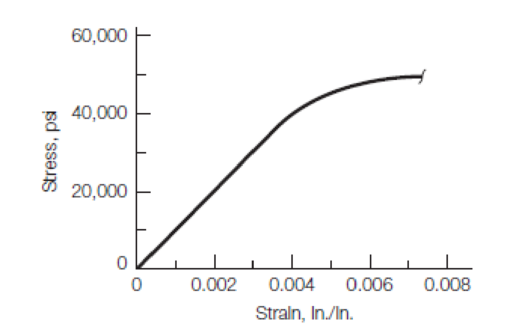

The stress–strain relationship shown in Figure P1.16 was obtained during the tensile test of an aluminum alloy specimen.

Determine the following:

a. Young’s modulus within the linear portion

b. Tangent modulus at a stress of 45,000 psi

c. Yield stress using an offset of 0.002 strain

d. If the yield stress in part c is considered failure stress, what is the maximum working stress to be applied to this material if a factor of safety of 1.5 is used?

Learn your wayIncludes step-by-step video

Chapter 1 Solutions

Materials for Civil and Construction Engineers (4th Edition)

Additional Engineering Textbook Solutions

Mechanics of Materials (10th Edition)

Electric Circuits. (11th Edition)

Elementary Surveying: An Introduction To Geomatics (15th Edition)

Starting Out with Java: From Control Structures through Data Structures (4th Edition) (What's New in Computer Science)

Starting Out with Python (4th Edition)

Starting Out With Visual Basic (8th Edition)

- The floor system of a gymnasium consists of a 130-mm-thick concrete slab resting on four steel beams (A = 9100 mm²) that, in turn, are supported by two steel girders (A = 25600 mm²), as shown in Fig. 2.3. Determine the dead loads acting on beam BF and girder AD. 2.3 Beam BF Uniformly distributed load ㅋㅋ =28.6 (5) (180) + 77 (100) = 16.04 kN/m 16.04 kN/m B 80.2 kN F 80.2 kN.arrow_forwardTrucks begin to arrive at a truck weigh station (with a single scale) at 6:00 A.M. at a deterministic but time-varying rate of λ(t) = 4.3 − 0.22t [λ(t) is in veh/min and t is in minutes]. The departure rate is a constant 2 veh/min (time to weigh a truck is 30 seconds). When will the queue that forms be cleared, what will be the total delay, and what will be the maximum queue length?arrow_forwardhow many custom bricks of size 3 1/4 x 3 3/4arrow_forward

- How many custom bricks of size 3 1/4 x 3 3/4 x 11 7/8 inches are there per square foot of wall area when the mortar joint is 1/4arrow_forwardGiven a circular curve connecting 2 tangents that intersect at an angle of 55°. The PI is at thestation (948+50) and the design speed of the highway is 70 mi/h. Determine:(a) stations of the PC and PT(c) Deflection angles and chord lengths for the first, middle, and last chordsarrow_forwardA simple circular curve exists with a radius of 900 ft connects the tangents of a two-lanehighway that has a posted speed limit of 45 mph. The highway curve is not superelevated,e=0. A structure is proposed on land on the inside of the curve. Assume the road is on a levelgrade. Determine the minimum distance allowable between the proposed structure and thecenterline of the curve such that the current maximum safe speed of the curve would notneed to be reducedarrow_forward

- A +4.4% grade intersects with a -3.3% grade at a station (550+30) at an elevation of400 ft. If the design speed is 60 mi/h, determine:(a) the minimum length of the vertical curve using the rate of vertical curvature(b) the stations and elevations of the BVC and EVC(c) the tangent and curve elevations of BVC, full stations, and EVC(d) the station and elevation of the highest pointarrow_forwardDetermine the minimum length of a sag vertical curve if the grades are –3% and +4%. The design speed is 75 mi/h. State all assumptions used. Make sure to consider the following criteria: stopping sight distance, comfort, and general appearancearrow_forwardQuestion 6: Chlorine is widely used to purify municipal water supplies and to treat swimming pool waters. Suppose that the volume of a particular sample of Cl₂ gas is 8.70 L at 895 torr and 24°C. (a) How many grams of Cl₂ are in the sample? ⚫ Atomic mass of CI = 35.453 g/mol • Molar mass of Cl₂ = 2 x 35.453 = 70.906 g/mol Solution: Use the Ideal Gas Law: Step 1: Convert Given Values • Pressure: P = 895 torr → atm PV= = nRT 1 P = 895 × = 1.1789 atm 760 • Temperature: Convert to Kelvin: T24273.15 = 297.15 K • Gas constant: R = 0.0821 L atm/mol. K Volume: V = 8.70 L Step 2: Solve for n . PV n = RT n = (1.1789)(8.70) (0.0821)(297.15) 10.25 n = = 0.420 mol 24.405 Step 3: Calculate Mass of Cl₂ Final Answer: 29.78 g of Cl₂. mass nx M mass= (0.420)(70.906) mass= 29.78 garrow_forward

- Please solve the highlighted question.arrow_forward1. Design a PVC sanitary sewer collection system for the Village of Waffle (Figure P-17-24 B, shown below) by preparing a sewer design table similar to that shown in Example 19-2 and a profile drawing similar to Figure 19-13b B. You only need to show the calculations for the pipes running along Bacon Road and Eggs Road, starting at point F and ending at Point B in the figure below. Your design should comply with the requirements specified in Chapter 30 of the 10 States Standards for Wastewater. Use the following assumptions: 0 о о Average daily flow rate is the same as average daily water demand, 9.2 m³/hr Peaking factor for peak dry weather flow is 6.2 Peak wet weather flow is equal to the peak dry weather flow plus an assumption for infiltration and inflow at 40 L/d-mm-km of pipe DODO on Ro 450 m 28 m D. 150 m Apartments D 400 m D 200 m B 250 m 0 Dogs Road ROOD625 m -120 m Syrup River 120 m 100-Year flood Point Elevation Tank 137.0 m A 130.0 m B 122.0 m C 122.3 m D 122.6 m A D 300 m…arrow_forwardNeed helparrow_forward

Materials Science And Engineering PropertiesCivil EngineeringISBN:9781111988609Author:Charles GilmorePublisher:Cengage Learning

Materials Science And Engineering PropertiesCivil EngineeringISBN:9781111988609Author:Charles GilmorePublisher:Cengage Learning Steel Design (Activate Learning with these NEW ti...Civil EngineeringISBN:9781337094740Author:Segui, William T.Publisher:Cengage Learning

Steel Design (Activate Learning with these NEW ti...Civil EngineeringISBN:9781337094740Author:Segui, William T.Publisher:Cengage Learning Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781337705028Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning

Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781337705028Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning