Concept explainers

Dwayne Cole, owner of a Florida firm that manufactures display cabinets, develops an 8-month aggregate plan. Demand and capacity (in units) are

The cost of producing each unit is $1,000 on regular time, $1,300 on overtime, and $1,800 on a subcontract. Inventory carrying cost is $200 per unit per month. There is no beginning or ending inventory in stock, and no backorders are permitted from period to period.

Let the production (workforce) vary by using regular time first, then overtime, and then subcontracting.

a) Set up a production plan that minimizes cost by producing exactly what the demand is each month. This plan allows no backorders or inventory. What is this plan’s cost?

b) Through better planning, regular time production can be set at exactly the same amount, 275 units, per month. If demand cannot be met there is no cost assigned to shortages and they will not be filled. Does this alter the solution?

c) If overtime costs per unit rise from $1,300 to $1,400, will your answer to (a) change? What if overtime costs then fall to $1,200?

a)

To determine: The total cost of the plan.

Introduction: The aggregate plan is the output of sales and operations planning. The major concern of aggregate planning is the production time and quantity for the intermediate future. Aggregate planning would encompass a time prospect of approximately 3 to 18 months.

Answer to Problem 19P

The total cost of the plan is $2,608,300.

Explanation of Solution

Given information:

Regular time cost per unit is given as $1,000, overtime cost is $1,300, and subcontract cost is $1,800 per unit. The capacity and demand are given as follows:

| Month | Demand | Regular time capacity | Overtime capacity | Subcontract capacity |

| Initial | 0 | 0 | 0 | 0 |

| January | 255 | 235 | 20 | 12 |

| February | 294 | 255 | 24 | 16 |

| March | 321 | 290 | 26 | 15 |

| April | 301 | 300 | 24 | 17 |

| May | 330 | 300 | 30 | 17 |

| June | 320 | 290 | 28 | 19 |

| July | 345 | 300 | 30 | 19 |

| August | 340 | 290 | 30 | 20 |

Calculate the total cost:

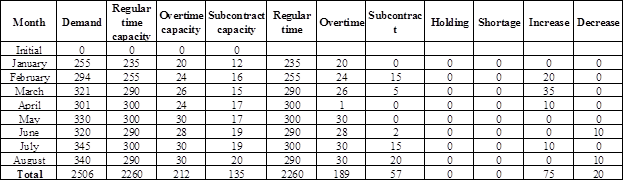

Table 1

Working note:

Demand, regular time capacity, overtime capacity, and subcontract capacity are given.

Determine regular time, overtime, and subcontract units for the month of January:

It is given that the demand for the month of January is 255 units. 235 units would be produced in the regular time (as the regular time capacity is 235). Remaining 20 units would be produced in the overtime (as the overtime capacity is 20). Hence, regular time unit is 235 units and overtime unit is 20 units.

Determine regular time, overtime, and subcontract units for the month of February:

It is given that the demand for the month of February is 294 units. 255 units would be produced in the regular time (as the regular time capacity is 255). From the remaining 39 units, 24 units would be produced in the overtime (as the overtime capacity is 24) and 15 units would be produced using subcontract (as the subcontract capacity is 16). Hence, regular time unit is 255 units, overtime unit is 24 units, and subcontract unit is 15 units.

Determine regular time, overtime, and subcontract units for the month of March:

It is given that the demand for the month of March is 321 units. 290 units would be produced in the regular time (as the regular time capacity is 290). From the remaining 31 units, 26 units would be produced in the overtime (as the overtime capacity is 26) and 5 units would be produced using subcontract (as the subcontract capacity is 15). Hence, regular time unit is 290 units, overtime unit is 26 units, and subcontract unit is 5 units.

Note: The procedure continues for all months.

Increase or decrease for the month of January:

There would be no increase or decrease for the month of January as there is no period compare.

Increase or decrease for the month of February:

Production in the month of January is 235 units and production in the month of February is 255 units. There is an increase of 20 units. Hence, there would be 20 units increase in February.

Increase or decrease for the month of March:

Production in the month of February is 255 units and production in the month of March is 290 units. There is an increase of 35 units. Hence, there would be 35 units increase in March.

Increase or decrease for the month of April:

Production in the month of March is 290 units and production in the month of April is 300 units. There is an increase of 10 units. Hence, there would be 10 units increase in April.

Increase or decrease for the month of May:

Production in the month of April is 300 units and production in the month of May is 300 units. As there is no change in the production units, there would not be any increase or decrease.

Increase or decrease for the month of June:

Production in the month of May is 300 units and production in the month of June is 290 units. There is a decrease of 10 units. Hence, there would be 10 units decrease in June.

Increase or decrease for the month of July:

Production in the month of June is 290 units and production in the month of July is 300 units. There is an increase of 10 units. Hence, there would be 10 units increase in July.

Increase or decrease for the month of August:

Production in the month of July is 300 units and production in the month of August is 290 units. There is a decrease of 10 units. Hence, there would be 10 units decrease in August.

Summary of the table:

| Type | Units | Cost |

| Regular time | 2,260 | $2,260,000 |

| Overtime | 189 | $245,700 |

| Subcontract | 57 | $102,600 |

| Holding | 0 | 0 |

| Shortage | 0 | 0 |

| Increase | 75 | 0 |

| Decrease | 20 | 0 |

| $2,608,300 |

Table 2

Working note:

Total units of regular time, overtime, subcontract, shortage, holding, increase, and decrease were calculated in theTable 1.

Calculate the regular time cost:

Regular time cost is calculated by multiplying regular time unit and the given regular time cost per unit. Hence, the regular time cost is $2,260,000.

Calculate the overtime cost:

Overtime cost is calculated by multiplying overtime unit and the given overtime cost per unit. Hence, the overtime cost is $245,700.

Calculate the subcontract cost:

Subcontract cost is calculated by multiplying subcontract unit and the given subcontract cost per unit. Hence, the subcontract cost is $102,600.

Calculate the increase and decrease cost:

As there is no increase or decrease cost per unit, it would remain 0.

Calculate the total cost:

Total cost is calculated by adding regular time cost, overtime cost, subcontract cost, holding cost, shortage cost, increase cost, and decrease cost.

Hence, the total cost of the plan is $2,608,300.

b)

To determine: The total cost of the plan.

Introduction: The aggregate plan is the output of sales and operations planning. The major concern of aggregate planning is the production time and quantity for the intermediate future. Aggregate planning would encompass a time prospect of approximately 3 to 18 months.

Answer to Problem 19P

The total cost of the plan is $2,585,100.

Explanation of Solution

Given information:

Regular time cost per unit is given as $1,000, overtime cost is $1,300, and subcontract cost is $1,800 per unit. The capacity and demand are given as follows:

| Month | Demand | Regular time capacity | Overtime capacity | Subcontract capacity |

| Initial | 0 | 0 | 0 | 0 |

| January | 255 | 275 | 20 | 12 |

| February | 294 | 275 | 24 | 16 |

| March | 321 | 275 | 26 | 15 |

| April | 301 | 275 | 24 | 17 |

| May | 330 | 275 | 30 | 17 |

| June | 320 | 275 | 28 | 19 |

| July | 345 | 275 | 30 | 19 |

| August | 340 | 275 | 30 | 20 |

Calculate the total cost:

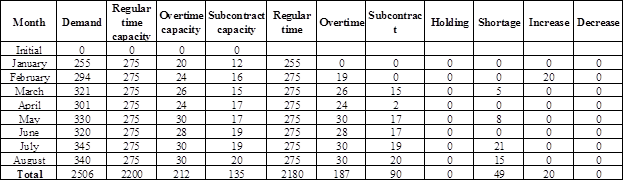

Table 3

Working note:

Demand, regular time capacity, overtime capacity, and subcontract capacity are given.

Determine regular time, overtime, and subcontract units for the month of January:

It is given that the demand for the month of January is 255 units. Whole 255 units would be produced in the regular time (as the regular time capacity is 275). Hence, regular time unit is 255 units.

Determine regular time, overtime, and subcontract units for the month of February:

It is given that the demand for the month of February is 294 units. 275 units would be produced in the regular time (as the regular time capacity is 275). Remaining 19 units would be produced in the overtime (as the overtime capacity is 24). Hence, regular time unit is 275 units and overtime unit is 19 units.

Determine regular time, overtime, and subcontract units for the month of March:

It is given that the demand for the month of March is 321 units. 275 units would be produced in the regular time (as the regular time capacity is 290). From the remaining 46 units, 26 units would be produced in the overtime (as the overtime capacity is 26) and 15 units would be produced using subcontract (as the subcontract capacity is 15). Hence, regular time unit is 275 units, overtime unit is 26 units, and subcontract unit is 15 units. Remaining 5 units is a shortage.

Note: The procedure continues for all months.

Increase or decrease for the month of January:

There would be no increase or decrease for the month of January as there is no period compare.

Increase or decrease for the month of February:

Production in the month of January is 255 units and production in the month of February is 275 units. There is an increase of 20 units. Hence, there would be 20 units increase in February.

Increase or decrease from the month of March to August:

As the production for regular time remains the same, there would be no increase or decrease from the month of March to August.

Summary of the table:

| Type | Units | Cost |

| Regular time | 2,180 | $2,180,000 |

| Overtime | 187 | $243,100 |

| Subcontract | 90 | $162,000 |

| Holding | 0 | 0 |

| Shortage | 49 | 0 |

| Increase | 20 | 0 |

| Decrease | 0 | |

| $2,585,100 |

Table 4

Working note:

Total units of regular time, overtime, subcontract, shortage, holding, increase, and decrease were calculated in theTable 3.

Calculate the regular time cost:

Regular time cost is calculated by multiplying regular time unit and the given regular time cost per unit. Hence, the regular time cost is $2,180,000.

Calculate the overtime cost:

Overtime cost is calculated by multiplying overtime unit and the given overtime cost per unit. Hence, the overtime cost is $243,100.

Calculate the subcontract cost:

Subcontract cost is calculated by multiplying subcontract unit and the given subcontract cost per unit. Hence, the subcontract cost is $162,000.

Calculate the increase and decrease cost:

As there is no increase or decrease cost per unit, it would remain 0.

Calculate the total cost:

Total cost is calculated by adding regular time cost, overtime cost, subcontract cost, holding cost, shortage cost, increase cost, and decrease cost.

Hence, the total cost of the plan is $2,585,100.

c)

To determine: The total cost of the plan, if the overtime increased to $1,400.

Introduction: The aggregate plan is the output of sales and operations planning. The major concern of aggregate planning is the production time and quantity for the intermediate future. Aggregate planning would encompass a time prospect of approximately 3 to 18 months.

Answer to Problem 19P

The total cost of the plan is $2,627,200.

Explanation of Solution

Given information:

Regular time cost per unit is given as $1,000, overtime cost is $1,400, and subcontract cost is $1,800 per unit. The capacity and demand are given as follows:

| Month | Demand | Regular time capacity | Overtime capacity | Subcontract capacity |

| Initial | 0 | 0 | 0 | 0 |

| January | 255 | 235 | 20 | 12 |

| February | 294 | 255 | 24 | 16 |

| March | 321 | 290 | 26 | 15 |

| April | 301 | 300 | 24 | 17 |

| May | 330 | 300 | 30 | 17 |

| June | 320 | 290 | 28 | 19 |

| July | 345 | 300 | 30 | 19 |

| August | 340 | 290 | 30 | 20 |

Calculate the total cost:

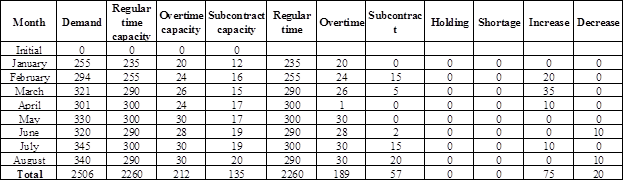

Table 5

Working note:

Demand, regular time capacity, overtime capacity, and subcontract capacity are given.

Determine regular time, overtime, and subcontract units for the month of January:

It is given that the demand for the month of January is 255 units. 235 units would be produced in the regular time (as the regular time capacity is 235). Remaining 20 units would be produced in the overtime (as the overtime capacity is 20). Hence, regular time unit is 235 units and overtime unit is 20 units.

Determine regular time, overtime, and subcontract units for the month of February:

It is given that the demand for the month of February is 294 units. 255 units would be produced in the regular time (as the regular time capacity is 255). From the remaining 39 units, 24 units would be produced in the overtime (as the overtime capacity is 24) and 15 units would be produced using subcontract (as the subcontract capacity is 16). Hence, regular time unit is 255 units, overtime unit is 24 units, and subcontract unit is 15 units.

Determine regular time, overtime, and subcontract units for the month of March:

It is given that the demand for the month of March is 321 units. 290 units would be produced in the regular time (as the regular time capacity is 290). From the remaining 31 units, 26 units would be produced in the overtime (as the overtime capacity is 26) and 5 units would be produced using subcontract (as the subcontract capacity is 15). Hence, regular time unit is 290 units, overtime unit is 26 units, and subcontract unit is 5 units.

Note: The procedure continues for all months.

Increase or decrease for the month of January:

There would be no increase or decrease for the month of January as there is no period compare.

Increase or decrease for the month of February:

Production in the month of January is 235 units and production in the month of February is 255 units. There is an increase of 20 units. Hence, there would be 20 units increase in February.

Increase or decrease for the month of March:

Production in the month of February is 255 units and production in the month of March is 290 units. There is an increase of 35 units. Hence, there would be 35 units increase in March.

Increase or decrease for the month of April:

Production in the month of March is 290 units and production in the month of April is 300 units. There is an increase of 10 units. Hence, there would be 10 units increase in April.

Increase or decrease for the month of May:

Production in the month of April is 300 units and production in the month of May is 300 units. As there is no change in the production units, there would not be any increase or decrease.

Increase or decrease for the month of June:

Production in the month of May is 300 units and production in the month of June is 290 units. There is a decrease of 10 units. Hence, there would be 10 units decrease in June.

Increase or decrease for the month of July:

Production in the month of June is 290 units and production in the month of July is 300 units. There is an increase of 10 units. Hence, there would be 10 units increase in July.

Increase or decrease for the month of August:

Production in the month of July is 300 units and production in the month of August is 290 units. There is a decrease of 10 units. Hence, there would be 10 units decrease in August.

Calculate the total cost if the overtime cost per unit increased to $1,400:

| Type | Units | Cost |

| Regular time | 2,260 | $2,260,000 |

| Overtime | 189 | $264,600 |

| Subcontract | 57 | $102,600 |

| Holding | 0 | 0 |

| Shortage | 0 | 0 |

| Increase | 75 | 0 |

| Decrease | 20 | 0 |

| $2,627,200 |

Table 6

Working note:

Total units of regular time, overtime, subcontract, shortage, holding, increase, and decrease were calculated in theTable 5.

Calculate the regular time cost:

Regular time cost is calculated by multiplying regular time unit and the given regular time cost per unit. Hence, the regular time cost is $2,260,000.

Calculate the overtime cost:

Overtime cost is calculated by multiplying overtime unit and the given overtime cost per unit. Hence, the overtime cost is $264,600.

Calculate the subcontract cost:

Subcontract cost is calculated by multiplying subcontract unit and the given subcontract cost per unit. Hence, the subcontract cost is $102,600.

Calculate the increase and decrease cost:

As there is no increase or decrease cost per unit, it would remain 0.

Calculate the total cost:

Total cost is calculated by adding regular time cost, overtime cost, subcontract cost, holding cost, shortage cost, increase cost, and decrease cost.

Hence, the total cost of the plan is $2,627,200.

Calculate the total cost if the overtime cost per unit increased to $1,200:

| Type | Units | Cost |

| Regular time | 2,260 | $2,260,000 |

| Overtime | 189 | $226,800 |

| Subcontract | 57 | $102,600 |

| Holding | 0 | 0 |

| Shortage | 0 | 0 |

| Increase | 75 | 0 |

| Decrease | 20 | 0 |

| $2,589,400 |

Table 7

Working note:

Total units of regular time, overtime, subcontract, shortage, holding, increase, and decrease were calculated in theTable 6.

Calculate the regular time cost:

Regular time cost is calculated by multiplying regular time unit and the given regular time cost per unit. Hence, the regular time cost is $2,260,000.

Calculate the overtime cost:

Overtime cost is calculated by multiplying overtime unit and the given overtime cost per unit. Hence, the overtime cost is $264,600.

Calculate the subcontract cost:

Subcontract cost is calculated by multiplying subcontract unit and the given subcontract cost per unit. Hence, the subcontract cost is $102,600.

Calculate the increase and decrease cost:

As there is no increase or decrease cost per unit, it would remain 0.

Calculate the total cost:

Total cost is calculated by adding regular time cost, overtime cost, subcontract cost, holding cost, shortage cost, increase cost, and decrease cost.

Hence, the total cost of the plan is $2,589,400.

Want to see more full solutions like this?

Chapter 13 Solutions

EBK PRINCIPLES OF OPERATIONS MANAGEMENT

- PP.52 A manufacturer of solid state drives (SSDs) has projected the next six months of demand to be as shown the table below: Supply/Demand Info Beginning Jan Feb Mar Apr May Jun Forecast (demand) 53,800 53,400 51,000 63,800 49,200 59,000 Regular production Overtime production Subcontract production Ending inventory 4,000 Hired employees Fired employees Total employees 190 Cost variables are as follows: Cost Variables Labor cost/hour $16 Overtime cost/unit $39 Subcontracting cost/unit $35 Holding cost/unit/month $14 Hiring cost/employee $3,100 Firing cost/employee $5,500 Here is some additional relevant (capacity) information: Capacity Information Total labor hours/SSD 4 Regular production units/employee/month 200…arrow_forwardDiscuss how a human resource professional can better gain the confidence of senior management and, thereby, become a key participant/player in the organization’s future.arrow_forwardPP.63 Jupiter, a large candy company, is having great success with its "Swan" family of candy bars. Due to a number of factors they like to plan their production at least six months into the future. The table below contains their demand projections (in tons) for April through September: Supply/Demand Info Beginning Apr May Jun Jul Aug Sep Predicted Sales 45,500 45,100 51,900 52,800 47,900 47,200 Regular production Overtime production Subcontract production Ending inventory 14,400 Hired employees Fired employees Total employees 423 Cost variables are as follows: Cost Variables Labor cost/hour $13 Overtime cost/ton $30 Subcontracting cost/ton $28 Holding cost/ton/month $14 Hiring cost/employee $3,700 Firing cost/employee $5,800 Here is some additional…arrow_forward

- What are the responsibilities and duties of a consultant for a local company who is considering expanding its operations to international markets? How can a local Agriculture and Food Processing company successfully enter international markets?arrow_forwardWhat is an example of how someone would explain how their past personal and professional experience makes you a quality candidate for a teaching position at an Elementary School as a K-6 Teacher?arrow_forwardI need answer typing clear urjent no chatgpt used pls i will give 5 Upvotes.arrow_forward

- How can a local tourism and hospitality company successfully enter international markets?arrow_forwardHow was Circuit City Company collapsed? And what was the sequence of time and events or problems? How to solve the issues, and could you help identify positions or titles. Sanitize all names and use only fictitious data. What is synthesize the qualitative research methodology of Case Study research? Please give some examples. How to use the practical of Lean Six Sigma to develop a business-facing DMAIC-based case studyarrow_forwardBUSINESS MODEL CANVAS: U.S ARMY key partners: Key activities: Key Resources: Value Propositions: Buy-in & Support: Deployment: Benficiaries: Mission budget/cost: Mission Achievement/ Impact factors: Please at least 4 for each categoryarrow_forward

- how you would best conduct a performance evaluation meeting with a subordinate (where an employee would receive their performance evaluation from their supervisor). Importantly, detail how a supervisor can best gain the concurrence from an employee on the evaluation itself, and to ensure that the employee’s performance will be modified as a result of appraisal meeting.arrow_forwardI need answer typing clear urjent no chatgpt used pls i will give 5 Upvotes.arrow_forwardassume that you are police commander which leads and supervises the department’s internal affairs division. Your goal is to reduce civilian complainants against personnel in the department. Using what you have learned and at least three scholarly sources, document two changes you see the department can implement, whether it be training, planning, mitigating, and resolving, to improve police/community relations.arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage LearningMarketingMarketingISBN:9780357033791Author:Pride, William MPublisher:South Western Educational Publishing

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage LearningMarketingMarketingISBN:9780357033791Author:Pride, William MPublisher:South Western Educational Publishing