Concept explainers

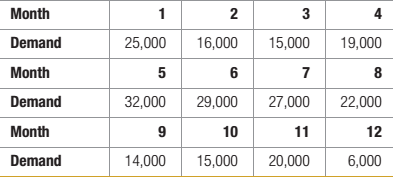

Climate Control, Inc. makes expedition-quality rain gear for outdoor enthusiasts. Management prepared a

Use the Sales and Operations Planning with Spread sheets Solver in OM Explorer or develop your own spreadsheet models to address the following questions.

- Management is willing to authorize overtime in periods for which regular production and current levels of anticipation inventory do not satisfy demand. However, overtime must be strictly limited to no more than 20 percent of regular-time capacity. Management wants to avoid stockouts and backorders and is not willing to accept a plan that calls for shortages. Is it feasible to hold the workforce constant, assuming that overtime is only used in periods for which shortages would occur?

- Assume that management is not willing to authorize any overtime. Instead, management is will to negotiate with customers so that backorders may be used as a supply option. However, management is not willing to carry more than 5,000 suits from one month to the next in backorder. Is it feasible to hold the work-force constant, assuming that a maximum backorder of 5,000 suits may be maintained from month to month?

- Assume management is willing to authorize the use of overtime over the next 4 months to build additional anticipation inventory. However, overtime must be strictly limited to no more than 20 percent of regular-time capacity. Management wants to avoid stockouts and backorders and is not willing to accept a plan that calls for shortages. Is it feasible to hold the workforce constant, assuming that overtime is only used in months 1 through 4? If not, in which months would additional overtime be required?

Want to see the full answer?

Check out a sample textbook solution

Chapter 10 Solutions

Operations Management: Processes and Supply Chains (11th Edition)

Additional Business Textbook Solutions

Business Essentials (12th Edition) (What's New in Intro to Business)

Marketing: An Introduction (13th Edition)

Foundations Of Finance

Horngren's Accounting (12th Edition)

Horngren's Cost Accounting: A Managerial Emphasis (16th Edition)

Principles of Operations Management: Sustainability and Supply Chain Management (10th Edition)

- What are the responsibilities and duties of a consultant for a local company who is considering expanding its operations to international markets? How can a local Agriculture and Food Processing company successfully enter international markets?arrow_forwardWhat is an example of how someone would explain how their past personal and professional experience makes you a quality candidate for a teaching position at an Elementary School as a K-6 Teacher?arrow_forwardI need answer typing clear urjent no chatgpt used pls i will give 5 Upvotes.arrow_forward

- How can a local tourism and hospitality company successfully enter international markets?arrow_forwardHow was Circuit City Company collapsed? And what was the sequence of time and events or problems? How to solve the issues, and could you help identify positions or titles. Sanitize all names and use only fictitious data. What is synthesize the qualitative research methodology of Case Study research? Please give some examples. How to use the practical of Lean Six Sigma to develop a business-facing DMAIC-based case studyarrow_forwardBUSINESS MODEL CANVAS: U.S ARMY key partners: Key activities: Key Resources: Value Propositions: Buy-in & Support: Deployment: Benficiaries: Mission budget/cost: Mission Achievement/ Impact factors: Please at least 4 for each categoryarrow_forward

- how you would best conduct a performance evaluation meeting with a subordinate (where an employee would receive their performance evaluation from their supervisor). Importantly, detail how a supervisor can best gain the concurrence from an employee on the evaluation itself, and to ensure that the employee’s performance will be modified as a result of appraisal meeting.arrow_forwardI need answer typing clear urjent no chatgpt used pls i will give 5 Upvotes.arrow_forwardassume that you are police commander which leads and supervises the department’s internal affairs division. Your goal is to reduce civilian complainants against personnel in the department. Using what you have learned and at least three scholarly sources, document two changes you see the department can implement, whether it be training, planning, mitigating, and resolving, to improve police/community relations.arrow_forward

- Ness Engineering is a private limited company mainly engaged in the continuous production and assembly of domestic products. The annual turnover is $900,000,000. The largest area of expenditure is raw materials and components where the annual spend is approximately $450,000,000. The Managing Director, Bill, considers that profit margins are too small and has asked you to suggest how profitability might be increased. Bill suggests that this might be done by appointing additional sales staff and by an advertising campaign, which would, hopefully, increase turnover and thereby reduce overhead cost per item. You find that purchasing is little more than a post-office function. Specifications are received from the design or user departments and sent either to supplies designated by the directors or to the supplier providing the cheapest quotation. The company does, in fact, deal with many suppliers and issues many orders for low-cost items. All purchasing is done by manual means. None of the…arrow_forwardThe oasis outpost of Abu Ilan, in the heart of the Negev desert, has a population of 20 Bedouin tribesmen and 20 Farima tribesmen. El Kamin, a nearby oasis, has a population of 32 Bedouins and 8 Farima. A lost Israeli soldier, accidentally separated from his army unit, is wandering through the desert and arrives at the edge of one of the oases. The soldier has no idea which oasis he has found, but the first person he spots at a distance is a Bedouin. 1. What is the probability that he wandered into Abu Ilan? 2. What is the probability that he is in El Kamin?arrow_forward2-22 The lost Israeli soldier mentioned in Problem 2-21 decides to rest for a few minutes before entering the desert oasis he has just found. Closing his eyes, he dozes off for 15 minutes, wakes, and walks toward the center of the oasis. The first person he spots this time he again recognizes as a Bedouin. What is the posterior probability that he is in El Kamin?*Note* 2-21 The oasis outpost of Abu Ilan, in the heart of the Negev desert, has a population of 20 Bedouin tribesmen and 20 Farima tribesmen. El Kamin, a nearby oasis, has a population of 32 Bedouins and 8 Farima. A lost Israeli soldier, accidentally separated from his army unit, is wandering through the desert and arrives at the edge of one of the oases. The soldier has no idea which oasis he has found, but the first person he spots at a distance is a Bedouin. What is the probability that he has wandered into Abu Ilan? What is the probability that he is in El Kamin?arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Management, Loose-Leaf VersionManagementISBN:9781305969308Author:Richard L. DaftPublisher:South-Western College Pub

Management, Loose-Leaf VersionManagementISBN:9781305969308Author:Richard L. DaftPublisher:South-Western College Pub- MarketingMarketingISBN:9780357033791Author:Pride, William MPublisher:South Western Educational Publishing