(a)

Interpretation:

For the given alloy, an artificial age-hardening heat treatment needs to be recommended.

Concept Introduction:

The mixture of magnesium with other elements is known as magnesium alloy. The other elements include Zinc, Manganese, Aluminum and Copper.

Solidification takes place after complete mixing. It gets phase transformation to Liquid phase and there is no diffusion in the solid phase. With a decrease in the temperature of aluminum, the solubility of aluminium in magnesium also decreases.

If temperature is increased above,

Answer to Problem 12.30P

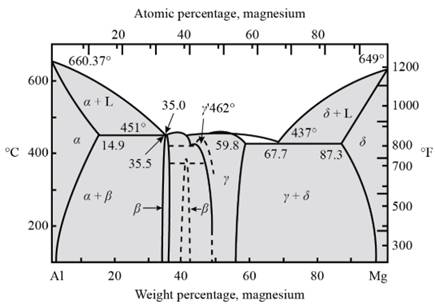

For artificial aging, the temperatures of solvus and eutectic point is determined. For this the curve between the percentage of weight of magnesium and the temperature needs to be drawn.

Fig. 1- Phase diagram of Al-Mg system

Explanation of Solution

Form the above graph, one gets to know all the temperatures for artificial age hardening of Magnesium-Aluminium alloy

| Temperature | Al- Mg | Al- Mg | Al- Mg |

| Treat at | Quenching | Quenching | Quenching |

| Age at | Temperature below | Temperature below | Temperature below |

Table No.

Thus, artificial age hardening depends on temperature of solid solubility and the eutectic point. Precipitation treat hardening is done by the help of quenching process.

(b)

Interpretation:

The amount of beta precipitates in all weight percentage of magnesium needs to be compared.

Concept Introduction:

The mixture of magnesium with other elements is known as magnesium alloy. The other elements include Zinc, Manganese, aluminum and Copper.

Solidification takes place after complete mixing. It gets phase transformation to Liquid phase and there is no diffusion in the solid phase. With a decrease in the temperature of aluminum, the solubility of aluminum in magnesium also decreases.

If temperature is increased above,

Answer to Problem 12.30P

The amount of beta precipitates in Al-

Explanation of Solution

Consider,

Aging temperature -

Tie line is passing through weight percentage of Mg as -

Hence, now one can calculate beta precipitate as −

For Al-

For Al-

And for Al-

From calculations, one can observe that if the weight percentage of magnesium in aluminum alloy increases then the amount of beta precipitate also increases.

(c)

Interpretation:

The requirement which is not satisfied in age hardening needs to be explained.

Concept Introduction:

The mixture of magnesium with other elements is known as magnesium alloy. The other elements include Zinc, Manganese, Aluminum and Copper.

Solidification takes place after complete mixing. It gets phase transformation to Liquid phase and there is no diffusion in the solid phase. With a decrease in the temperature of aluminum, the solubility of aluminum in magnesium also decreases.

If temperature is increased above,

Answer to Problem 12.30P

After the heat treatment, it can be observed that there is a little strengthening remains because the coherent precipitation is not formed.

Explanation of Solution

Age hardening is used to increase the yield strength of malleable metals like as −

- Aluminium

- Magnesium

- Nickel

- Titanium

The hardening depends on the temperature and its solubility in solid phase which results into pure or fine particles with the removal of the impurity phase. For precipitation, sometimes the alloy is kept at the elevated temperature for hours. This process of time delay is known as Aging.

After testing of the alloys with heat treatment, some amount of strengthening is observed. At this stage there is no formation of coherent precipitation. There is only simple dispersion strength as compared to the age hardening.

Want to see more full solutions like this?

Chapter 12 Solutions

Essentials Of Materials Science And Engineering

- Oxygen (molar mass 32 kg/kmol) expands reversibly in a cylinder behind a piston at a constant pressure of 3 bar. The volume initially is 0.01 m3 and finally is 0.03 m3; the initial temperature is 17°C. Calculate the work input and the heat supplied during the expansion. Assume oxygen to be an ideal gas and take cp = 0.917 kJ/kg K. For 1 bonus mark explain why (using your understanding of thermodynamics) that oxygen is used in this context rather than water vapour.arrow_forwardThe excitation of a three-phase synchronous motor connected in parallel with a load of 500 kW operating at 0-85 p.f. lagging is adjusted to improve the overall p.f. of the system to 0.95 lagging. If the mechanical load on the motor is 120 kW, calculate the kVA input to the synchronous motor and its p.f.?arrow_forwardusing r languagearrow_forward

- using r languagearrow_forwardHydrodynamic Lubrication Theory Q1: Convert this equations into Python by 1- ah ap a h³ ap 1..ah = ax 12μ ax ay 12μ ay 2 ax Where P=P(x, y) is the oil film pressure. 2- 3μU (L² ε sin P= C²R (1+ cos 0)³ Q2: prove that |h(0) = C(1+ cos 0) ?arrow_forwardA domestic load of 2300 kW at 0.88 p.f lagging and a motors load of 3400 kW at 0.85 p.f lagging are supplied by two alternators operating in parallel. If one alternator is delivering a load of 3300 kW at 0.9 p.f lagging, what will be the output power and p.f of the other alternator?arrow_forward

- Design a bank of capacitors to provide 60V and 2kWh energy to capture and store regen breaking energy. Use commercial supercapacitor cells at 3V and 3600F. Capacitor voltage drops almost linearly during discharge and below half voltage maximum it doesn’t provide significant power. If we discharge a fully charged capacitor to its half voltage maximum, how much energy can be discharged compared to a full-discharged capacitor (show your calculation)?arrow_forwardYou are given a class that processes purchases for an online store. The class receives calls to: • Retrieve the prices for items from a database • Record the sold items • Update the database • Refresh the webpage a. What architectural pattern is suitable for this scenario? Illustrate your answer by drawing a model for the solution, showing the method calls/events. b. Comment on how applying this pattern will impact the modifiability of the system. c. Draw a sequence diagram for the update operation.arrow_forward8-1) similar to Lathi & Ding, Prob. P.5.1-2 The figure below shows the Fourier spectra of signals of g,(t) and g₁(t). Determine the Nyquist rate and the corresponding sampling interval for signals of g,(t), g,(t), g₁(1) - g¸(1), g¸³(t), and g₁(1)g₁(1). Hint: Use the frequency convolution and the width property of convolution. G₁(f) G₂(f) -8000 0 8000 f -20000 10 20000 farrow_forward

- ### To make a conclusion for a report of an experiment on rockets, in which the openrocket software was used for the construction and modeling of two rockets: one one-stage and one two-stage. First rocket (single-stage) reached a maximum vertical speed of 200 m/s and a maximum height of 1000 m The second rocket (two-stage) reached a maximum vertical speed of 250 m/s and a maximum height of 1800 m To make a simplified conclusion, taking into account the efficiency of the software in the study of rocketsarrow_forwardCalculate the approximate values of the starting current, full-load current, and no- load current of a 150 horsepower, 575 V, 3- phase induction motor.arrow_forwardWhat is the difference between saturated liquid and compressed liquid? What is the difference between the critical point and the triple pointarrow_forward

MATLAB: An Introduction with ApplicationsEngineeringISBN:9781119256830Author:Amos GilatPublisher:John Wiley & Sons Inc

MATLAB: An Introduction with ApplicationsEngineeringISBN:9781119256830Author:Amos GilatPublisher:John Wiley & Sons Inc Essentials Of Materials Science And EngineeringEngineeringISBN:9781337385497Author:WRIGHT, Wendelin J.Publisher:Cengage,

Essentials Of Materials Science And EngineeringEngineeringISBN:9781337385497Author:WRIGHT, Wendelin J.Publisher:Cengage, Industrial Motor ControlEngineeringISBN:9781133691808Author:Stephen HermanPublisher:Cengage Learning

Industrial Motor ControlEngineeringISBN:9781133691808Author:Stephen HermanPublisher:Cengage Learning Basics Of Engineering EconomyEngineeringISBN:9780073376356Author:Leland Blank, Anthony TarquinPublisher:MCGRAW-HILL HIGHER EDUCATION

Basics Of Engineering EconomyEngineeringISBN:9780073376356Author:Leland Blank, Anthony TarquinPublisher:MCGRAW-HILL HIGHER EDUCATION Structural Steel Design (6th Edition)EngineeringISBN:9780134589657Author:Jack C. McCormac, Stephen F. CsernakPublisher:PEARSON

Structural Steel Design (6th Edition)EngineeringISBN:9780134589657Author:Jack C. McCormac, Stephen F. CsernakPublisher:PEARSON Fundamentals of Materials Science and Engineering...EngineeringISBN:9781119175483Author:William D. Callister Jr., David G. RethwischPublisher:WILEY

Fundamentals of Materials Science and Engineering...EngineeringISBN:9781119175483Author:William D. Callister Jr., David G. RethwischPublisher:WILEY