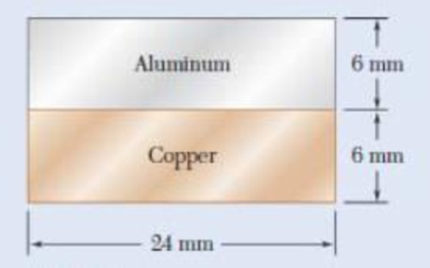

4.39 and 4.40 A copper strip (Ec = 105 GPa) and an aluminum strip (Ea = 75 GPa) are bonded together to form the composite beam shown. Knowing that the beam is bent about a horizontal axis by a couple of moment M = 35 N·m, determine the maximum stress in (a) the aluminum strip, (b) the copper strip.

Fig. P4.39

(a)

Find the maximum stress in the aluminum strip.

Answer to Problem 39P

The maximum stress in the aluminum strip is

Explanation of Solution

Given information:

The modulus of elasticity

The modulus of elasticity

The moment (M) in the beam is

Calculation:

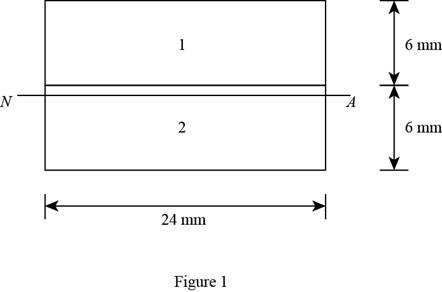

Show the cross-section of the composite bar as shown in Figure 1.

Refer Figure 1.

Consider the Copper and Aluminum is represented by rectangle 2 and 1.

The width and depth of the rectangle 1 are

The width and depth of the rectangle 2 are

Consider Aluminum as the reference material, then the value of

Calculate the ratio

Substitute

Calculate the distance (

Here,

The value of

Substitute

Consider the entire cross-section of the composite bar is transformed into Aluminum.

Calculate the moment of inertia

Substitute

Calculate the moment of inertia

Substitute

Calculate the moment of inertia of the transformed cross-section using the relation:

Substitute

Calculate the maximum stress (

Calculate the maximum stress for Aluminum strip as follows:

Substitute

Thus, the maximum stress in the aluminum strip is

(b)

Find the maximum stress in the aluminum strip.

Answer to Problem 39P

The maximum stress in the aluminum strip is

Explanation of Solution

Given information:

The modulus of elasticity

The modulus of elasticity

The moment (M) in the beam is

Calculation:

Calculate the maximum stress for Copper strip as follows:

Substitute

Thus, the maximum stress in the copper strip is

Want to see more full solutions like this?

Chapter 4 Solutions

EBK MECHANICS OF MATERIALS

- PROBLEM 3.46 The solid cylindrical rod BC of length L = 600 mm is attached to the rigid lever AB of length a = 380 mm and to the support at C. When a 500 N force P is applied at A, design specifications require that the displacement of A not exceed 25 mm when a 500 N force P is applied at A For the material indicated determine the required diameter of the rod. Aluminium: Tall = 65 MPa, G = 27 GPa. Aarrow_forwardFind the equivalent mass of the rocker arm assembly with respect to the x coordinate. k₁ mi m2 k₁arrow_forward2. Figure below shows a U-tube manometer open at both ends and containing a column of liquid mercury of length l and specific weight y. Considering a small displacement x of the manometer meniscus from its equilibrium position (or datum), determine the equivalent spring constant associated with the restoring force. Datum Area, Aarrow_forward

- 1. The consequences of a head-on collision of two automobiles can be studied by considering the impact of the automobile on a barrier, as shown in figure below. Construct a mathematical model (i.e., draw the diagram) by considering the masses of the automobile body, engine, transmission, and suspension and the elasticity of the bumpers, radiator, sheet metal body, driveline, and engine mounts.arrow_forward3.) 15.40 – Collar B moves up at constant velocity vB = 1.5 m/s. Rod AB has length = 1.2 m. The incline is at angle = 25°. Compute an expression for the angular velocity of rod AB, ė and the velocity of end A of the rod (✓✓) as a function of v₂,1,0,0. Then compute numerical answers for ȧ & y_ with 0 = 50°.arrow_forward2.) 15.12 The assembly shown consists of the straight rod ABC which passes through and is welded to the grectangular plate DEFH. The assembly rotates about the axis AC with a constant angular velocity of 9 rad/s. Knowing that the motion when viewed from C is counterclockwise, determine the velocity and acceleration of corner F.arrow_forward

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY