International Edition---engineering Mechanics: Statics, 4th Edition

4th Edition

ISBN: 9781305501607

Author: Andrew Pytel And Jaan Kiusalaas

Publisher: CENGAGE L

expand_more

expand_more

format_list_bulleted

Concept explainers

Textbook Question

Chapter 5, Problem 5.7P

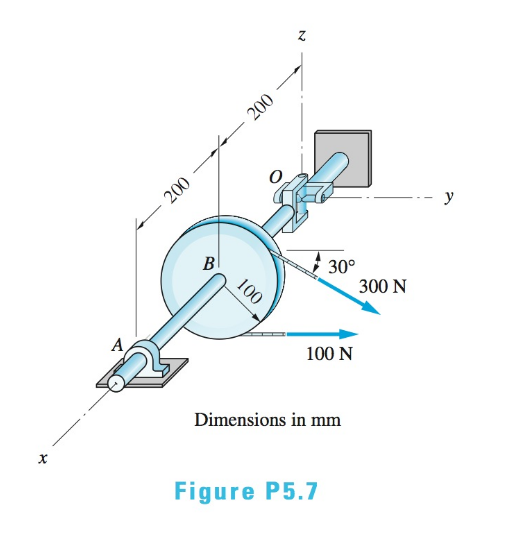

The shaft-pulley assembly is supported by the universal joint at O and by the slider hearing at A. The pulley, which has a mass of 7 kg, is subjected to the belt tensions shown. The mass of the shaft may be neglected. Draw an FBD that consists of the pulley and shaft AO. Determine the number of unknowns on this FBD.

Expert Solution & Answer

Trending nowThis is a popular solution!

Students have asked these similar questions

=

MMB 241 Tutorial 2.pdf

1 / 3

75%

+ +

Tutorial z

Topic: Kinematics of Particles:-.

QUESTIONS

1. Use the chain-rule and find y and ŷ in terms of x, x and x if

a) y=4x²

b) y=3e

c) y = 6 sin x

2. The particle travels from A to B. Identify the three unknowns, and write the three

equations needed to solve for them.

8 m

10 m/s

30°

B

x

3. The particle travels from A to B. Identify the three unknowns, and write the three

equations needed to solve for them.

A

40 m/s

20 m

B

1

3 m³/s-

1 md

45°

V

1.8 mr

2mr

=

MMB 241 Tutorial 2.pdf

3/3

75%

+ +

6. A particle is traveling along the parabolic path y = 0.25 x². If x = 8 m, vx=8 m/s, and ax=

4 m/s² when t = 2 s, determine the magnitude of the particle's velocity and acceleration at

this instant.

y = 0.25x²

-x

7. Determine the speed at which the basketball at A must be thrown at the angle of 30° so

that it makes it to the basket at B.

30°

-x

1.5 m

B

3 m

-10 m-

8. The basketball passed through the hoop even though it barely cleared the hands of the

player B who attempted to block it. Neglecting the size of the ball, determine the

2

Chapter 5 Solutions

International Edition---engineering Mechanics: Statics, 4th Edition

Ch. 5 - Bar AB of negligible weight is supported by a...Ch. 5 - Draw the FBD for the bar described in Prob. 5.1 if...Ch. 5 - The space truss ABCD in the shape of a tetrahedron...Ch. 5 - Draw the FBD of the portion BCD of the space truss...Ch. 5 - The homogeneous plate of weight W is supported by...Ch. 5 - The bar ABCD of negligible weight is supported by...Ch. 5 - The shaft-pulley assembly is supported by the...Ch. 5 - The 60-lb homogeneous door is supported by hinges...Ch. 5 - Draw the FBD for bar BCD. The connections at A and...Ch. 5 - The homogeneous 360-lb plate with a rectangular...

Ch. 5 - The L-shaped rod, supported by slider bearings at...Ch. 5 - The homogeneous 240-lb bar is supported by a rough...Ch. 5 - In Sample Problem 5.4, determine the tension TAC...Ch. 5 - In Sample Problem 5.5, compute the tension TAD...Ch. 5 - In Sample Problem 5.5, determine Oy with one...Ch. 5 - Determine the tension TB in Sample Problem 5.6...Ch. 5 - Compute the tension TAE in Sample Problem 5.7...Ch. 5 - The 80-lb homogeneous plate is suspended from four...Ch. 5 - The three bars are welded together to form a rigid...Ch. 5 - The compound bar is supported by a thrust bearing...Ch. 5 - The homogeneous 20-kg door is held in the...Ch. 5 - The light boom AB is attached to the vertical wall...Ch. 5 - The homogeneous 80-kg sign is suspended from a...Ch. 5 - The bar ABC is supported by a ball-and-socket at A...Ch. 5 - Determine the forces in members PAE,PAF, and PBG...Ch. 5 - The figure shows the FBD of a portion of the space...Ch. 5 - Calculate all forces acting on the bar AB...Ch. 5 - Determine the forces in members AD, BD, and CD of...Ch. 5 - Find the tension in cable BE that supports the bar...Ch. 5 - For the structure in Prob. 5.9, determine the...Ch. 5 - Calculate the reaction at D for the structure...Ch. 5 - Calculate the reaction at D for the structure...Ch. 5 - Determine the tension in each of the three ropes...Ch. 5 - Using only one equilibrium equation, compute the...Ch. 5 - The homogeneous 25-kg bar AB is supported by a...Ch. 5 - The shaft AB is supported by a thrust bearing at A...Ch. 5 - The bar ABCD has a built-in support at A....Ch. 5 - The total weight of the L-shaped beam of constant...Ch. 5 - The bent rod of negligible weight is supported by...Ch. 5 - A 120-lb weight is attached to the cable that is...Ch. 5 - Calculate the force in cable CD and the reaction...Ch. 5 - The 350-lb homogeneous plate has the shape of an...Ch. 5 - The bent rod ABCD is supported by a...Ch. 5 - A hoist is formed by connecting bars BD and BE to...Ch. 5 - The crank arm OD of the winch is connected by a...Ch. 5 - The 80-lb homogeneous plate is supported by a...Ch. 5 - The frame is built into the wall at D and G. The...Ch. 5 - The bent bar of negligible weight is supported by...Ch. 5 - Determine the reactions at ball-and-socket joints...Ch. 5 - The 180-lb homogeneous bar is supported by a...Ch. 5 - The bent rod is supported by a ball-and-socket...Ch. 5 - Find the maximum load P that can be supported by...Ch. 5 - The vertical mast OA, which weighs 1.5 kN, is...Ch. 5 - The homogeneous bar AB weighs 50-lb. End B leans...Ch. 5 - The 500-kg crate is supported by the three cables....Ch. 5 - The uniform bars AB and BC each weigh 4 lb/ft....Ch. 5 - The rigid body of negligible weight is supported...Ch. 5 - The homogeneous 860-kg bar AB is supported by a...Ch. 5 - The triangular plate is supported by three...Ch. 5 - The connections at the ends of bars AB and BC arc...Ch. 5 - The bar AEB is supported by a ball-and-socket...Ch. 5 - The shaft is supported by a thrust bearing at A...

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Adhesives distribute loads across the interface, whereas fasteners create areas of localized stresses. True or Falsearrow_forwardA continuous column flash system is separating 100 kmol/h of a saturated liquid feed that is 45 mol% methanol and 55 mol% water at 1.0 atm. Operate with L/V = 1.5 and the outlet bottoms at xN = 0.28. Find the values of FL, FV, y1, and the number of equilibrium stages required. Find the value of Q used to vaporize FV. For a normal flash with the same feed and the same V/F, find the values of x and y.arrow_forwardA beer still is being used to separate ethanol from water at 1.0 atm. The saturated liquid feed flow rate is F = 840.0 kmol/h. The feed is 44.0 mol% ethanol. The saturated vapor steam is pure water with ratio of steam flow rate S to feed rate, S/F = 2/3. We desire a bottoms product that is 4.0 mol% ethanol. CMO is valid. Find the mole fraction of ethanol in the distillate vapor, yD,E. Find the number of equilibrium stages required. If the feed is unchanged and the S/F ratio is unchanged, but the number of stages is increased to a very large number, what is the lowest bottoms mole fraction of ethanol that can be obtained?arrow_forward

- 3.1 Convert the following base-2 numbers to base-10: (a) 1011001, (b) 110.0101, and (c) 0.01011.arrow_forwardConsider the forces acting on the handle of the wrench in (Figure 1). a) Determine the moment of force F1={−F1={−2i+i+ 4 jj −−8k}lbk}lb about the zz axis. Express your answer in pound-inches to three significant figures. b) Determine the moment of force F2={F2={3i+i+ 7 jj −−6k}lbk}lb about the zz axis. Express your answer in pound-inches to three significant figures.arrow_forwardI need you to explain each and every step (Use paper)arrow_forward

- Calculate the Moment About the Point A -20"- 5 lb 40 N D 1.5 m 40 N 4.5 m A 15 lb. 150 mm 52 N 5 12 100 mm 15 lb. 26 lb. 12 5 34 lb. 13 8 15 77777 36 lb.arrow_forwardCalculate the Moment About the Point A -20"- 5 lb 40 N D 1.5 m 40 N 4.5 m A 15 lb. 150 mm 52 N 5 12 100 mm 15 lb. 26 lb. 12 5 34 lb. 13 8 15 77777 36 lb.arrow_forwardFormala for Hunzontal component= + cos & Vertical Component: Fsin t Find the vertical and horizontal components for the figure bellow: 30° 200 N 77 200 cos 30 = 173 N // 200 sin 30 = 100 N YA a₂+b₂ b₂ (b₁,b₂) a+b 20haits (a+b₁,a+b) Magnitude a and b a = lbl = 2o unite rugle of vector a wt Horisontal Axis = 30 11 vector & wt Honzontal Axis - 60° b b a= |a| Cas 30 a2 (a1, a2) ag = 10 bx = /b/ cos a 1 20 cos 80 = 17.32 Sia 30 = 20 sin 30. 60 = 10 = 20 Cos 60 = It by = 161 sin 60 = 20 sia 60 = 17.32 b₁ Rx ax +bx = 17.32 +10=2732 a₁ a₁+b₁ X By = ou + by= + + by = 10 + 17.32 =27.32 Magnitude = 38.637 Find the Vector a +b the Resultans The angle of the vector with the horizontal axle is 30 degrees while the angle of the vector b is 60 degrees. The magnitude of both vectors is 20 (units) angle of the Resultant vector = tam- " (14) 45arrow_forward

- The net force exerted on the piston by the exploding fuel-air mixture and friction is 5 kN to the left. A clockwise couple M = 200 N-m acts on the crank AB. The moment of inertia of the crank about A is 0.0003 kg-m2 . The mass of the connecting rod BC is 0.36 kg, and its center of mass is 40 mm from B on the line from B to C. The connecting rod’s moment of inertia about its center of mass is 0.0004 kg-m2 . The mass of the piston is 4.6 kg. The crank AB has a counterclockwise angular velocity of 2000 rpm at the instant shown. Neglect the gravitational forces on the crank, connecting rod, and piston – they still have mass, just don’t include weight on the FBDs. What is the piston’s acceleration?arrow_forwardSolve only no 1 calculations,the one with diagram,I need handwritten expert solutionsarrow_forwardProblem 3 • Compute the coefficient matrix and the right-hand side of the n-parameter Ritz approximation of the equation d du (1+x)· = 0 for 0 < x < 1 dx dx u (0) = 0, u(1) = 1 Use algebraic polynomials for the approximation functions. Specialize your result for n = 2 and compute the Ritz coefficients.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

International Edition---engineering Mechanics: St...Mechanical EngineeringISBN:9781305501607Author:Andrew Pytel And Jaan KiusalaasPublisher:CENGAGE L

International Edition---engineering Mechanics: St...Mechanical EngineeringISBN:9781305501607Author:Andrew Pytel And Jaan KiusalaasPublisher:CENGAGE L

International Edition---engineering Mechanics: St...

Mechanical Engineering

ISBN:9781305501607

Author:Andrew Pytel And Jaan Kiusalaas

Publisher:CENGAGE L

EVERYTHING on Axial Loading Normal Stress in 10 MINUTES - Mechanics of Materials; Author: Less Boring Lectures;https://www.youtube.com/watch?v=jQ-fNqZWrNg;License: Standard YouTube License, CC-BY