Mechanics of Materials, 7th Edition

7th Edition

ISBN: 9780073398235

Author: Ferdinand P. Beer, E. Russell Johnston Jr., John T. DeWolf, David F. Mazurek

Publisher: McGraw-Hill Education

expand_more

expand_more

format_list_bulleted

Textbook Question

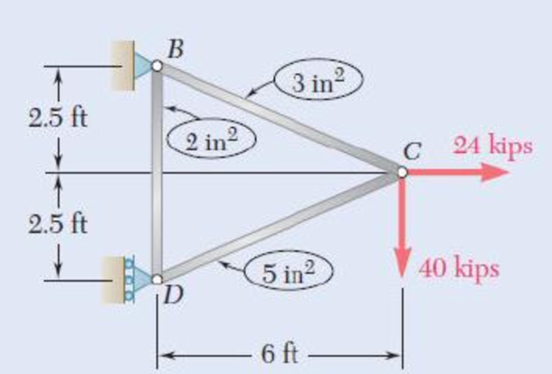

Chapter 11.3, Problem 23P

Each member of the truss shown is made of aluminum and has the cross-sectional area shown. Using E = 10.5 × 106 psi, determine the strain energy of the truss for the loading shown.

Fig. P11.23

Expert Solution & Answer

Want to see the full answer?

Check out a sample textbook solution

Students have asked these similar questions

H.W.7 A rigid steel bar ABC is supported by three rods.

There is no strain in the rods before load P is applied. After

load P is applied, the axial strain in rod (1) is 1,200 µɛ.

(1)

2,000 mm

(a) Determine the axial strain in rods (2).

(b) Determine the axial strain in rods (2) if there is a 0.5 mm

gap in the connections between rods (2) and the rigid

bar before the load is applied.

520 mm

400 mm

1,250 mm

(2)

A steel cable is used to support an elevator cage at the bottom of a 1700-ft-deep mineshaft. A uniform normal strain of 220 μin./in. is

produced in the cable by the weight of the cage. At each point, the weight of the cable produces an additional normal strain that is

proportional to the length of the cable below the point. Assume D = 1700 ft and d= 700 ft. If the total normal strain in the cable at the

cable drum (upper end of the cable) is 520 uin./in., determine

(a) the strain in the cable at a depth of 700 ft.

(b) the total elongation of the cable.

Drum

Cable

Answers:

(a)

ε =

(b) 8 =

y

i

i

Elevator cage

D

X

μin./in.

in.

Prove that the sum of the normal strains in perpendicular directions is constant, i.e., Px + Py = Px′ + Py′

Chapter 11 Solutions

Mechanics of Materials, 7th Edition

Ch. 11.3 - Determine the modulus of resilience for each of...Ch. 11.3 - Determine the modulus of resilience for each of...Ch. 11.3 - Determine the modulus of resilience for each of...Ch. 11.3 - Determine the modulus of resilience for each of...Ch. 11.3 - The stress-strain diagram shown has been drawn...Ch. 11.3 - The stress-strain diagram shown has been drawn...Ch. 11.3 - Prob. 7PCh. 11.3 - Prob. 8PCh. 11.3 - Using E = 29 106 psi, determine (a) the strain...Ch. 11.3 - Using E = 200 GPa, determine (a) the strain energy...

Ch. 11.3 - A 30-in. length of aluminum pipe of...Ch. 11.3 - A single 6-mm-diameter steel pin B is used to...Ch. 11.3 - Prob. 13PCh. 11.3 - Prob. 14PCh. 11.3 - The assembly ABC is made of a steel for which E =...Ch. 11.3 - Show by integration that the strain energy of the...Ch. 11.3 - Prob. 17PCh. 11.3 - Prob. 18PCh. 11.3 - Prob. 19PCh. 11.3 - 11.18 through 11.21 In the truss shown, all...Ch. 11.3 - Prob. 21PCh. 11.3 - Each member of the truss shown is made of aluminum...Ch. 11.3 - Each member of the truss shown is made of aluminum...Ch. 11.3 - 11.24 through 11.27 Taking into account only the...Ch. 11.3 - Prob. 25PCh. 11.3 - 11.24 through 11.27 Taking into account only the...Ch. 11.3 - 11.24 through 11.27 Taking into account only the...Ch. 11.3 - Prob. 28PCh. 11.3 - Prob. 29PCh. 11.3 - Prob. 30PCh. 11.3 - 11.30 and 11.31 Using E = 200 GPa, determine the...Ch. 11.3 - Assuming that the prismatic beam AB has a...Ch. 11.3 - Prob. 33PCh. 11.3 - The design specifications for the steel shaft AB...Ch. 11.3 - Show by integration that the strain energy in the...Ch. 11.3 - The state of stress shown occurs in a machine...Ch. 11.3 - Prob. 37PCh. 11.3 - The state of stress shown occurs in a machine...Ch. 11.3 - Prob. 39PCh. 11.3 - Prob. 40PCh. 11.3 - Prob. 41PCh. 11.5 - A 5-kg collar D moves along the uniform rod AB and...Ch. 11.5 - The 18-lb cylindrical block E has a horizontal...Ch. 11.5 - The cylindrical block E has a speed v0 =16 ft/s...Ch. 11.5 - Prob. 45PCh. 11.5 - Prob. 46PCh. 11.5 - The 48-kg collar G is released from rest in the...Ch. 11.5 - Prob. 48PCh. 11.5 - Prob. 49PCh. 11.5 - Prob. 50PCh. 11.5 - Prob. 51PCh. 11.5 - The 2-kg block D is dropped from the position...Ch. 11.5 - The 10-kg block D is dropped from a height h = 450...Ch. 11.5 - Prob. 54PCh. 11.5 - A 160-lb diver jumps from a height of 20 in. onto...Ch. 11.5 - Prob. 56PCh. 11.5 - A block of weight W is dropped from a height h...Ch. 11.5 - 11.58 and 11.59 Using the method of work and...Ch. 11.5 - 11.58 and 11.59 Using the method of work and...Ch. 11.5 - 11.60 and 11.61 Using the method of work and...Ch. 11.5 - 11.60 and 11.61 Using the method of work and...Ch. 11.5 - 11.62 and 11.63 Using the method of work and...Ch. 11.5 - 11.62 and 11.63 Using the method of work and...Ch. 11.5 - Using the method of work and energy, determine the...Ch. 11.5 - Using the method of work and energy, determine the...Ch. 11.5 - The 20-mm diameter steel rod BC is attached to the...Ch. 11.5 - Torques of the same magnitude T are applied to the...Ch. 11.5 - Prob. 68PCh. 11.5 - The 20-mm-diameter steel rod CD is welded to the...Ch. 11.5 - The thin-walled hollow cylindrical member AB has a...Ch. 11.5 - 11.71 and 11.72 Each member of the truss shown has...Ch. 11.5 - 11.71 and 11.72 Each member of the truss shown has...Ch. 11.5 - Each member of the truss shown is made of steel...Ch. 11.5 - Each member of the truss shown is made of steel....Ch. 11.5 - Each member of the truss shown is made of steel...Ch. 11.5 - The steel rod BC has a 24-mm diameter and the...Ch. 11.9 - 11.77 and 11.78 Using the information in Appendix...Ch. 11.9 - 11.77 and 11.78 Using the information in Appendix...Ch. 11.9 - 11.79 through 11.82 For the beam and loading...Ch. 11.9 - 11.79 through 11.82 For the beam and loading...Ch. 11.9 - 11.79 through 11.82 For the beam and loading...Ch. 11.9 - 11.79 through 11.82 For the beam and loading...Ch. 11.9 - 11.83 through 11.85 For the prismatic beam shown,...Ch. 11.9 - 11.83 through 11.85 For the prismatic beam shown,...Ch. 11.9 - 11.83 through 11.85 For the prismatic beam shown,...Ch. 11.9 - 11.86 through 11.88 For the prismatic beam shown,...Ch. 11.9 - 11.86 through 11.88 For the prismatic beam shown,...Ch. 11.9 - 11.86 through 11.88 For the prismatic beam shown,...Ch. 11.9 - For the prismatic beam shown, determine the slope...Ch. 11.9 - For the prismatic beam shown, determine the slope...Ch. 11.9 - For the beam and loading shown, determine the...Ch. 11.9 - For the beam and loading shown, determine the...Ch. 11.9 - 11.93 and 11.94 For the beam and loading shown,...Ch. 11.9 - 11.93 and 11.94 For the beam and loading shown,...Ch. 11.9 - For the beam and loading shown, determine the...Ch. 11.9 - For the beam and loading shown, determine the...Ch. 11.9 - Prob. 97PCh. 11.9 - For the beam and loading shown, determine the...Ch. 11.9 - 11.99 and 11.100 For the truss and loading shown,...Ch. 11.9 - 11.99 and 11.100 For the truss and loading shown,...Ch. 11.9 - 11.101 and 11.102 Each member of the truss shown...Ch. 11.9 - 11.101 and 11.102 Each member of the truss shown...Ch. 11.9 - 11.103 and 11.104 Each member of the truss shown...Ch. 11.9 - 11.103 and 11 104 Each member of the truss shown...Ch. 11.9 - A uniform rod of flexural rigidity EI is bent and...Ch. 11.9 - For the uniform rod and loading shown and using...Ch. 11.9 - For the beam and loading shown and using...Ch. 11.9 - Two rods AB and BC of the same flexural rigidity...Ch. 11.9 - Three rods, each of the same flexural rigidity EI,...Ch. 11.9 - Three rods, each of the same flexural rigidity EI,...Ch. 11.9 - 11.111 through 11.115 Determine the reaction at...Ch. 11.9 - 11.111 through 11.115 Determine the reaction at...Ch. 11.9 - 11.111 through 11.115 Determine the reaction at...Ch. 11.9 - 11.111 through 11.115 Determine the reaction at...Ch. 11.9 - 11.111 through 11.115 Determine the reaction at...Ch. 11.9 - For the uniform beam and loading shown, determine...Ch. 11.9 - 11.117 through 11.120 Three members of the same...Ch. 11.9 - 11.117 through 11.120 Three members of the same...Ch. 11.9 - 11.117 through 11.120 Three members of the same...Ch. 11.9 - 11.117 through 11.120 Three members of the same...Ch. 11.9 - 11.121 and 11.122 Knowing that the eight members...Ch. 11.9 - 11.121 and 11.122 Knowing that the eight members...Ch. 11 - Rod AB is made of a steel for which the yield...Ch. 11 - Each member of the truss shown is made of steel...Ch. 11 - The ship at A has just started to drill for oil on...Ch. 11 - Collar D is released from rest in the position...Ch. 11 - Each member of the truss shown is made of steel...Ch. 11 - A block of weight W is placed in contact with a...Ch. 11 - Two solid steel shafts are connected by the gears...Ch. 11 - A 160-lb diver jumps from a height of 20 in. onto...Ch. 11 - For the prismatic beam shown, determine the slope...Ch. 11 - A disk of radius a has been welded to end B of the...Ch. 11 - A uniform rod of flexural rigidity EI is bent and...Ch. 11 - The steel bar ABC has a square cross section of...

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- H.W.7 A rigid steel bar ABC is supported by three rods. There is no strain in the rods before load P is applied. After load P is applied, the axial strain in rod (1) is 1,200 µue. (1) 2,000 mm (a) Determine the axial strain in rods (2). (b) Determine the axial strain in rods (2) if there is a 0.5 mm gap in the connections between rods (2) and the rigid bar before the load is applied. 520 mm 400 mm 1,250 mm (2)arrow_forwardA solid 20-mm-diameter shaft is subjected to an axial load P. The shaft is made of aluminum [E = 70 GPa; v=0.33]. A strain gage is mounted on the shaft at the orientation shown in Fig. P13.77. (a) If P= 18.5 kN, determine the strain reading that would be expected from the gage. (b) If the gage indicates a strain value of ε = 950 ue, determine the axial force P applied to the shaft.arrow_forwardA composite rod of overall length of 200 mm comprised of a steel rod and brass rod attached rigidly to the end. The diameter and the length of the steel rod is 10 mm and 120 mm, respectively, the diameter and the length of the brass rod as 20 mm and 80 mm respectively. The rod is used as a tie in a link mechanism and the strain in the brass rod is limited to 0.0053. Given that the total extension of the composite rod must not exceed 0,1624 mm and E for steel is 200 GPa, respectively. Calculate : A) Strain in the steel rod B) Load carried by the steel and the brass rods C) Modulus of elasticity for the brass. Can you please resend that question as it appears to be blank??arrow_forward

- A steel cable is used to support an elevator cage at the bottom of a 2400-ft-deep mineshaft. A uniform normal strain of 300 μin./in. is produced in the cable by the weight of the cage. At each point, the weight of the cable produces an additional normal strain that is proportional to the length of the cable below the point. Assume D = 2400 ft and d = 200 ft. If the total normal strain in the cable at the cable drum (upper end of the cable) is 620 uin./in., determine (a) the strain in the cable at a depth of 200 ft. (b) the total elongation of the cable. Drum Answers: (a) Cable + ε = i Elevator cage D X uin./in.arrow_forwardQuestion-2: A solid 20-mm-diameter shaft is subjected to an axial load P. The shaft is made of aluminum [E = 70 GPa; v= 0.33]. A strain gage is mounted on the shaft at the orientation shown in Fig. P13.77. (a) If P = 18.5 kN, determine the strain reading that would be expected from the gage. (b) If the gage indicates a strain value of e= 950 uE, determine the axial force P applied to the shaft.arrow_forwardA steel wire 30 ft long, hanging vertically, supports a load of 500 lb. Neglecting the weight of the wire, determine the required diameter if the stress is not to exceed 20 ksi and the total elongation is not to exceed 0.10 in. Assume E = 29 × 10° psi. 0.22 in 0.30 in 0.28 in. 0.20 in.arrow_forward

- A composite rod of overall length of 200 mm comprised of a steel rod and brass rod attached rigidly to the end. The diameter and the length of the steel rod are given as 10 mm and 120 mm,respectively, the diameter and the length of the brass rod as 20 mm and 80 mm respectively. The rod is used as a tie in a link mechanism and the strain in the brass rod is limited to 0,00053. Given that the total extension of the composite rod must not exceed 0,1624 mm and E for steel is 200 GPa, respectively. Determine : A) Strain in the steel rod B) Load carried by the steel and brass rods C) Modulus of elasticity for the brassarrow_forwardThe bar ABC shown is loaded by a force P1=20 kN and P2= 40 kN at points C and B respectively. The bar has a constant axial rigidity of 120 x 10^6 N. A. Determine the strain energy of the bar when the force P1 acts alone (P2=0)B. Determine the strain energy of the bar when the force P2 acts alone (P1=0)C. Determine the strain energy when the forces P1 and P2 are acting simultaneously upon the bar.arrow_forwardAfter load P is applied to the pin-connected structure, a normal strain of = +650 µe is measured in the longitudinal direction of member (1). The cross-sectional area of member (1) is A₁ = 0.6 in.2, its elastic modulus is E₁ = 31000 ksi, and its yield strength is 33 ksi. Assume a=6.25 ft, b=7.75 ft, c=4.5 ft, and d=3.75 ft. (a) Determine the axial force in member (1), the applied load P, and the resultant force at pin B. (b) The ultimate shear strength of the steel pins is 52 ksi. Determine the minimum diameter for the pin at B if a factor of safety of 2.2 with respect to the ultimate shear strength is required. (c) Compute the factor of safety for member (1) with respect to its yield strength. (1) a D Answer: 0₁ = 1.6377 B (a) Determine the axial stress o, in member (1). ksi. barrow_forward

- The normal strain in a suspended bar of material of varying cross section due to its own weight is given by the expression γy/3E where γ = 2.9 lb/in.3 is the specific weight of the material, y = 3.4 in. is the distance from the free (i.e., bottom) end of the bar, L = 17 in. is the length of the bar, and E = 24000 ksi is a material constant. Determine, (a) the change in length of the bar due to its own weight. (b) the average normal strain over the length L of the bar. (c) the maximum normal strain in the bar.arrow_forward1. Neglecting the weight of the steel wire, determine its required diameter if it is 30 ft long, hanging vertically and supports a 500 lb load. Also, its stress is not to exceed 20 000 psi and the total elongation is not to exceed 0.40 in. Assume E = 49x 10° psi. 30 ft 500 lbarrow_forwardTwo tempered-steel bars, each 316316 in. thick, are bonded to a 1212 -in. mild-steel bar. This composite bar is subjected as shown to a centric axial load of magnitude P. Both steels are elastoplastic with E = 29 × 106 psi and with yield strengths equal to 100 ksi and 50 ksi, respectively, for the tempered and mild steel. Determine the residual stresses in the tempered-steel bars if the load P is gradually increased from zero to 103 kips and then decreased back to zero. The residual stress in the tempered steel bars isarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY

An Introduction to Stress and Strain; Author: The Efficient Engineer;https://www.youtube.com/watch?v=aQf6Q8t1FQE;License: Standard YouTube License, CC-BY