Concept explainers

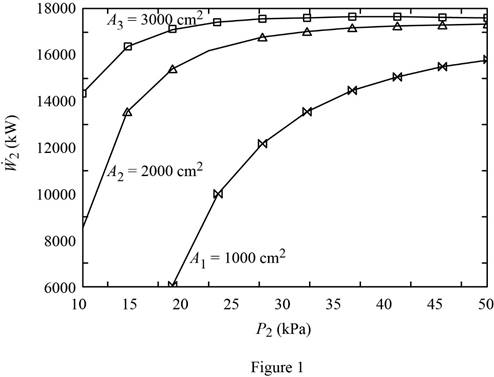

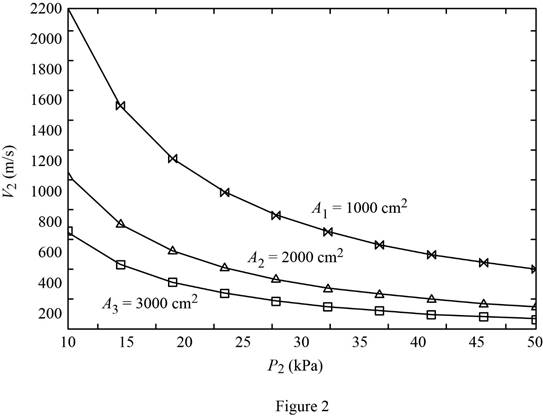

Reconsider Prob. 5–178. Using appropriate software, investigate the effects of turbine exit area and turbine exit pressure on the exit velocity and power output of the turbine. Let the exit pressure vary from 10 to 50 kPa (with the same quality), and let the exit area vary from 1000 to 3000 cm2. Plot the exit velocity and the power outlet against the exit pressure for the exit areas of 1000, 2000, and 3000 cm2, and discuss the

results.

5–178 Steam enters a turbine steadily at 7 MPa and 600°C with a velocity of 60 m/s and leaves at 25 kPa with a quality of 95 percent. A heat loss of 20 kJ/kg occurs during the process. The inlet area of the turbine is 150 cm2, and the exit area is 1400 cm2. Determine (a) the mass flow rate of the steam, (b) the exit velocity, and (c) the power output.

Plot the exit pressure against power output of turbine and exit pressure against exit velocity for varying pressure from

Answer to Problem 179RP

The plot for the exit pressure against power output of turbine and exit pressure against exit velocity for varying pressure from

Explanation of Solution

The turbine operates steadily. Hence, the inlet and exit mass flow rates are equal.

Write the formula for inlet mass flow rate.

Here, the cross-sectional area is

At inlet:

The steam is at the state of superheated condition.

Refer Table A-6, “Superheated water”.

Obtain the inlet enthalpy

The turbine operates steadily. Hence, the inlet and exit mass flow rates are equal.

Write the formula for exit mass flow rate.

Here, the cross-sectional area is

Rearrange the Equation (II) to obtain exit velocity

At exit:

Consider the exit pressure

The steam is with the quality of

Write the formula for exit enthalpy

Write the formula for exit specific volume

Here, the enthalpy is

Refer Table A-5, “Saturated water—Pressure table”.

Obtain the following corresponding to the pressure of

Consider the steam flows at steady state. Hence, the inlet and exit mass flow rates are equal.

Write the energy rate balance equation for one inlet and one outlet system.

Here, the rate of heat transfer is

The refrigerant flows at steady state through the compressor. Hence, the rate of change in net energy of the system becomes zero.

Heat loss occurs at the rate of

The Equations (VI) reduced as follows to obtain the work output

Here,

Rewrite the Equation (VII) as follows.

Conclusion:

Substitute

Substitute

Equation (V).

Substitute

Consider the exit area

Substitute

Equation (III).

Substitute

The exit velocity

Using excel spread sheet, the exit velocity

| S.No. | |||

| 1 | 10 | 2253.540216 | –22171.1196 |

| 2 | 15 | 1539.230498 | –514.857057 |

| 3 | 20 | 1174.871104 | 7295.806083 |

| 4 | 25 | 952.9435377 | 10965.91684 |

| 5 | 30 | 803.2150134 | 12968.62817 |

| 6 | 40 | 613.4390747 | 14943.44488 |

| 7 | 50 | 497.7670121 | 15822.49054 |

Table 1

Similarly, the exit velocity

| S.No. | |||

| 1 | 10 | 1126.770108 | 8623.292217 |

| 2 | 15 | 769.6152491 | 13851.56455 |

| 3 | 20 | 587.435552 | 15665.73428 |

| 4 | 25 | 476.4717689 | 16472.41662 |

| 5 | 30 | 401.6075067 | 16880.6829 |

| 6 | 40 | 306.7195374 | 17225.27947 |

| 7 | 50 | 248.883506 | 17324.918 |

Table 2

Similarly, the exit velocity

| S.No. | |||

| 1 | 10 | 751.180072 | 14325.96107 |

| 2 | 15 | 513.0768327 | 16512.01299 |

| 3 | 20 | 391.6237013 | 17215.72099 |

| 4 | 25 | 317.6478459 | 17492.1388 |

| 5 | 30 | 267.7383378 | 17605.13749 |

| 6 | 40 | 204.4796916 | 17647.84143 |

| 7 | 50 | 165.9223374 | 17603.1453 |

Table 3

Refer Table 1, 2, and 3.

Plot the graph for the exit pressure

Refer Table 1, 2, and 3.

Plot the graph for the exit pressure

Want to see more full solutions like this?

Chapter 5 Solutions

THERMODYNAMICS (LL)-W/ACCESS >CUSTOM<

Additional Engineering Textbook Solutions

Vector Mechanics For Engineers

Mechanics of Materials (10th Edition)

BASIC BIOMECHANICS

Database Concepts (8th Edition)

Electric Circuits. (11th Edition)

Thermodynamics: An Engineering Approach

- Test for exactness. If exact, solve. If not, use an integrating factor as given or obtained by inspection or by the theorems in the text. a. 2xydx+x²dy = 0 b. (x2+y2)dx-2xydy = 0 c. 6xydx+5(y + x2)dy = 0arrow_forwardNewton's law of cooling. A thermometer, reading 5°C, is brought into a room whose temperature is 22°C. One minute later the thermometer reading is 12°C. How long does it take until the reading is practically 22°C, say, 21.9°C?arrow_forwardSolve a. y' + 2xy = ex-x² b. y' + y sin x = ecosx, y(0) = −1 y(0) = −2.5arrow_forward

- = MMB 241 Tutorial 3.pdf 2/6 90% + + 5. The boat is traveling along the circular path with a speed of v = (0.0625t²) m/s, where t is in seconds. Determine the magnitude of its acceleration when t = 10 s. 40 m v = 0.0625² 6. If the motorcycle has a deceleration of at = (0.001s) m/s² and its speed at position A is 25 m/s, determine the magnitude of its acceleration when it passes point B. .A 90° 300 m n B 2arrow_forward= MMB 241 Tutorial 3.pdf 4/6 67% + 9. The car is traveling along the road with a speed of v = (2 s) m/s, where s is in meters. Determine the magnitude of its acceleration when s = 10 m. v = (2s) m/s 50 m 10. The platform is rotating about the vertical axis such that at any instant its angular position is u = (4t 3/2) rad, where t is in seconds. A ball rolls outward along the radial groove so that its position is r = (0.1+³) m, where t is in seconds. Determine the magnitudes of the velocity and acceleration of the ball when t = 1.5s.arrow_forwardThe population of a certain country is known to increase at a rate proportional to the number of people presently living in the country. If after two years the population has doubled, and after three years the population is 20,000, estimate the number of people initially living in the country.arrow_forward

- = MMB 241 Tutorial 3.pdf 6/6 100% + | 日 13. The slotted link is pinned at O, and as a result of the constant angular velocity *= 3 rad/s it drives the peg P for a short distance along the spiral guide r = (0.40) m, where 0 is in radians. Determine the radial and transverse components of the velocity and acceleration of P at the instant = 1/3 rad. 0.5 m P r = 0.40 =3 rad/sarrow_forward= MMB 241 Tutorial 3.pdf 1/6 90% + DYNAMICS OF PARTICLES (MMB 241) Tutorial 3 Topic: Kinematics of Particles:- Path and Polar coordinate systems and general curvilinear QUESTIONS motion. 1. Determine the acceleration at s = 2 m if v = (2 s) m/s², where s is in meters. At s = 0, v = 1 m/s. 3 m 2. Determine the acceleration when t=1s if v = (4t2+2) m/s, where t is in seconds. v=(4²+2) m/s 6 marrow_forward5.112 A mounting bracket for electronic components is formed from sheet metal with a uniform thickness. Locate the center of gravity of the bracket. 0.75 in. 3 in. ༧ Fig. P5.112 1.25 in. 0.75 in. y r = 0.625 in. 2.5 in. 1 in. 6 in. xarrow_forward

- 4-105. Replace the force system acting on the beam by an equivalent resultant force and couple moment at point B. A 30 in. 4 in. 12 in. 16 in. B 30% 3 in. 10 in. 250 lb 260 lb 13 5 12 300 lbarrow_forwardSketch and Describe a hatch coaming and show how the hatch coamings are framed in to ships strucure?arrow_forwardSketch and describe hatch coamings. Describe structrual requirements to deck plating to compensate discontinuity for corners of a hatch. Show what is done to the deck plating when the decks are cut away and include the supporting members.arrow_forward

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY