Materials for Civil and Construction Engineers (4th Edition)

4th Edition

ISBN: 9780134320533

Author: Michael S. Mamlouk, John P. Zaniewski

Publisher: PEARSON

expand_more

expand_more

format_list_bulleted

Textbook Question

thumb_up100%

Chapter 5, Problem 5.29QP

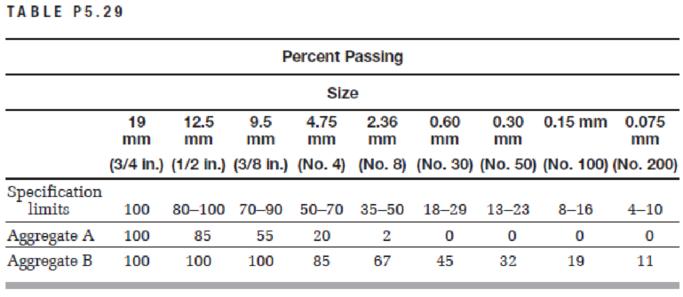

Table P5.29 shows the grain size distribution for two aggregates and the specification limits for an asphalt concrete. Determine the blend proportion required to meet the specification and the gradations of the blend. On a semilog gradation graph, plot the gradations of aggregate A, aggregate B, the selected blend, and the specification limits.

Expert Solution & Answer

Trending nowThis is a popular solution!

Students have asked these similar questions

Table shows the grain size distribution for two aggregates and the specification limits for an asphalt concrete. Determine the blend proportion requiredto meet the specification and the gradations of the blend. On a semilog gradation graph, plot the gradations of aggregate A, aggregate B, the selected blend,and the specification limits.c

Table shows the grain size distribution for two aggregates and the specification limits for an asphalt concrete. Determine the blend proportion required to meet the specification and the gradations of the blend. On a semilog gradation graph, plot the gradations of aggregate A, aggregate B, the selected blend,and the specification limits.

Based on the data shown in Table P9.31, select the blend for a Superpave

design aggregate structure. Assume <0.3 million ESAL and 19 mm nominal

maximum aggregate size.

TABLE P9.31

Blend

Data

1

3

Gmb

Gmm

2.451

2.465

2.467

2.585

2.654

2.584

Gp

1.030

1.030

1.030

P

5.9

5.5

5.8

94.1

94.5

94.2

Ра

4.5

4.5

4.5

Gşb

2.657

2.667

2.705

Hini

127

135

124

Håes

113

114

118

Chapter 5 Solutions

Materials for Civil and Construction Engineers (4th Edition)

Ch. 5 - Prob. 5.1QPCh. 5 - Discuss five different desirable characteristics...Ch. 5 - Discuss five different desirable characteristics...Ch. 5 - The shape and surface texture of aggregate...Ch. 5 - Define the following terms: a. Saturated...Ch. 5 - Three samples of fine aggregate have the...Ch. 5 - A sample of wet aggregate weighed 297.2 N. After...Ch. 5 - 46.5 kg (102.3 lb) of fine aggregate is mixed with...Ch. 5 - Samples of coarse aggregate from a stockpile are...Ch. 5 - Base course aggregate has a target dry density of...

Ch. 5 - Calculate the percent voids between aggregate...Ch. 5 - Calculate the percent voids between aggregate...Ch. 5 - Coarse aggregate is placed in a rigid bucket and...Ch. 5 - The following laboratory tests are performed on...Ch. 5 - Students in the materials lab performed the...Ch. 5 - The specific gravity and absorption test (ASTM...Ch. 5 - Prob. 5.18QPCh. 5 - Calculate the sieve analysis shown in Table P5.19...Ch. 5 - Calculate the sieve analysis shown in Table P5.20,...Ch. 5 - A sieve analysis test was performed on a sample of...Ch. 5 - A sieve analysis test was performed on a sample of...Ch. 5 - Draw a graph to show the cumulative percent...Ch. 5 - Referring to Table 5.6, plot the specification...Ch. 5 - Referring to the aggregate gradations A, B, and C...Ch. 5 - Table P5.26 shows the grain size distributions of...Ch. 5 - Table P5.27 shows the grain size distributions of...Ch. 5 - Three aggregates are to be mixed together in the...Ch. 5 - Table P5.29 shows the grain size distribution for...Ch. 5 - Laboratory specific gravity and absorption tests...Ch. 5 - Table P5.31 shows the grain size distribution for...Ch. 5 - Prob. 5.32QPCh. 5 - Laboratory specific gravity and absorption tests...Ch. 5 - Prob. 5.34QPCh. 5 - Define the fineness modulus of aggregate. What is...Ch. 5 - Calculate the fineness modulus of aggregate A in...Ch. 5 - Calculate the fineness modulus of aggregate B in...Ch. 5 - A portland cement concrete mix requires mixing...Ch. 5 - Discuss the effect of the amount of material...Ch. 5 - Aggregates from three sources having the...Ch. 5 - Aggregates from three sources having the...Ch. 5 - A contractor is considering using three stockpiles...Ch. 5 - Prob. 5.43QPCh. 5 - What are the typical deleterious substances in...Ch. 5 - Review ASTM D75 and summarize the following: a....

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, civil-engineering and related others by exploring similar questions and additional content below.Similar questions

- Given four different types of aggregates to be used to produce a blended aggregate for use in the manufacture of asphaltic concrete, determine the bulk specific gravity of the aggregate mix.arrow_forwardQuestions 30 is based on the information below: An asphalt concrete mix design has the following properties. The densities of the binder and aggregate are 1.090 g/cm³ and 2.760 g/cm³, respectively. The bulk density of the entire mix is 2.220 g/cm³. The percent binder content is 6.2% (by weight). Assume no absorption. V₁= 1.0 cm³ Volume Vv Vb Vs AIR Binder Aggregate Mass Mb Ms Mt 30. As an engineer, you are asked to use this mix design for a 25 kilometer-long section of roadway where the total pavement width is 8.0 meters and the thickness is 15 centimeters. What is the (a) total volume of binder and (b) the total volume of aggregate that you would need to purchase? Also, determine the (c) total %air voids in the mix.arrow_forwardTable below shows the sieve analysis test result for aggregates A and B and the specification limits for an asphalt concrete. Determine the blend proportion required to meet the specification and the graduations of the blend. On a semi-log gradation graph, plot the gradations of aggregate A, aggregate B, the selected blend, and the specification limits in a same graph (you can use Excel sheets or you can draw the graphs on a semi-log attached to page 3 of this assignment). 19 12.5 9.5 4.75 2.36 0.60 0.30 0.15 Specification limit 100 80-100 70-90 50-70 35-50 18-29 13-23 8-16 Aggregate A 100 90 45 35 12 10 3 0 Aggregate B 100 100 100 80 77 45 32 18 Percentage passing % 0.001 0.01 0.1 1 10 100 Sieve Size (mm)arrow_forward

- 2 - show complete solutionarrow_forwardThe mix design for an asphalt concrete mixture requires 2 to 6% minus 0.075 mm. The three aggregates shown in Table P.5.34 are available. TABLE P5.34 Minus 0.075 mm Coarse 0.5% Intermediate 1.5% Fine Aggregate 11.5% Considering that approximately equal amounts of coarse and intermediate aggregate will be used in the mix, what is the percentage of fine aggregate that will give a resulting minus 0.075 mm in the mixture in the middle of the range, about 4%?arrow_forwardMax specific gravity of mixture = 2.48 and following details are given. Bulk specific gravity aggregates in the mix and asphalt absorbed (%) are respectively, Material Specific gravity Mix Composition Asphalt Cement 1.02 6.40 Coarse Aggregate 2.51 52.35 Fine Aggregate 2.74 33.45 Mineral filler 2.69 7.80 2.603 and 3.10 2.538 and 2.60 2.603 and 2.08 2.538 and 3.20arrow_forward

- A portland cement concrete mix requires mixing sand having a gradation following the midpoint of the ASTM gradation band and gravel having a gradation following the midpoint of size number 467 of the ASTM gradation band at a ratio of 2:3 by weight. On a 0.45 power gradation chart, plot the gradations of the sand, gravel, and the blend. Is the gradation of the blend well graded? If not, what would you call it?arrow_forwardAnswer 5.29arrow_forwardA portland cement concrete mix requires mixing sand having a gradationfollowing the midpoint of the ASTM gradation band (Table 5.4) and gravelhaving a gradation following the midpoint of size number 467 of the ASTMgradation band (Table 5.5) at a ratio of 2:3 by weight. On a 0.45 power gradation chart, plot the gradations of the sand, gravel, and the blend. Is the gradation of the blend well graded? If not, what would you call it?arrow_forward

- Table P5.29 shows the grain size distribution for two aggregates and the specifi- cation limits for an asphalt concrete. Determine the blend proportion required to meet the specification and the gradations of the blend. On a semilog grada- tion graph, plot the gradations of aggregate A, aggregate B, the selected blend, and the specification limits. TABLE P5.29 Percent Passing Sieve Size, mm 19 12.5 9.5 4.75 2.36 0.60 0.30 0.15 0.075 Specification limits 100 80–100 70-90 50-70 35-50 18–29 13-23 8-16 4-10 Aggregate A 100 85 20 2 55 Aggregate B 100 100 100 85 67 45 32 19 11arrow_forwardPlease provide complete solution.arrow_forwardThere are two sources of aggregates (A, B). A sample has been taken from both sources and measured their mass as shown in table below. Measurement Wet mass (9) Oven-dry mass (g) Aggregate A 500 480 Aggregate B 600 564 (a) Determine the total moisture content for the samples from both aggregate sources, respectively. (b) Determine the total moisture content for an aggregate blend with 30% of aggregate A and 70% of aggregate B.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning

Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning

Traffic and Highway Engineering

Civil Engineering

ISBN:9781305156241

Author:Garber, Nicholas J.

Publisher:Cengage Learning

Aggregates: Properties; Author: nptelhrd;https://www.youtube.com/watch?v=49yGZYeokKM;License: Standard YouTube License, CC-BY