John Patrick has recently been hired as controller of Valdosta Vinyl Company (VVC), a manufacturer of vinyl siding used in residential construction. VVC has been in the vinyl siding business for many years and is currently investigating ways to modernize its manufacturing process. At the first staff meeting Patrick attended. Jack Kielshesky, chief engineer, presented a proposal for automating the Molding Department. Kielshesky recommended that the company purchase two robots that would have the capability of replacing the eight direct-labor employees in the department. The cost savings outlined in the proposal include the elimination of direct-labor cost in the Molding Department plus a reduction of

Kielshesky responded by saying “I’m an engineer, not an accountant. But if we’re charging overhead on the basis of direct labor, and we eliminate the labor, then we eliminate the overhead.”

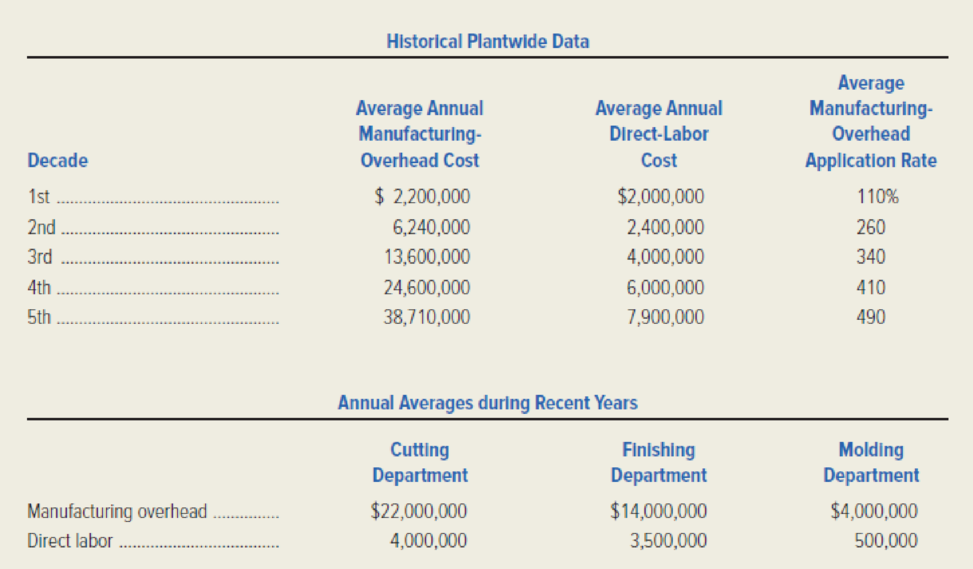

Patrick agreed with the president. He explained that as firms become more automated, they should rethink their product-costing systems. The president then asked Patrick to look into the matter and prepare a report for the next staff meeting. Patrick gathered the following data on the manufacturing-overhead rates experienced by VVC over the years. Patrick also wanted to have some departmental data to present at the meeting and, by using VVC’s accounting records, he was able to estimate the following annual averages for each manufacturing department over the five decades since VVC’s formation.

Required:

- 1. Disregarding the proposed use of robots in the Molding Department, describe the shortcomings of the system for applying overhead that is currently used by Valdosta Vinyl Company.

- 2. Explain the misconceptions underlying Kielshesky’s statement that the manufacturing-overhead cost in the Molding Department will be reduced to zero if the automation proposal is implemented.

- 3. Recommend ways to improve VVC’s method for applying overhead by describing how it should revise its product-costing system for each of the following departments:

- a. In the Cutting and Finishing Departments.

- b. To accommodate automation in the Molding Department.

Want to see the full answer?

Check out a sample textbook solution

Chapter 5 Solutions

Managerial Accounting: Creating Value in a Dynamic Business Environment

- I want to this question answer general accountingarrow_forwardProvide Answerarrow_forwardTremont Global, Inc. produces and sells a single product. The product sells for $175.00 per unit, and its variable expense is $52.50 per unit. The company's monthly fixed expense is $245,600. What is the monthly break-even in total dollar sales?arrow_forward

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning