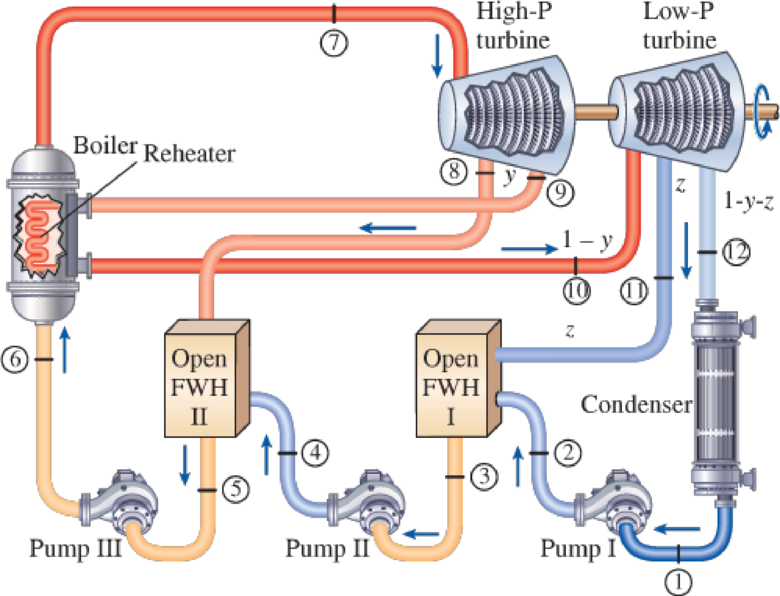

A steam power plant operates on an ideal reheat–regenerative Rankine cycle with one reheater and two open feedwater heaters. Steam enters the high-pressure turbine at 1500 psia and 1100°F and leaves the low- pressure turbine at 1 psia. Steam is extracted from the turbine at 250 and 40 psia, and it is reheated to 1000°F at a pressure of 140 psia. Water leaves both feedwater heaters as a saturated liquid. Heat is transferred to the steam in the boiler at a rate of 4 × 105 Btu/s. Show the cycle on a T-s diagram with respect to saturation lines, and determine (a) the mass flow rate of steam through the boiler, (b) the net power output of the plant, and (c) the thermal efficiency of the cycle.

FIGURE P10–62E

(a)

The mass flow rate of steam flowing through the boiler.

Answer to Problem 62P

The mass flow rate of steam flowing through the boiler is

Explanation of Solution

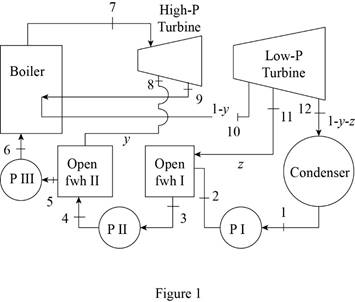

Draw the schematic layout of the given power plant that operates on an ideal reheat-regenerative Rankine cycle as shown in Figure 1.

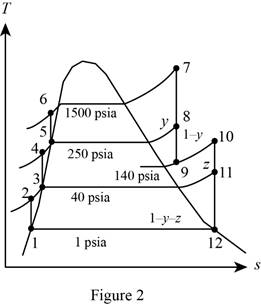

Draw the

Figure 2.

Here, water (steam) is the working fluid of the ideal regenerative Rankine cycle. The cycle involves three pumps.

Write the formula for work done by the pump during process 1-2.

Here, the specific volume is

Write the formula for enthalpy

Write the formula for work done by the pump during process 3-4.

Here, the specific volume is

Write the formula for enthalpy

Write the formula for work done by the pump during process 5-6.

Here, the specific volume is

Write the formula for enthalpy

Before reheating.

At state 9:

The steam expanded to the pressure of

After reheating.

At state 10:

The steam is reheated to the temperature of

At state 12:

The steam enters the condenser at the pressure of

The quality of water at state 12 is expressed as follows.

The enthalpy at state 12 is expressed as follows.

Here, the enthalpy is

Write the formula for heat in

Here, the mass fraction steam extracted from the turbine to the feed water entering the boiler via feed water heater-II

Write the general equation of energy balance equation.

Here, the rate of net energy inlet is

At steady state the rate of change of net energy of the system

Refer Equation (XI).

Write the energy balance equation for open feed water heater-II.

Rewrite the Equation (XII) in terms of mass fraction

Refer Equation (XI).

Write the energy balance equation for open feed water heater-I.

Rewrite the Equation (XIV) in terms of mass fraction

Write the formula for mass flow rate.

Here, the rate of heat input is

At state 1:

The water exits the condenser as a saturated liquid at the pressure of

Refer Table A-5E, “Saturated water-Pressure table”.

The enthalpy

At state 3: (Pump II inlet)

The water exits the open feed water heater-I as a saturated liquid at the pressure of

Refer Table A-5E, “Saturated water-Pressure table”.

The enthalpy

At state 5: (Pump III inlet)

The water exits the open feed water heater-II as a saturated liquid at the pressure of

Refer Table A-5E, “Saturated water-Pressure table”.

The enthalpy

At state 7: (H.P. Turbine inlet)

The steam enters the turbine as superheated vapor.

Refer Table A-6E, “Superheated water”.

The enthalpy

Refer Figure 2.

At state 8:

The steam is extracted at the pressure of

Refer Table A-6E, “Superheated water”.

The enthalpy

At state 9:

The steam is expanded at the pressure of

Refer Table A-6E, “Superheated water”.

The enthalpy

At state 10:

The steam is reheated to the temperature of

Refer Table A-6E, “Superheated water”.

The enthalpy

Refer Figure 2.

At state 11:

The steam is expanded at the pressure of

Refer Table A-6E, “Superheated water”.

The enthalpy

At state 12: (Condenser inlet)

The steam enters the condenser at the pressure of

Refer Table A-5E, “Saturated water-Pressure table”.

Obtain the following properties corresponding to the pressure of

Conclusion:

Substitute

Substitute

Substitute

Equation (III).

Substitute

Substitute

Equation (V).

Substitute

From Figure 2.

Substitute

Substitute

Equation (VIII).

Consider the open feed water heater-II alone.

Substitute

Equation (XIII).

Consider the open feed water heater-I alone.

Substitute

Substitute

Substitute

Substitute

Thus, the mass flow rate of steam flowing through the boiler is

(b)

The net power output of the plant.

Answer to Problem 62P

The net power output of the plant is

Explanation of Solution

Write the formula for net power output of the cycle per unit mass.

Write the formula for net power output of the cycle.

Here, the mass flow rate is

Conclusion:

Substitute

Substitute

Thus, the net power output of the plant is

(c)

The thermal efficiency of the cycle.

Answer to Problem 62P

The thermal efficiency of the cycle is

Explanation of Solution

Write the formula for thermal efficiency of the cycle

Conclusion:

Substitute

Thus, the thermal efficiency of the cycle is

Want to see more full solutions like this?

Chapter 10 Solutions

THERMODYNAMICS (LL)-W/ACCESS >CUSTOM<

Additional Engineering Textbook Solutions

Starting Out with Java: From Control Structures through Objects (7th Edition) (What's New in Computer Science)

Fluid Mechanics: Fundamentals and Applications

Java How to Program, Early Objects (11th Edition) (Deitel: How to Program)

Database Concepts (8th Edition)

Mechanics of Materials (10th Edition)

Starting Out With Visual Basic (8th Edition)

- I don't know how to solve thisarrow_forwardQuestion 2 (40 Points) Consider the following double pendulum-like system with links ₁ and 12. The angles 0 and & could have angular velocities ėêk and êk, respectively, where ②k is a unit vector that points out of the page and is perpendicular to x and y. They could also have angular accelerations Ök and êk. The angle is defined relative to the angle 0. The link 12 is a spring and can extend or compress at a rate of 12. It can also have a rate of extension or compression Ï2. li y êr1 êe 12 χ 3 еф er2 ده لج 1) Express the velocity of the mass in terms of the unit vectors ê0, êr1, êø, and êr2, and any extension/contraction of the links (e.g.,. i; and Ï¿) (12 Points) 2) Express the acceleration of the mass in terms of the unit vectors ê¤, ê×1, êp, and êÃ2, and any extension/contraction of the links (e.g.,. İ; and Ï¿) (12 Points) 3) Express the velocity of the mass in terms of unit vectors î and ĵ that point in the x and y directions, respectively. Also include the appropriate,…arrow_forwardprovide step by step solutions for angles teta 3 and teta 4 by the vector loopmethod. Show work in: vector loop, vector equations, solution procedure.arrow_forward

- (Manometer) A tank is constructed of a series of cylinders having diameters of 0.35, 0.30, and 0.20 m as shown in the figure below. The tank contains oil, water, and glycerin and a mercury manometer is attached to the bottom as illustrated. Calculate the manometer reading, h. 0.11 m + SAE 30 Oil 0.13 m + Water 0.10 m Glycerin + 0.10 m Mercury h = marrow_forwardP = A piston having a cross-sectional area of 0.40 m² is located in a cylinder containing water as shown in the figure below. An open U-tube manometer is connected to the cylinder as shown. For h₁ = 83 mm and h = 111 mm what is the value of the applied force, P, acting on the piston? The weight of the piston is negligible. Hi 5597.97 N P Piston Water Mercuryarrow_forwardStudent Name: Student Id: College of Applied Engineering Al-Muzahmiyah Branch Statics (AGE 1330) Section-1483 Quiz-2 Time: 20 minutes Date: 16/02/2025 Q.1. A swinging door that weighs w=400.0N is supported by hinges A and B so that the door can swing about a vertical' axis passing through the hinges (as shown in below figure). The door has a width of b=1.00m and the door slab has a uniform mass density. The hinges are placed symmetrically at the door's edge in such a way that the door's weight is evenly distributed between them. The hinges are separated by distance a=2.00m. Find the forces on the hinges when the door rests half-open. Draw Free body diagram also. [5 marks] [CLO 1.2] Mool b ర a 2.0 m B 1.0 marrow_forward

- For the walking-beam mechanism shown in Figure 3, find and plot the x and y coordinates of the position of the coupler point P for one complete revolution of the crank O2A. Use the coordinate system shown in Figure 3. Hint: Calculate them first with respect to the ground link 0204 and then transform them into the global XY coordinate system. y -1.75 Ꮎ Ꮎ 4 = 2.33 0242.22 L4 x AP = 3.06 L2 = 1.0 W2 31° B 03 L3 = 2.06 P 1 8 5 .06 6 7 P'arrow_forwardThe link lengths, gear ratio (2), phase angle (Ø), and the value of 02 for some geared five bar linkages are defined in Table 2. The linkage configuration and terminology are shown in Figure 2. For the rows assigned, find all possible solutions for angles 03 and 04 by the vector loop method. Show your work in details: vector loop, vector equations, solution procedure. Table 2 Row Link 1 Link 2 Link 3 Link 4 Link 5 λ Φ Ө a 6 1 7 9 4 2 30° 60° P y 4 YA B b R4 R3 YA A Gear ratio: a 02 d 05 r5 R5 R2 Phase angle: = 0₂-202 R1 05 02 r2 Figure 2. 04 Xarrow_forwardProblem 4 A .025 lb bullet C is fired at end B of the 15-lb slender bar AB. The bar is initially at rest, and the initial velocity of the bullet is 1500 ft/s as shown. Assuming that the bullet becomes embedded in the bar, find (a) the angular velocity @2 of the bar immediately after impact, and (b) the percentage loss of kinetic energy as a result of the impact. (c) After the impact, does the bar swing up 90° and reach the horizontal? If it does, what is its angular velocity at this point? Answers: (a). @2=1.6 rad/s; (b). 99.6% loss = (c). Ah2 0.212 ft. The bar does not reach horizontal. y X 4 ft 15 lb V₁ 1500 ft/s 0.025 lb C 30°7 B Aarrow_forward

- subject: combustion please include complete solution, no rounding off, with diagram/explanation etc. In a joule cycle, intake of the compressor is 40,000 cfm at 0.3 psig and 90 deg F. The compression ratio is 6.0 and the inlet temperature at the turbine portion is 1900R while at the exit, it is 15 psi. Calculate for the back work ratio in percent.arrow_forwardsubject: combustion please include complete solution, no rounding off, with diagram/explanation etc. A gasoline engine, utilizing cold air, recorded a work of 431 BTU/lb at a maximum temperature of 3,273 K and 1112 deg F temperature at the beginning of constant volume heat addition. What is the compression ratio?arrow_forwardsubject: combustion please do step by step solution and no rounding off, complete solution with diagram/explanation if needed etc. thank you! Air enters the compressor at 101,320 Pascals, 305.15K, and leaves at a pressure of 0.808MPa. The air is heated to 990.15K in the combustion chamber. For a net output of 2,125,000 Watts, find the rate of flow of air per second.arrow_forward

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY