(a)

Interpretation:

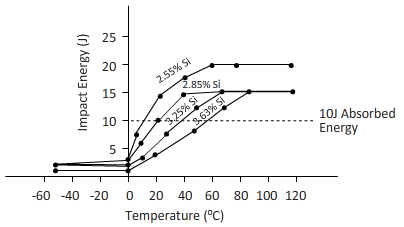

The transition temperature of each ductile cast iron considering energy absorbed in the ductile and brittle region by plotting results of Charpy impact test.

Concept Introduction:

Here, the graph for ductile cast iron with the different silicon content needs to be plotted. The graph represents temperature distribution vs. impact energy of each ductile cast iron. The transition temperature is obtained by absorbed energy in the brittle and ductile region.

Answer to Problem 6.66P

The transition temperature of each ductile cast iron are:

- Ductile cast iron with 2.55%Si = 26.56 0C

- Ductile cast iron with 2.85% Si = 35.93 0C

- Ductile cast iron with 3.25% Si = 45 0C

- Ductile cast iron with 3.63% Si = 65 0C

Explanation of Solution

Given Information:

| Test Temperature (0C) | 2.55%Si | 2.85%Si | 3.25%Si | 3.63%Si |

| -50 | 2.5 | 2.5 | 2 | 2 |

| -5 | 3 | 2.5 | 2 | 2 |

| 0 | 6 | 5 | 3 | 2.5 |

| 25 | 13 | 10 | 7 | 4 |

| 50 | 17 | 14 | 12 | 8 |

| 75 | 19 | 16 | 16 | 13 |

| 100 | 19 | 16 | 16 | 16 |

| 125 | 19 | 16 | 16 | 16 |

Calculations:

Transition temperature can be calculated by finding mean absorbed energy in the brittle and ductile region.

Thus,

- For 2.55%Si Ductile cast iron:

- For 2.85%Si Ductile cast iron:

- For 3.25%Si Ductile cast iron:

- For 3.63%Si Ductile cast iron:

Mean absorbed energy,

Transition temperature for 2.55%Si Ductile cast iron by interpolation,

Mean absorbed energy,

Transition temperature for 2.85%Si Ductile cast iron by interpolation,

Mean absorbed energy,

Transition temperature for 3.25%Si Ductile cast iron by interpolation,

Mean absorbed energy,

Transition temperature for 3.63%Si Ductile cast iron by interpolation,

(b)

Interpretation:

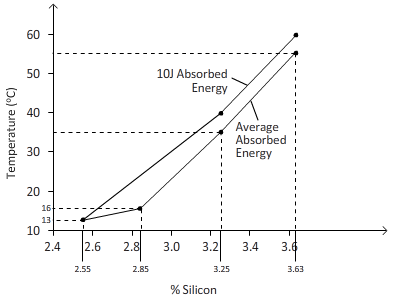

The transition temperature which provides 10 J of absorbed energy during the Charpy impact test needs to be determined.

Concept Introduction:

The transition temperature at 10 J absorbed energy can be calculated by considering the graph of temperature distribution vs. impact energy of each ductile cast iron.

Answer to Problem 6.66P

The transition temperature of each ductile cast iron for 10J of absorbed energy are:

- Ductile cast iron with 2.55%Si = 14.28 0C

- Ductile cast iron with 2.85% Si = 25 0C

- Ductile cast iron with 3.25% Si = 40 0C

- Ductile cast iron with 3.63% Si = 60 0C

Explanation of Solution

The transition temperature of each steel at 10J impact energy can be obtained from interpolation easily

- For 2.55%Si Ductile cast iron:

- For 2.85%Si Ductile cast iron:

- For 3.25%Si Ductile cast iron:

- For 3.63%Si Ductile cast iron:

(c)

Interpretation:

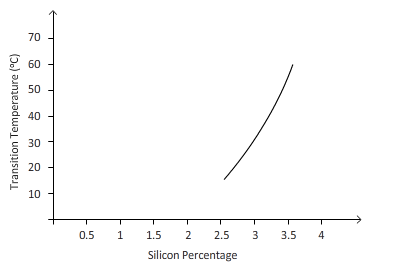

The effect of silicon on the toughness of the ductile cast iron needs to be explained by plotting results of temperature versus silicon content. The maximum content of silicon used in ductile cast iron needs to be determined, when the part is used at 250C.

Concept Introduction:

Here, the graph for silicon content vs. temperature needs to be plotted. The graph represents temperature distribution with silicon content in ductile cast iron.

Answer to Problem 6.66P

Considering the graph for silicon content vs. temperature, as silicon content increases, toughness decreases.

When ductile cast iron is used at 25 0C, there should be at least 2.9% silicon allowable in cast iron.

Explanation of Solution

Following are the results of transition temperatures for different types of silicon content in ductile cast iron.

| Silicon content (%) | Transition Temperature (0C) |

| 2.55 | 15 |

| 2.85 | 25 |

| 3.25 | 40 |

| 3.63 | 60 |

Following graph shows the distribution of temperatures with different silicon content in ductile cast iron.

Effect of silicon on the toughness of ductile cast iron:

- According to the graph, the toughness of material decreases with an increase in the percentage of silicon.

- Also, transition temperature increases with an increase in silicon content in ductile cast iron.

- Hence from the graph, when ductile cast iron is used at 25 0C, maximum 2.9% silicon is permissible in cast iron.

Want to see more full solutions like this?

Chapter 6 Solutions

Essentials Of Materials Science And Engineering

- A 1.8m x 1.8m footing is located at a depth of 1 m below the ground surface in a deep deposit of compacted sand (f'= 33 , f' = 28 , γ = 17.5 kN/m). Calculate the ultimate net bearing capacity considering several factors (e.g., shape, depth, and inclination) when the groundwater table is located (a) at 5 m below the footing base, (b) at the ground surface, (c) at the footing base, and (d) at 1.5 m below the footing base. Also, explain the effects of the groundwater levels in the bearing capacities of the footing with your own words. If the information is not given for the calculation, please assume it reasonably.arrow_forward1 Vo V₁ V3 V₂ V₂ 2arrow_forward1 Vo V₁ V3 V₂ V₂ 2arrow_forward

- Preparing for a testarrow_forwardHints: Find the closed loop transfer function and then plot the step response for diFerentvalues of K in MATLAB. Show step response plot for different values of K. Auto Controls Show solutions and provide matlab code NO COPIED ANSWERS OR WILL REPORT!!!! Use own solutionarrow_forward1 Vo V₁ V3 V₂ V₂ 2arrow_forward

- Findings revealed that employee ignorance and nwegligence towards it cybersecurity strategy is the reason for the increase in successful cyberattacks. provide a detailed recommendation to remedy this problem along with a conclusionarrow_forwardcomputer security and networkrow Transposition is a form of permutation cipher which involve writing the plaintext out in rows and then reading the ciphertext off in columns one by one.Encrypt the following plaintext using ROW Transposition cipher given the key as (5 8 7 10 9 6 4 3 1 2 11) PlainText=STOP STALKING ON SOCIAL MEDIA AND IMMIDIATELY START READING BOOK steps ın the most comprehensıve way most understandingarrow_forwardI need help to solve a simple problem using Grover’s algorithm, where the solution is not necessarily known beforehand. The problem is a 2×2 binary sudoku with two rules: • No column may contain the same value twice. • No row may contain the same value twice. Each square in the sudoku is assigned to a variable as follows: We want to design a quantum circuit that outputs a valid solution to this sudoku. While using Grover’s algorithm for this task is not necessarily practical, the goal is to demonstrate how classical decision problems can be converted into oracles for Grover’s algorithm. Turning the Problem into a Circuit To solve this, an oracle needs to be created that helps identify valid solutions. The first step is to construct a classical function within a quantum circuit that checks whether a given state satisfies the sudoku rules. Since we need to check both columns and rows, there are four conditions to verify: v0 ≠ v1 # Check top row v2 ≠ v3 # Check bottom row…arrow_forward

- 7.18 Determine the discharge in the pipe and the pressure at point B. Neglect head losses. Assume α = 1.0 at all locations. 1.5 m Water B 3.5 m 40 cm diameter -20 cm diameter nozzle Problem 7.18arrow_forwardA robot gripper is shown on Fig.1a. The block diagram of the control system is shown in Fig.1b. This system is conditionally stable because it is stable only for a range of the gain K. Using the Routh-Hurwitz criterion method to determine the range of gain for which the system is stable. Find the steady-state error due to unit step input. Sketch the root locus of the system and analyze its stability. Find the value of K so that the phase margin is minimum, and record the values of the phase margin, gain margin, Mr, and BW. Then draw the Bode plot of the system and discuss its stability using the Nyquist stability method. What is the value of this maximum overshoot for both large and small values of K due to unit step input? Draw the response of the open-loop and closed-loop of the system according to the unit step system for k=15, 25, 50. Discuss how to improve the system response if needed.arrow_forwardPlease show the stepsarrow_forward

MATLAB: An Introduction with ApplicationsEngineeringISBN:9781119256830Author:Amos GilatPublisher:John Wiley & Sons Inc

MATLAB: An Introduction with ApplicationsEngineeringISBN:9781119256830Author:Amos GilatPublisher:John Wiley & Sons Inc Essentials Of Materials Science And EngineeringEngineeringISBN:9781337385497Author:WRIGHT, Wendelin J.Publisher:Cengage,

Essentials Of Materials Science And EngineeringEngineeringISBN:9781337385497Author:WRIGHT, Wendelin J.Publisher:Cengage, Industrial Motor ControlEngineeringISBN:9781133691808Author:Stephen HermanPublisher:Cengage Learning

Industrial Motor ControlEngineeringISBN:9781133691808Author:Stephen HermanPublisher:Cengage Learning Basics Of Engineering EconomyEngineeringISBN:9780073376356Author:Leland Blank, Anthony TarquinPublisher:MCGRAW-HILL HIGHER EDUCATION

Basics Of Engineering EconomyEngineeringISBN:9780073376356Author:Leland Blank, Anthony TarquinPublisher:MCGRAW-HILL HIGHER EDUCATION Structural Steel Design (6th Edition)EngineeringISBN:9780134589657Author:Jack C. McCormac, Stephen F. CsernakPublisher:PEARSON

Structural Steel Design (6th Edition)EngineeringISBN:9780134589657Author:Jack C. McCormac, Stephen F. CsernakPublisher:PEARSON Fundamentals of Materials Science and Engineering...EngineeringISBN:9781119175483Author:William D. Callister Jr., David G. RethwischPublisher:WILEY

Fundamentals of Materials Science and Engineering...EngineeringISBN:9781119175483Author:William D. Callister Jr., David G. RethwischPublisher:WILEY