Managerial Accounting

15th Edition

ISBN: 9781337912020

Author: Carl Warren, Ph.d. Cma William B. Tayler

Publisher: South-Western College Pub

expand_more

expand_more

format_list_bulleted

Concept explainers

Textbook Question

Chapter 4, Problem 1PA

Gwinnett County Chrome Company manufactures three chrome-plated products—automobile bumpers, valve covers, and wheels. These products are manufactured in two production departments (Stamping and Plating). The factory

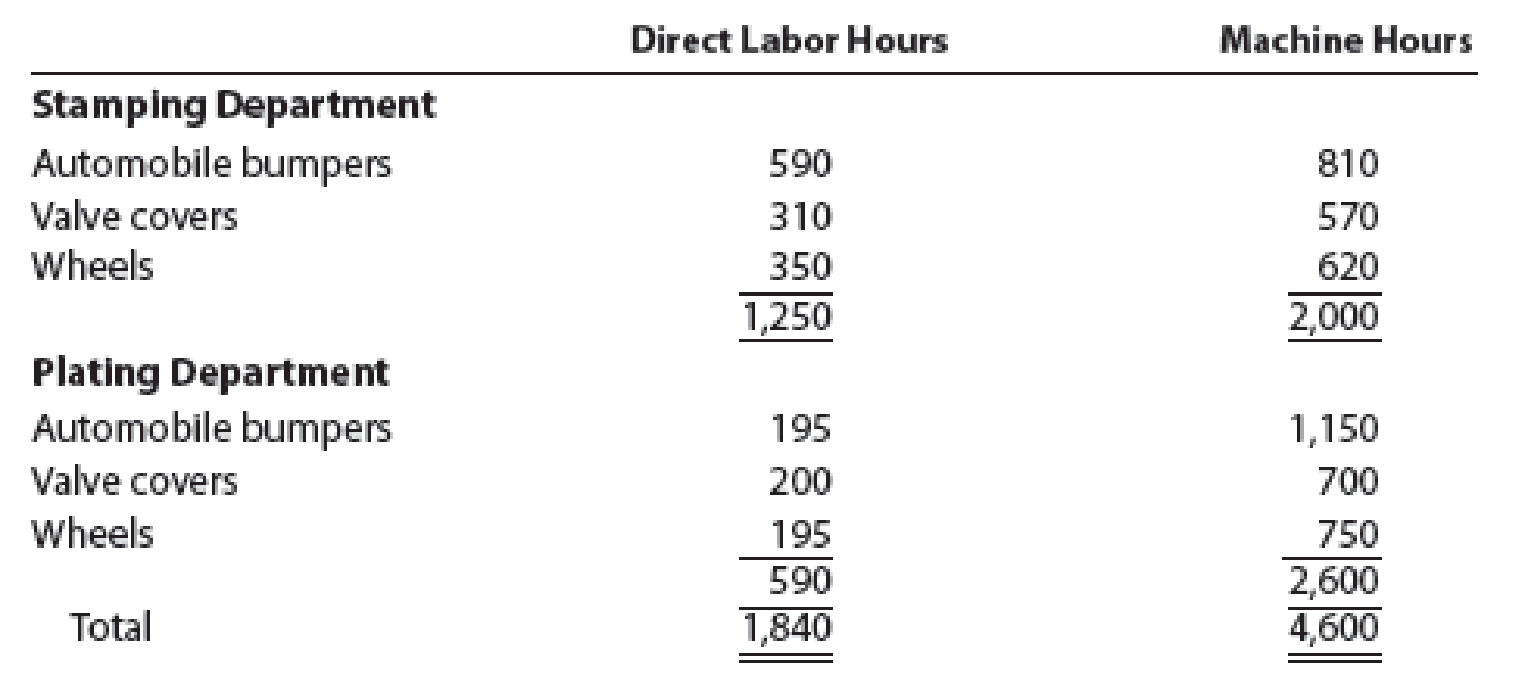

The three products consume both machine hours and direct labor hours in the two production departments as follows:

Instructions

- 1. Determine the single plantwide factory overhead rate, using each of the following allocation bases: (a) direct labor hours and (b) machine hours.

- 2. Determine the product

factory overhead costs , using (a) the direct labor hour plantwide factory overhead rate and (b) the machine hour plantwide factory overhead rate.

Expert Solution & Answer

Want to see the full answer?

Check out a sample textbook solution

Students have asked these similar questions

Can you help me solve this general accounting problem using the correct accounting process?

I need help finding the accurate solution to this financial accounting problem with valid methods.

Please provide the correct answer to this general accounting problem using valid calculations.

