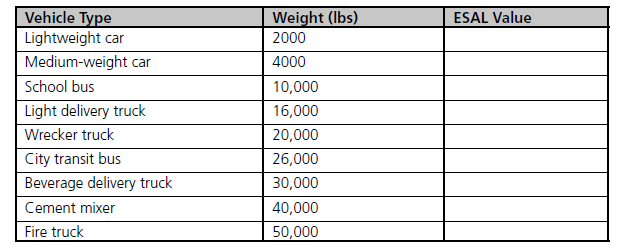

(Transportation) Road construction requires estimating the expected loads on a road’s pavement over its design life. A common approach for determining this information is to use ESAL values; one ESAL is the load a single 18,000-lb (80,000 N) single-axle truck applies to the road’s surface. The ESAL value for any single-axle vehicle can be approximated by this formula:

ESAL is the equivalent single-axle load.

W is the vehicle’s weight (lbs).

Using this formula, write, compile, and run a C++

Want to see the full answer?

Check out a sample textbook solution

Chapter 3 Solutions

C++ for Engineers and Scientists

- I want a picture of the tools and the pictures used Cisco Packet Tracer Smart Home Automation:o Connect a temperature sensor and a fan to a home gateway.o Configure the home gateway so that the fan is activated when the temperature exceedsa set threshold (e.g., 30°C).2. WiFi Network Configuration:o Set up a wireless LAN with a unique SSID.o Enable WPA2 encryption to secure the WiFi network.o Implement MAC address filtering to allow only specific clients to connect.3. WLC Configuration:o Deploy at least two wireless access points connected to a Wireless LAN Controller(WLC).o Configure the WLC to manage the APs, broadcast the configured SSID, and applyconsistent security settings across all APs.arrow_forwardA. What will be printed executing the code above?B. What is the simplest way to set a variable of the class Full_Date to January 26 2020?C. Are there any empty constructors in this class Full_Date?a. If there is(are) in which code line(s)?b. If there is not, how would an empty constructor be? (create the code lines for it)D. Can the command std::cout << d1.m << std::endl; be included after line 28 withoutcausing an error?a. If it can, what will be printed?b. If it cannot, how could this command be fixed?arrow_forwardCisco Packet Tracer Smart Home Automation:o Connect a temperature sensor and a fan to a home gateway.o Configure the home gateway so that the fan is activated when the temperature exceedsa set threshold (e.g., 30°C).2. WiFi Network Configuration:o Set up a wireless LAN with a unique SSID.o Enable WPA2 encryption to secure the WiFi network.o Implement MAC address filtering to allow only specific clients to connect.3. WLC Configuration:o Deploy at least two wireless access points connected to a Wireless LAN Controller(WLC).o Configure the WLC to manage the APs, broadcast the configured SSID, and applyconsistent security settings across all APs.arrow_forward

- Transform the TM below that accepts words over the alphabet Σ= {a, b} with an even number of a's and b's in order that the output tape head is positioned over the first letter of the input, if the word is accepted, and all letters a should be replaced by the letter x. For example, for the input aabbaa the tape and head at the end should be: [x]xbbxx z/z,R b/b,R F ① a/a,R b/b,R a/a, R a/a,R b/b.R K a/a,R L b/b,Rarrow_forwardGiven the C++ code below, create a TM that performs the same operation, i.e., given an input over the alphabet Σ= {a, b} it prints the number of letters b in binary. 1 #include 2 #include 3 4- int main() { std::cout > str; for (char c : str) { if (c == 'b') count++; 5 std::string str; 6 int count = 0; 7 char buffer [1000]; 8 9 10 11- 12 13 14 } 15 16- 17 18 19 } 20 21 22} std::string binary while (count > 0) { binary = std::to_string(count % 2) + binary; count /= 2; std::cout << binary << std::endl; return 0;arrow_forwardConsidering the CFG described below, answer the following questions. Σ = {a, b} • NT = {S} Productions: P1 S⇒aSa P2 P3 SbSb S⇒ a P4 S⇒ b A. List one sequence of productions that can accept the word abaaaba; B. Give three 5-letter words that can be accepted by this CFG; C. Create a Pushdown automaton capable of accepting the language accepted by this CFG.arrow_forward

- Given the FSA below, answer the following questions. b 1 3 a a b b с 2 A. Write a RegEx that is equivalent to this FSA as it is; B. Write a RegEx that is equivalent to this FSA removing the states and edges corresponding to the letter c. Note: To both items feel free to use any method you want, including analyzing which words are accepted by the FSA, to generate your RegEx.arrow_forward3) Finite State Automata Given the FSA below, answer the following questions. a b a b 0 1 2 b b 3 A. Give three 4-letter words that can be accepted by this FSA; B. Give three 4-letter words that cannot be accepted by this FSA; C. How could you describe the words accepted by this FSA? D. Is this FSA deterministic or non-deterministic?arrow_forwardConsidering the TM below, answer the following questions. a/x,R €/E,L €/E,R €/E,L x/E,R c/c,R b/E.L c/c,L x/x,R I J K L M F b/E.L D A. Give three 4-letter words that can be accepted by this TM; B. Give three 4-letter words that cannot be accepted by this TM; C. How could you describe the words accepted by this TM? D. What is the alphabet of the language accepted by this TM?arrow_forward

- What is the generator? Explain motor generator motorarrow_forwardThis battle room is focused on entry level tasks for a network analyst where you will be given trials and reconnaissance, sensor tuning, log aggregation, SIEM queries, and network analysis. For this week’s project, complete the following tasks: From your Project Ares portal, LOG IN Click on LAUNCH GAME. Select the region NORTH AMERICA Click on Battle School Under the BATTLE SCHOOL pop-up window, click on START TRAINING. Under the BATTLE ROOMS tile, click on ENTER. Under the NETWORK ANALYST tile, click on PLAY. Wait for the Battle Room to load. While loading, the BATTLE ROOM button will display red. Once the Battle Room is loaded, the BATTLE ROOM button will turn yellow and the center of the disk display will indicate CONNECTED. Click on the BATTLE ROOM button to enter the Battle Room. Below the TASKS folder, make sure you click on INSTRUCTIONS to download the Network Analyst Fundamentals material. In the Battle Room, under the TASKS menu select task INTRUSION DETECTION. Complete…arrow_forwardCreate a relationship between the common field (Technician Number) of the two tables. Make sure that each client must have 1 and only 1 technician assigned, and each technician can have multiple clients. 2. Create a query to show the Client Number, Client Name, Billed, Paid for clients in Anderson city. Save the query. 3. Create a query to show the Technician Number, Last Name, First Name, YTD Earnings for technicians whose Hourly Rate is greater than or equal to 30. Save the query. 4. Create a query to show Client Number, Client Name, Billed, Paid for clients whose technician number is 22 and whose Billed is over 300. Save the query. 5. Create a query to show the Technician Number, Last Name, First Name, Client Number, Client Name for clients whose technician number 23. Save the query. 6. Create a query to show the Technician Number, Last Name, First Name, Client Number, Client Name for clients whose technician number 23 or 29. Save the query Help please Microsoft office accessarrow_forward

C++ for Engineers and ScientistsComputer ScienceISBN:9781133187844Author:Bronson, Gary J.Publisher:Course Technology Ptr

C++ for Engineers and ScientistsComputer ScienceISBN:9781133187844Author:Bronson, Gary J.Publisher:Course Technology Ptr C++ Programming: From Problem Analysis to Program...Computer ScienceISBN:9781337102087Author:D. S. MalikPublisher:Cengage Learning

C++ Programming: From Problem Analysis to Program...Computer ScienceISBN:9781337102087Author:D. S. MalikPublisher:Cengage Learning Operations Research : Applications and AlgorithmsComputer ScienceISBN:9780534380588Author:Wayne L. WinstonPublisher:Brooks Cole

Operations Research : Applications and AlgorithmsComputer ScienceISBN:9780534380588Author:Wayne L. WinstonPublisher:Brooks Cole