Concept explainers

New England Foundry

For more than 75 years, New England Foundry, Inc., (NEFI), has manufactured wood stoves for home use. In recent years, with increasing energy prices, President George Mathison has seen sales triple. This dramatic increase has made it difficult for George to maintain quality in all his wood stoves and related products.

Unlike other companies manufacturing wood stoves, NEFI is in the business of making only stoves and stove-related products. Its major products are the Warmglo I, the Warmglo II, the Warmglo III, and the Warmglo IV. The Warmglo I is the smallest wood stove, with a heat output of 30,000 BTUs, and the Warmglo IV is the largest, with a heat output of 60,000 BTUs.

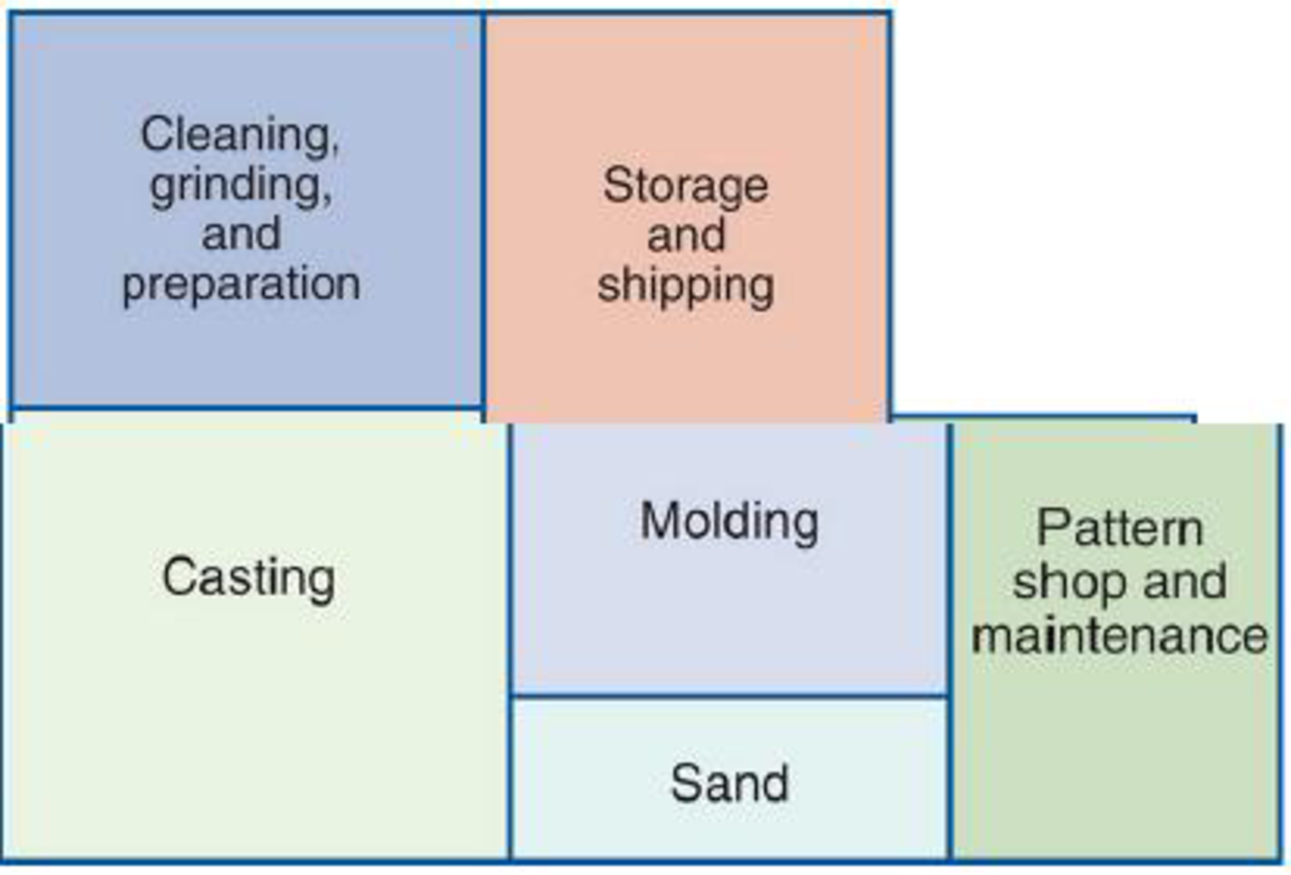

The Warmglo III outsold all other models by a wide margin. Its heat output and available accessories were ideal for the typical home. The Warmglo III also had a number of other outstanding features that made it one of the most attractive and heat-efficient stoves on the market. These features, along with the accessories, resulted in expanding sales and prompted George to build a new factory to manufacture the Warmglo III model. An overview diagram of the factory is shown in Figure D.6.

Figure D.6 Overview of Factory

The new foundry used the latest equipment, including a new Disamatic that helped in manufacturing stove parts. Regardless of new equipment or procedures, casting operations have remained basically unchanged for hundreds of years. To begin with, a wooden pattern is made for every cast-iron piece in the stove. The wooden pattern is an exact duplicate of the cast-iron piece that is to be manufactured. All NEFI patterns are made by Precision Patterns, Inc. and are stored in the pattern shop and maintenance room. Next, a specially formulated sand is molded around the wooden pattern. There can be two or more sand molds for each pattern. The sand is mixed and the molds are made in the molding room. When the wooden pattern is removed, the resulting sand molds form a negative image of the desired casting.

Next, molds are transported to the casting room, where molten iron is poured into them and allowed to cool. When the iron has solidified, molds are moved into the cleaning, grinding, and preparation room, where they are dumped into large vibrators that shake most of the sand from the casting. The rough castings are then subjected to both sandblasting to remove the rest of the sand and grinding to finish some of their surfaces. Castings are then painted with a special heat-resistant paint, assembled into workable stoves, and inspected for manufacturing defects that may have gone undetected. Finally, finished stoves are moved to storage and shipping, where they are packaged and transported to the appropriate locations.

At present, the pattern shop and the maintenance department are located in the same room. One large counter is used by both maintenance personnel, who store tools and parts (which are mainly used by the casting department), and sand molders, who need various patterns for the molding operation. Pete Nawler and Bob Dillman, who work behind the counter, can service a total of 10 people per hour (about 5 per hour each). On average, 4 people from casting and 3 from molding arrive at the counter each hour. People from molding and casting departments arrive randomly, and to be served, 1hey form a single line.

Pete and Bob have always had a policy of first come, first served. Because of the location of the pattern shop and maintenance department, it takes an average of 3 minutes for an individual from the casting department to walk to the pattern and maintenance room, and it takes about 1 minute for an individual to walk from the molding department to the pattern and maintenance room.

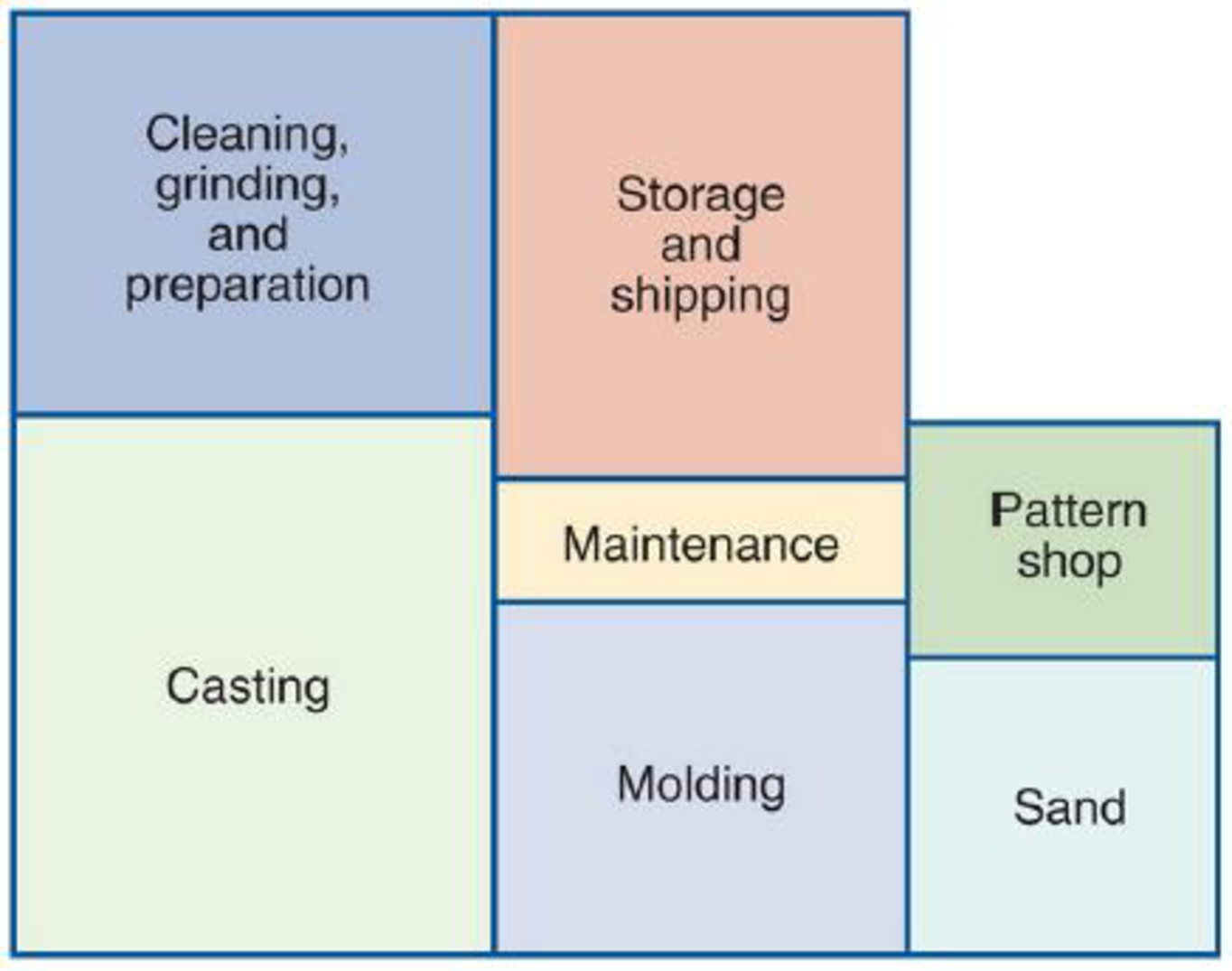

After observing the operation of the pattern shop and maintenance room for several weeks, George decided to make some changes to the factory layout. An overview of these changes appears in Figure D.7.

Figure D.7 Overview of Factory after Changes

Separating the maintenance shop from the pattern shop would have a number of advantages. It would take people from the casting department only 1 minute instead of 3 to get to the new maintenance room. The time from molding to the pattern shop would be unchanged. Using motion and time studies, George was also able to determine that improving the layout of the maintenance room would allow Bob to serve 6 people from the casting department per hour; improving the layout of the pattern department would allow Pete to serve 7 people from the molding shop per hour.

3. Should George have made the change in layout?

Want to see the full answer?

Check out a sample textbook solution

Chapter D Solutions

Operations Management: Sustainability and Supply Chain Management (12th Edition)

- A coworker suggests that the company where you both work would be much more effective if there were no organizational politics. Please in your personal and detailed opinion, What would you say to this person in reply?arrow_forwardWhat is a bottleneck? Would you try to reduce a bottleneck? Why or why not? Please provide a referencearrow_forwardYour firm has been the auditor of Caribild Products, a listed company, for a number of years. The engagement partner has asked you to describe the matters you would consider when planning the audit for the year ended 31January 2022. During recent visit to the company you obtained the following information: (a) The management accounts for the 10 months to 30 November 2021 show a revenue of $260 million and profit before tax of $8 million. Assume sales and profits accrue evenly throughout the year. In the year ended 31 January 2021 Caribild Products had sales of $220 million and profit before tax of $16 million. (b) The company installed a new computerised inventory control system which has operated from 1 June 2021. As the inventory control system records inventory movements and current inventory quantities, the company is proposing: (i) To use the inventory quantities on the computer to value the inventory at the year-end (ii) Not to carry out an inventory count at the year-end (c)…arrow_forward

- Develop and implement a complex and scientific project for an organisation of your choice. please include report include the following: Introduction Background research to the project The 5 basic phases in the project management process Project Initiation Project Planning Project Execution Project Monitoring and Controlling Project Closing Conclusionarrow_forwardNot use ai pleasearrow_forwardSam's Pet Hotel operates 51 weeks per year, 6 days per week, and uses a continuous review inventory system. It purchases kitty litter for $11.00 per bag. The following information is available about these bags: > Demand 95 bags/week > Order cost $52.00/order > Annual holding cost = 25 percent of cost > Desired cycle-service level = 80 percent >Lead time 4 weeks (24 working days) > Standard deviation of weekly demand = 15 bags > Current on-hand inventory is 320 bags, with no open orders or backorders. a. Suppose that the weekly demand forecast of 95 bags is incorrect and actual demand averages only 75 bags per week. How much higher will total costs be, owing to the distorted EOQ caused by this forecast error? The costs will be $ higher owing to the error in EOQ. (Enter your response rounded to two decimal places.)arrow_forward

- Sam's Pet Hotel operates 50 weeks per year, 6 days per week, and uses a continuous review inventory system. It purchases kitty litter for $10.50 per bag. The following information is available about these bags: > Demand = 95 bags/week > Order cost = $55.00/order > Annual holding cost = 35 percent of cost > Desired cycle-service level = 80 percent > Lead time = 4 weeks (24 working days) > Standard deviation of weekly demand = 15 bags > Current on-hand inventory is 320 bags, with no open orders or backorders. a. Suppose that the weekly demand forecast of 95 bags is incorrect and actual demand averages only 75 bags per week. How much higher will total costs be, owing to the distorted EOQ caused by this forecast error? The costs will be $ 10.64 higher owing to the error in EOQ. (Enter your response rounded to two decimal places.) b. Suppose that actual demand is 75 bags but that ordering costs are cut to only $13.00 by using the internet to automate order placing. However, the buyer does…arrow_forwardBUS-660 Topic 4: Intege... W Midterm Exam - BUS-66... webassign.net b Answered: The binding c... × W Topic 4 Assignment - BU... how to get more chegg... b My Questions | bartleby + macbook screenshot - G... C Consider the following m... As discussed in Section 8.3, the Markowitz model uses the variance of the portfolio as the measure of risk. However, variance includes deviations both below and above the mean return. Semivariance includes only deviations below the mean and is considered by many to be a better measure of risk. (a) Develop a model that minimizes semivariance for the Hauck Financial data given in the file HauckData with a required return of 10%. Assume that the five planning scenarios in the Hauck Financial Services model are equally likely to occur. Hint: Modify model (8.10)-(8.19). Define a variable d for each 5 - scenario and let d≥ Ŕ – R¸ with d¸ ≥ 0. Then make the objective function: Min 1 5 Σας Let Min s.t. 15 FS = proportion of portfolio invested in the foreign…arrow_forwardOn a daily basis, the van is dispatched from Maplewood Hospital to pickup blood and platelet donations made at its local donation centers. The distances in miles between all locations may be found in the table below. Click the icon to view mileage data for Vampire Van. a. The van travels from the Hospital (A) to (B) to (C) to (D) to (E) and then returns to the Hospital (A). What is the total number of miles that the van must travel using this route? Route ABCDEA requires a total distance of miles. (Enter your response rounded to one decimal place.) More Info Maplewood City Center Westbrook Hospital (A) Donation Site (B) Donation Site (C) Municipal Park Donation Site (D) Valley Hills Donation Site (E) Maplewood 3.1 5.3 3.2 4.4 Hospital (A) City Center 3.1 6.7 2.2 4.3 Donation Site (B) Westbrook 5.3 Donation Site (C) 19 6.7 | 6.2 2.5 Municipal Park 3.2 2.2 6.2 | 4.6 Donation Site (D) Valley Hills 4.4 4.3 2.5 4.6 Donation Site (E) - ☑arrow_forward

- The Harvey Motorcycle Company produces three models: the Tiger, a sure-footed dirt bike; the LX2000, a nimble cafe racer; and the Golden, a large interstate tourer. The month's master production schedule calls for the production of 32 Goldens, 31 LX2000s, and 38 Tigers per 10-hour shift. What average cycle time is required for the assembly line to achieve the production quota in 10 hours? 0.099 hours per motorcycle. (Enter your response rounded to three decimal places.) If mixed-model scheduling is used, how many of each model will be produced before the production cycle is repeated? The greatest common divisor of the production requirements is Therefore, the Harvey Motorcycle Company will produce Goldens, LX2000s, and Tigers. (Enter your responses as integers.)arrow_forwardThe Harvey Motorcycle Company produces three models: the Tiger, a sure-footed dirt bike; the LX2000, a nimble cafe racer; and the Golden, a large interstate tourer. The month's master production schedule calls for the production of 32 Goldens, 31 LX2000s, and 38 Tigers per 10-hour shift. What average cycle time is required for the assembly line to achieve the production quota in 10 hours? hours per motorcycle. (Enter your response rounded to three decimal places.)arrow_forwardThe binding constraints for this problem are the second and third constraints are binding. Min x1 + 2x2 s.t. x1 + x2 ≤ 300 2x1 + x2 ≥ 400 2x1 + 5x2 ≥750 X1, X220 (a) Keeping the second objective function coefficient fixed at 2, over what range can the first objective function coefficient vary before there is a change in the optimal solution point? The first objective coefficient can from a low of to a high of (b) Keeping the first objective function coefficient fixed at 1, over what range can the second objective function coefficient vary before there is a change in the optimal solution point? The second objective coefficient can from a low of to a high of (c) If the objective function becomes Min 1.5x₁ + 2x2, what will be the optimal values of x1 and x2? x1 = X2 = What is the value of the objective function at the minimum? (d) If the objective function becomes Min 7x₁ + 6x2, what constraints will be binding? (Select all that apply.) First Constraint Second Constraint Third Constraint…arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning- MarketingMarketingISBN:9780357033791Author:Pride, William MPublisher:South Western Educational Publishing