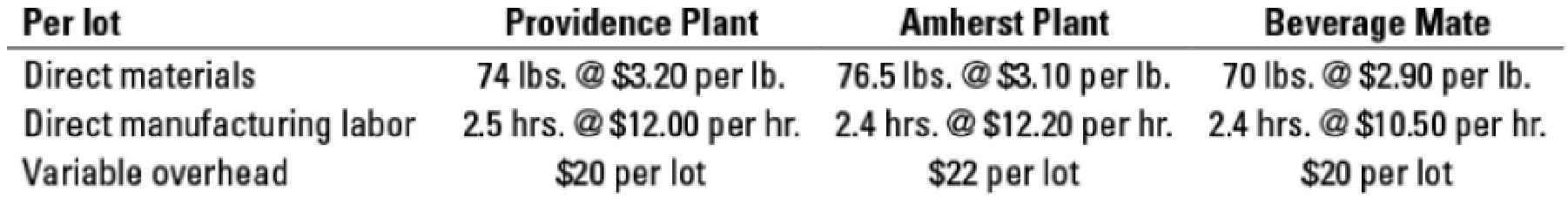

Price and efficiency variances, benchmarking. Nantucket Enterprises manufactures insulated cold beverage cups printed with college and corporate logos, which it distributes nationally in lots of 12 dozen cups. In June 2017, Nantucket produced 5,000 lots of its most popular line of cups, the 24-ounce lidded tumbler, at each of its two plants, which are located in Providence and Amherst. The production manager, Shannon Bryant, asks her assistant, Joel Hudson, to find out the precise per-unit budgeted variable costs at the two plants and the variable costs of a competitor, Beverage Mate, who offers similar-quality tumblers at cheaper prices. Hudson pulls together the following information for each lot:

- 1. What is the budgeted variable cost per lot at the Providence Plant, the Amherst Plant, and at Beverage Mate?

Required

- 2. Using the Beverage Mate data as the standard, calculate the direct materials and direct manufacturing labor price and efficiency variances for the Providence and Amherst plants.

- 3. What advantage does Nantucket get by using Beverage Mate’s benchmark data as standards in calculating its variances? Identify two issues that Bryant should keep in mind in using the Beverage Mate data as the standards.

Want to see the full answer?

Check out a sample textbook solution

Chapter 7 Solutions

Horngren's Cost Accounting: A Managerial Emphasis (16th Edition)

- General Accountarrow_forwardGeneral Accounting provide correct solutionarrow_forward3 Red Oil Corp. has two divisions, Refining and Production. The company's primary product is Clean Oil. Each division's costs are provided below: Refining: Variable costs per litre of oil $30 Fixed costs per litre of oil $24 Production: Variable costs per litre of oil $6 Fixed costs per litre of oil $4 The Production Division is able to sell the oil to other areas for $24 per litre. The Refining Division has been operating at a capacity of 80,000 litres a day, using oil from the Production Division and oil purchased from other suppliers. The Refining Division usually purchases 50,000 litres of oil, on average, from the Production Division and 30,000 litres, on average, from other suppliers at $40/litre. What is the Production Division's operating income per 200 litres of oil reported under the 175% of variable costs method? Select one: a. $1,500 b. $100 c. $1,200 d. $(100) e. $880arrow_forward

- During the past year Badger Company had a net income of $175,000. What is the ROI if the investment is $25,000? Select one: a. 5.450 b. 2.500 c. 0.142 d. 7.000 e. 5.140arrow_forward15 Green Thumb Rentals Ltd. incurred $60,000 of common fixed costs and $90,000 of common variable costs. Data are provided below for the capacity allowed and the capacity used. Department Capacity Available in Hours Capacity Used in Hours Tools Department 3,600 3,200 Equipment Department 1,800 1,800 For both departments, common fixed costs are to be allocated on the basis of capacity available and common variable costs are to be allocated on the basis of capacity used. The fixed and variable costs allocated to the Tools Department are Select one: a. $31,756 and $45,000, respectively b. $60,000 and $90,000, respectively c. $20,000 and $32,400, respectively d. $30,000 and $45,000 respectively e. $40,000 and $57,600, respectivelyarrow_forward25. What purpose does structural dependency analysis serve? a) Independent treatment works better b) Business relationship impacts guide reporting choices c) Dependencies add confusion d) Standard methods sufficearrow_forward

- Need help with this question solution general accountingarrow_forwardBata Company's salaried employees are paid biweekly. Occasionally, advances made to employees are paid back by payroll deductions. Information relating to salaries for the calendar year 2022 is as follows: Employee advances Accrued salaries payable Salaries expense during the year Salaries paid during the year (gross) 12/31/21 12/31/22 $12,000 $ 18,000 75,000 ? 650,000 625,000 At December 31, 2022, what amount should Bata report for accrued salaries payable?arrow_forwardPlease given correct option general accountingarrow_forward

- Question: Cost Account Beginning inventory Units produced Units sold 5000 20,000 23,700 Cost per unit: Direct materials $ 8.00 Direct labor $4.00 Variable overhead Fixed overhead Variable selling exp. $ 1.50 $4.15 $ 3.00 Fixed selling and admin. exp. $ 24,000 Fixed overhead totals $83,000 per year. Assume the selling price is $27 per unit. 1. Calculate operating income using absorption costing. 2. Calculate operating income using variable costing.arrow_forward8 The cost of visiting customers would MOST likely be classified as a Select one: a. Corporate-sustaining cost. b. Customer-sustaining cost. c. Distribution-channel cost d. Customer batch-level cost. e. Customer output unit-level cost.arrow_forwardFinancial Accounting Question please find correct answerarrow_forward

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning