Fox And Mcdonald's Introduction To Fluid Mechanics

9th Edition

ISBN: 9781118921876

Author: Pritchard, Philip J.; Leylegian, John C.; Bhaskaran, Rajesh

Publisher: WILEY

expand_more

expand_more

format_list_bulleted

Concept explainers

Textbook Question

Chapter 8, Problem 117P

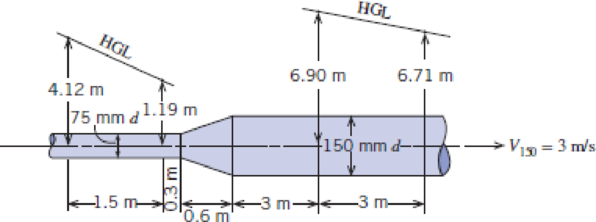

Experimental determination of local losses and loss coefficients are made from measurements of the hydraulic grade lines in zones of established flow. Calculate the head loss and loss coeffecients for this gradual expansion from the data given.

P8.117

Expert Solution & Answer

Want to see the full answer?

Check out a sample textbook solution

Students have asked these similar questions

subject: combustion

please include complete solution, no rounding off, with diagram/explanation etc.

In a joule cycle, intake of the compressor is 40,000 cfm at 0.3 psig and 90 deg F. The compression ratio is 6.0 and the inlet temperature at the turbine portion is 1900R while at the exit, it is 15 psi. Calculate for the back work ratio in percent.

subject: combustion

please include complete solution, no rounding off, with diagram/explanation etc.

A gasoline engine, utilizing cold air, recorded a work of 431 BTU/lb at a maximum temperature of 3,273 K and 1112 deg F temperature at the beginning of constant volume heat addition. What is the compression ratio?

subject: combustion

please do step by step solution and no rounding off, complete solution with diagram/explanation if needed etc. thank you!

Air enters the compressor at 101,320 Pascals, 305.15K, and leaves at a pressure of 0.808MPa. The air is heated to 990.15K in the combustion chamber. For a net output of 2,125,000 Watts, find the rate of flow of air per second.

Chapter 8 Solutions

Fox And Mcdonald's Introduction To Fluid Mechanics

Ch. 8 - Consider incompressible flow in a circular...Ch. 8 - What is the maximum flow rate of air that may...Ch. 8 - For flow in circular tubes, transition to...Ch. 8 - An incompressible fluid flows between two infinite...Ch. 8 - Oil is confined in a 4-in.-diameter cylinder by a...Ch. 8 - Viscous oil flows steadily between parallel...Ch. 8 - Calculate for the flow in this two-dimensional...Ch. 8 - The velocity profile in a two-dimensional open...Ch. 8 - A large mass is supported by a piston of diameter...Ch. 8 - A hydraulic jack supports a load of 9000 kg. The...

Ch. 8 - The basic component of a pressure gage tester...Ch. 8 - When a horizontal laminar flow occurs between two...Ch. 8 - In a laminar flow of water of 0:007 m3/s between...Ch. 8 - Consider the simple power-law model for a...Ch. 8 - A sealed journal bearing is formed from concentric...Ch. 8 - Using the profile of Problem 8.15, show that the...Ch. 8 - In a laminar flow between parallel plates spaced...Ch. 8 - A fluid of specific gravity 0.90 flows at a...Ch. 8 - Two immiscible fluids are contained between...Ch. 8 - The record-read head for a computer disk-drive...Ch. 8 - Consider steady, incompressible, and fully...Ch. 8 - In a flow of air between parallel plates spaced...Ch. 8 - Consider fully developed flow between parallel...Ch. 8 - Free-surface waves begin to form on a laminar...Ch. 8 - A viscous-shear pump is made from a stationary...Ch. 8 - The efficiency of the viscous-shear pump of Fig....Ch. 8 - An inventor proposes to make a viscous timer by...Ch. 8 - A continuous belt, passing upward through a...Ch. 8 - A wet paint film of uniform thickness, , is...Ch. 8 - Consider first water and then SAE 10W lubricating...Ch. 8 - Using Eq. A.3 in Appendix A for the viscosity of...Ch. 8 - Consider fully developed laminar flow in the...Ch. 8 - Carbon dioxide flows in a 50-mm-diameter pipe at a...Ch. 8 - Consider fully developed laminar flow in a...Ch. 8 - What is the largest diameter of pipeline that may...Ch. 8 - Consider fully developed laminar flow in the...Ch. 8 - Consider fully developed pressure-driven flow in a...Ch. 8 - In the laminar flow of an oil of viscosity 1 Pa_s,...Ch. 8 - In a laminar flow of 0.007 m3/s in a...Ch. 8 - Consider blood flow in an artery. Blood is...Ch. 8 - The classic Poiseuille flow (Eq. 8.12), is for...Ch. 8 - For pressure-driven, steady, fully developed...Ch. 8 - In a laminar flow in a 12-in.-diameter pipe the...Ch. 8 - A fluid of specific gravity 0.90 flows at a...Ch. 8 - In a food industry plant, two immiscible fluids...Ch. 8 - A horizontal pipe carries fluid in fully developed...Ch. 8 - Kerosene is pumped through a smooth tube with...Ch. 8 - In a flow of water in a 0.3-m-diameter pipe, the...Ch. 8 - A liquid drug, with the viscosity and density of...Ch. 8 - Laufer [5] measured the following data for mean...Ch. 8 - Equation 8.23 gives the power-law velocity profile...Ch. 8 - Consider fully developed laminar flow of water...Ch. 8 - Consider fully developed laminar flow in a...Ch. 8 - If the turbulent velocity profile in a pipe 0.6 m...Ch. 8 - Water flows in a horizontal constant-area pipe;...Ch. 8 - For a given volume flow rate and piping system,...Ch. 8 - Consider the pipe flow from the water tower of...Ch. 8 - At the inlet to a constant-diameter section of the...Ch. 8 - When oil (kinematic viscosity 1 104 m2/s,...Ch. 8 - When fluid of specific weight 50 lb/ft3 flows in a...Ch. 8 - If the head lost in 30-m-diameter of...Ch. 8 - Water flows at 10 L/min through a horizontal...Ch. 8 - Laufer [5] measured the following data for mean...Ch. 8 - Water is pumped at the rate of 0.075 m3/s from a...Ch. 8 - Just downstream from the nozzle tip the velocity...Ch. 8 - A horizontal nozzle having a cylindrical tip of 75...Ch. 8 - When 0.3 m3/s of water flows through a...Ch. 8 - Water flows through a 2-in.-diameter tube that...Ch. 8 - A 50-mm-diameter nozzle terminates a vertical...Ch. 8 - A 12-in.-diameter pipe leaves a reservoir of...Ch. 8 - A water pipe gradually changes from 6-in.-diameter...Ch. 8 - Air at standard conditions flows through a sudden...Ch. 8 - Water flows from a larger pipe, diameter D1 = 100...Ch. 8 - Flow through a sudden contraction is shown. The...Ch. 8 - A flow rate of 1.01/min of oil of specific gravity...Ch. 8 - Water flows in a smooth pipeline at a Reynolds...Ch. 8 - Air flows out of a clean room test chamber through...Ch. 8 - A conical diffuser is used to expand a pipe flow...Ch. 8 - By applying the basic equations to a control...Ch. 8 - Water at 45C enters a shower head through a...Ch. 8 - Water discharges to atmosphere from a large...Ch. 8 - A laboratory experiment is set up to measure...Ch. 8 - Oil with kinematic viscosity = 7.5 104 ft2/s...Ch. 8 - Water from a pump flows through a 9-in.-diameter...Ch. 8 - A 5-cm-diameter potable water line is to be run...Ch. 8 - A system for testing variable-output pumps...Ch. 8 - Two reservoirs are connected by three clean...Ch. 8 - Water, at volume flow rate Q = 0.75 ft3/s, is...Ch. 8 - When you drink a beverage with a straw, you need...Ch. 8 - What flow rate (gpm) will be produced in a...Ch. 8 - Gasoline flows in a long, underground pipeline at...Ch. 8 - An 18-in.-diameter new riveted steel pipeline 1000...Ch. 8 - What diameter of smooth masonry pipe is needed to...Ch. 8 - Water flows steadily in a 125-mm-diameter...Ch. 8 - Two galvanized iron pipes of diameter D are...Ch. 8 - A mining engineer plans to do hydraulic mining...Ch. 8 - The flow of water through a 150-mm-diameter...Ch. 8 - The fluid flowing has specific gravity 0.90; V75=6...Ch. 8 - Water is flowing. Calculate the direction and...Ch. 8 - Investigate the effect of tube roughness on flow...Ch. 8 - Investigate the effect of tube length on water...Ch. 8 - For the pipe flow into a reservoir of Example 8.5...Ch. 8 - Calculate the magnitude and direction of the...Ch. 8 - Experimental determination of local losses and...Ch. 8 - Water is flowing. Calculate the gage reading when...Ch. 8 - The siphon shown is fabricated from 50-mm-i.d....Ch. 8 - A large open water tank has a horizontal cast iron...Ch. 8 - A tank containing 30 m3 of kerosene is to be...Ch. 8 - A 90 screwed elbow is installed in a...Ch. 8 - Calculate the total tension in the bolts. Neglect...Ch. 8 - A horizontal 50-mm-diameter PVC pipeline leaves...Ch. 8 - You are watering your lawn with an old hose....Ch. 8 - Your boss claims that for pipe flow the flow rate,...Ch. 8 - A hydraulic press is powered by a remote...Ch. 8 - One-quarter of a cubic meter per second of liquid...Ch. 8 - Calculate the flow rate from this water tank if...Ch. 8 - A 6-ft-diameter pipeline 4 miles long between two...Ch. 8 - A new industrial plant requires a water flow rate...Ch. 8 - What diameter water pipe is required to handle...Ch. 8 - A pipe friction experiment for air consists of a...Ch. 8 - Oil has been flowing from a large tank on a hill...Ch. 8 - The pressure rise across a water pump is 35 psi...Ch. 8 - Cooling water is pumped from a reservoir to rock...Ch. 8 - You are asked to size a pump for installation in...Ch. 8 - Heavy crude oil (SG = 0.925 and = 1.0 104 m2/s)...Ch. 8 - Petroleum products are transported over long...Ch. 8 - The head versus capacity curve for a certain fan...Ch. 8 - A swimming pool has a partial-flow filtration...Ch. 8 - Water at 65C flows through a 75-mm-diameter...Ch. 8 - A 12 in. 6 in. Venturi meter is installed in a...Ch. 8 - A 1-in.-diameter nozzle is attached to a...Ch. 8 - A sharp-edged orifice with conventional pressure...Ch. 8 - A venturi meter with a 3-in.-diameter throat is...Ch. 8 - Air flows through a venturi meter with a...Ch. 8 - Water at 10C flows steadily through a venturi. The...Ch. 8 - Drinking straws are to be used to improve the air...Ch. 8 - In some western states, water for mining and...

Additional Engineering Textbook Solutions

Find more solutions based on key concepts

Write an SQL query to list each customer who bought at least one product that belongs to product line Basic in ...

Modern Database Management

1‘21 Same as Problem 1.20, excepi the anicle should be

on safety as related to su rveying-

Elementary Surveying: An Introduction To Geomatics (15th Edition)

Write a sequence of instructions (using the operations SELECT, PROJECT, and JOIN) to retrieve the Name and JobT...

Computer Science: An Overview (13th Edition) (What's New in Computer Science)

Give the declaration for two variables of type double. The variables are to be named rate and time. Both variab...

Java: An Introduction to Problem Solving and Programming (8th Edition)

17–1C A high-speed aircraft is cruising in still air. How does the temperature of air at the nose of the aircra...

Thermodynamics: An Engineering Approach

For the circuit shown, find (a) the voltage υ, (b) the power delivered to the circuit by the current source, an...

Electric Circuits. (11th Edition)

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- The link lengths and the value of 2 and offset for some fourbar crank-slide linkages are defined in Table 1. The linkage configuration and terminology are shown in Figure 1. For the rows assigned, find (a) all possible solutions for angle & and slider position d by vector loop method. (b) the transmission angle corresponding to angle 03. (Hint: Treat the vector R4 as virtual rocker) Show your work in details: vector loop, vector equations, solution procedure. Table 1 Row Link 2 Link 3 Offset Ө a 1.4 4 1 45° b 3 8 2 -30° C 5 20 -5 225° 03 slider axis B X offset Link 2 A R3 Link 3 R4 04 R2 02 R1 d Figure 1. Xarrow_forward4. Two links made of heat treated 6061 aluminum (Sy = 276 MPa, Sys = 160 MPa) are pinned together using a steel dowel pin (Sy = 1398 MPa, Sys = 806 MPa) as shown below. The links are to support a load P with a factor of safety of at least 2.0. Determine if the link will fail first by tearout, direct shear of the pin, bearing stress on the link, or tensile stress at section AA. (Hint: find the load P for each case and choose the case that gives the smallest load.) P 8 mm P 8 mm ¡+A 3 mm →A 10 mm Parrow_forward1. For a feature other than a sphere, circularity is where: A. The axis is a straight line B. The modifier is specified with a size dimension C. All points of the surface intersected by any plane perpendicular to an axis or spine (curved line) are equidistant from that axis or spine D. All points of the surface intersected by any plane passing through a common center are equidistant from that center 2. What type of variation is limited by a circularity toler- ance zone? A. Ovality B. Tapering C. Bending D. Warping 3. How does the Rule #1 boundary affect the application of a circularity tolerance? A. The modifier must be used. B. The feature control frame must be placed next to the size dimension. C. The circularity tolerance value must be less than the limits of size tolerance. D. Circularity cannot be applied where a Rule #1 boundary exists. 4. A circularity tolerance may use a modifier. A. Ø B. F C. M D. ℗ 5. A real-world application for a circularity tolerance is: A. Assembly (i.e.,…arrow_forward

- 3. A steel bar is pinned to a vertical support column by a 10 mm diameter hardened dowel pin, Figure 1. For P = 7500 N, find: a. the shear stress in the pin, b. the direct bearing stress on the hole in the bar, c. the minimum value of d to prevent tearout failure if the steel bar has a shear strength of 175 MPa. support column pin bar thickness of bar = 8 mm h d 150 mmarrow_forwardA press that delivers 115 strokes per minute, each stroke providing a force of 7826 N throughout a distance of 18 mm. The press efficiency is 90% and is driven by a 1749-rpm motor. Determine average torque that must be provided by the motor in the units of N-m.arrow_forward·3) find the force (P) for the figures (1) and (2) 15cm 10cm 15 h=10mm h2=6mm // Call = 90 N/2 P Agate Fig (i) Ans: 1)P=112614N 2) P=1956.5 N 25cm 25 cm الفترة أو الحجم تمر بالتي عثر اكو تورشن (ک Fig (2) h₁ = 10mm 42=6mm Cmarrow_forward

- 3. A steam power plant has an average monthly net power delivery of 740 MW over the course of a year. This power delivery is accomplished by burning coal in the boiler. The coal has a heating value of 9150 Btu/lbm. The cost of the coal is $14.20/ton. The overall thermal efficiency of the plant is, nth = Wnet Qboiler = 0.26 = 26% Determine the annual cost of the coal required to deliver the given average monthly power.arrow_forward47 14 16 12 34 10 12 12 33arrow_forward= The forces F₁ = 590 lb, F₂ = 380 lb, F3 = 240 lb and F 330 lb. Determine the forces in each member of the truss. Use positive values to indicate tension and negative values to indicate compression. a a a D b F₁ A 000 B. 779977 F₂V H G E F4 b BY NC SA 2013 Michael Swanbom Values for dimensions on the figure are given in the following table. Note the figure may not be to scale. Variable Value a 6 ft b 10.1 ft The force in member AB is lb. The force in member AH is lb. The force in member GH is lb. The force in member BH is lb. The force in member BC is lb. The force in member BG is lb. The force in member EG is lb. The force in member CD is lb. The force in member DE is lb. The force in member CE is lb. The force in member CG is lb.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY

8.01x - Lect 27 - Fluid Mechanics, Hydrostatics, Pascal's Principle, Atmosph. Pressure; Author: Lectures by Walter Lewin. They will make you ♥ Physics.;https://www.youtube.com/watch?v=O_HQklhIlwQ;License: Standard YouTube License, CC-BY

Dynamics of Fluid Flow - Introduction; Author: Tutorials Point (India) Ltd.;https://www.youtube.com/watch?v=djx9jlkYAt4;License: Standard Youtube License