Chapter 4 Solutions

Managerial Accounting

Ch. 4 - Why would management be concerned about the...Ch. 4 - Why would a manufacturing company with multiple...Ch. 4 - Prob. 3DQCh. 4 - Prob. 4DQCh. 4 - How does activity-based costing differ from the...Ch. 4 - Prob. 6DQCh. 4 - Prob. 7DQCh. 4 - Under what circumstances might the activity-based...Ch. 4 - Prob. 9DQCh. 4 - Prob. 10DQ

Ch. 4 - Single plantwide factory overhead rate The total...Ch. 4 - Multiple production department factory overhead...Ch. 4 - Activity-based costing: factory overhead costs The...Ch. 4 - Activity-based costing: selling and administrative...Ch. 4 - Activity-based costing for a service business...Ch. 4 - Kennedy Appliance Inc.s Machining Department...Ch. 4 - Bach Instruments Inc. makes three musical...Ch. 4 - Scrumptious Snacks Inc. manufactures three types...Ch. 4 - Isaac Engines Inc. produces three productspistons,...Ch. 4 - Handy Leather, Inc., produces three sizes of...Ch. 4 - Eclipse Motor Company manufactures two types of...Ch. 4 - The management of Nova Industries Inc....Ch. 4 - Comfort Foods Inc. uses activity-based costing to...Ch. 4 - Nozama.com Inc. sells consumer electronics over...Ch. 4 - Hercules Inc. manufactures elliptical exercise...Ch. 4 - Lonsdale Inc. manufactures entry and dining room...Ch. 4 - Activity cost pools, activity rates, and product...Ch. 4 - Handbrain Inc. is considering a change to...Ch. 4 - Prob. 14ECh. 4 - Activity-based costing and product cost distortion...Ch. 4 - Prob. 16ECh. 4 - Evaluating selling and administrative cost...Ch. 4 - Prob. 18ECh. 4 - Prob. 19ECh. 4 - Activity-based costing for a service company...Ch. 4 - Bounce Back Insurance Company carries three major...Ch. 4 - Gwinnett County Chrome Company manufactures three...Ch. 4 - The management of Gwinnett County Chrome Company,...Ch. 4 - Activity-based and department rate product costing...Ch. 4 - Activity-based product costing Mello Manufacturing...Ch. 4 - Allocating selling and administrative expenses...Ch. 4 - Product costing and decision analysis for a...Ch. 4 - Single plantwide factory overhead rate Spotted Cow...Ch. 4 - Multiple production department factory overhead...Ch. 4 - Activity-based department rate product costing and...Ch. 4 - Activity-based product costing Sweet Sugar Company...Ch. 4 - Allocating selling and administrative expenses...Ch. 4 - Product costing and decision analysis for a...Ch. 4 - Life Force Fitness, Inc., assembles and sells...Ch. 4 - Prob. 2MADCh. 4 - Prob. 3MADCh. 4 - Production run size and activity improvement...Ch. 4 - Prob. 5MADCh. 4 - Ethics in Action The controller of Tri Con Global...Ch. 4 - Communication The controller of New Wave Sounds...Ch. 4 - Pelder Products Company manufactures two types of...Ch. 4 - The Chocolate Baker specializes in chocolate baked...Ch. 4 - Young Company is beginning operations and is...Ch. 4 - Cynthia Rogers, the cost accountant for Sanford...

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, accounting and related others by exploring similar questions and additional content below.Similar questions

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Managerial AccountingAccountingISBN:9781337912020Author:Carl Warren, Ph.d. Cma William B. TaylerPublisher:South-Western College Pub

Managerial AccountingAccountingISBN:9781337912020Author:Carl Warren, Ph.d. Cma William B. TaylerPublisher:South-Western College Pub Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage LearningPrinciples of Accounting Volume 2AccountingISBN:9781947172609Author:OpenStaxPublisher:OpenStax College

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage LearningPrinciples of Accounting Volume 2AccountingISBN:9781947172609Author:OpenStaxPublisher:OpenStax College Financial And Managerial AccountingAccountingISBN:9781337902663Author:WARREN, Carl S.Publisher:Cengage Learning,

Financial And Managerial AccountingAccountingISBN:9781337902663Author:WARREN, Carl S.Publisher:Cengage Learning, Principles of Cost AccountingAccountingISBN:9781305087408Author:Edward J. Vanderbeck, Maria R. MitchellPublisher:Cengage Learning

Principles of Cost AccountingAccountingISBN:9781305087408Author:Edward J. Vanderbeck, Maria R. MitchellPublisher:Cengage Learning

Managerial Accounting

Accounting

ISBN:9781337912020

Author:Carl Warren, Ph.d. Cma William B. Tayler

Publisher:South-Western College Pub

Cornerstones of Cost Management (Cornerstones Ser...

Accounting

ISBN:9781305970663

Author:Don R. Hansen, Maryanne M. Mowen

Publisher:Cengage Learning

Principles of Accounting Volume 2

Accounting

ISBN:9781947172609

Author:OpenStax

Publisher:OpenStax College

Financial And Managerial Accounting

Accounting

ISBN:9781337902663

Author:WARREN, Carl S.

Publisher:Cengage Learning,

Principles of Cost Accounting

Accounting

ISBN:9781305087408

Author:Edward J. Vanderbeck, Maria R. Mitchell

Publisher:Cengage Learning

What is Cost Allocation? Definition & Process; Author: FloQast;https://www.youtube.com/watch?v=hLhvvHvZ3JM;License: Standard Youtube License