Concept explainers

Santa Rosa Industries uses a standard-costing system to assist in the evaluation of operations. The company has had considerable trouble in recent months with suppliers and employees, so much so that management hired a new production supervisor, Frank Schmidt. The new supervisor has been on the job for five months and has seemingly brought order to an otherwise chaotic situation.

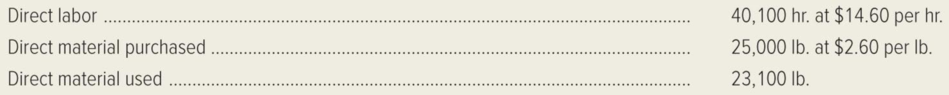

The vice president of manufacturing recently commented that “… Schmidt has really done the trick. The change to a new direct-material supplier and Schmidt’s team-building/morale-boosting training exercises have truly brought things under control.” The VP’s comments were based on both a plant tour, where he observed a contented workforce, and a review of the following data, which was excerpted from a performance report:

These variances are especially outstanding, given that the amounts are favorable and small. (Santa Rosa’s budgeted material and labor costs generally each average about $350,000 for similar periods.) Additional data follow.

- The company purchased and consumed 45,000 pounds of direct materials at $7.70 per pound, and paid $16.25 per hour for 20,900 direct-labor hours of activity. Total completed production amounted to 9,500 units.

- A review of the firm’s standard cost records found that each completed unit requires 4.2 pounds of direct material at $8.80 per pound and 2.6 direct-labor hours at $14 per hour.

Required:

- 1. On the basis of the information contained in the performance report, should Santa Rosa be concerned about its variances? Why?

- 2. Calculate the company’s direct-material variances and direct-labor variances.

- 3. On the basis of your answers to requirement (2), should Santa Rosa be concerned about its variances? Why?

- 4. Are things going as smoothly as the vice president believes? Evaluate the company’s variances and determine whether the change to a new supplier and Schmidt’s team-building/morale-boosting training exercises appear to be working. Explain.

- 5. Is it possible that some of the company’s current problems lie outside Schmidt’s area of responsibility? Explain.

Want to see the full answer?

Check out a sample textbook solution

Chapter 10 Solutions

Connect 1-Semester Access Card for Managerial Accounting: Creating Value in a Dynamic Business Environment (NEW!!)

- Terri Ronsin had recently been transferred to the Home Security Systems Division of National Home Products. Shortly after taking over her new position as divisional controller, she was asked to develop the division’s predetermined overhead rate for the upcoming year. The accuracy of the rate is important because it is used throughout the year and any overapplied or underapplied overhead is closed out to Cost of Goods Sold at the end of the year. National Home Products uses direct labor-hours in all of its divisions as the allocation base for manufacturing overhead. To compute the predetermined overhead rate, Terri divided her estimate of the total manufacturing overhead for the coming year by the production manager’s estimate of the total direct labor-hours for the coming year. She took her computations to the division’s general manager for approval but was quite surprised when he suggested a modification in the base. Her conversation with the general manager of the Home Security…arrow_forwardTerri Ronsin had recently been transferred to the Home Security Systems Division of National Home Products. Shortly after taking over her new position as divisional controller, she was asked to develop the division’s predetermined overhead rate for the upcoming year. The accuracy of the rate is important because it is used throughout the year and any underapplied or overapplied overhead is closed out to Cost of Goods Sold at the end of the year. National Home Products uses direct labor-hours in all of its divisions as the allocation base for manufacturing overhead. To compute the predetermined overhead rate, Terri divided her estimate of the total manufacturing overhead for the coming year by the production manager’s estimate of the total direct labor-hours for the coming year. She took her computations to the division’s general manager for approval but was quite surprised when he suggested a modification in the allocation base. Her conversation with the general manager of the Home…arrow_forwardAs an assistant cost accountant for Mississippi Industries, you have been assigned to review the activity base for the predetermined factory overhead rate. The president, Tony Favre, has expressed concern that the over- or underapplied overhead has fluctuated excessively over the years.An analysis of the company’s operations and use of the current overhead rate (direct labor cost) has narrowed the possible alternative overhead bases to direct labor cost and machine hours. For the past five years, the following data have been gathered: Attachment In teams:1. Calculate a predetermined factory overhead rate for each alternative base, assuming that rates would have been determined by relating the total amount of factory overhead for the past five years to the base.2. For each of the past five years, determine the over- or underapplied overhead based on the two predetermined overhead rates developed in part (1).3. Which predetermined overhead rate would you recommend? Discuss the basis for…arrow_forward

- Muscat Tubes Manufacturing LLC is a manufacturer of television picture tubes. The company must keep various types of materials on hand for the manufacturing process. The store manager is having difficulty keeping track of all the inventory. When compared to last year, the amount of material lost has increased, which is a source of concern for the store manager. He wishes to employ an effective tool for controlling material loss. While exploring, he came across the concept of ABC analysis, which is used by many MNCs around the world. Because he has no background in costing, he is unable to grasp the concept. He asked you to explain the following because you are the company's cost accounting executive: Working/Application of ABC analysis?arrow_forwardTerri Ronsin had recently been transferred to the House Security Division of National Home products. Shortly after taking over her new position as individual controller, she was asked to develop the divisions' predetermined overhead rate for the upcoming year. The accuracy of the rate is important because it is used throughout the year and any over applied or under applied overhead is closed out to Cost of Goods Sold at the end of the year. National Home Products uses direct labor -hours in all of its divisions as the allocation base for manufacturing overhead. To compute the pretermined overhead rate, Terri divided her estimate of the total manufacturing overhead for the coming year by the production manager's estimate of the total direct labor hours for the coming year. She took her computations to the division's general manager for approval but was quite surprised when he suggested a modification in the base. Her conversation with the general manager…arrow_forwardEmery Manufacturing Company produces component parts for the farm equipment industry and has recently undergone a major computer system conversion. Jake Murray, the controller, has established a troubleshooting team to alleviate accounting problems that have occurred since the conversion. Jake has chosen Gus Swanson, assistant controller, to head the team that will include Linda Wheeler, cost accountant; Cindy Madsen, financial analyst; Randy Lewis, general accounting supervisor; and Max Crandall, financial accountant. The team has been meeting weekly for the last month. Gus insists on being part of all the team conversations in order to gather information, to make the final decision on any ideas or actions that the team develops, and to prepare a weekly report for Jake. He has also used this team as a forum to discuss issues and disputes about him and other members of Emerys top management team. At last weeks meeting, Gus told the team that he thought a competitor might purchase the common stock of Emery, because he had overheard Jake talking about this on the telephone. As a result, most of Emerys employees now informally discuss the sale of Emerys common stock and how it will affect their jobs. Required: Is Gus Swansons discussion with the team about the prospective sale of Emery unethical? Discuss, citing specific standards from the code of ethical conduct to support your position. (CMA adapted)arrow_forward

- Tonya Martin, CMA and controller or the Parts Division of Gunderson Inc., was meeting with Doug Adams, manager of the division. The topic of discussion was the assignment of overhead costs to jobs and their impact on the divisions pricing decisions. Their conversation was as follows: Tonya: Doug, as you know, about 25% of our business is based on government contracts, with the other 75% based on jobs from private sources won through bidding. During the last several years, our private business has declined. We have been losing more bids than usual. After some careful investigation, I have concluded that we are overpricing some jobs because of improper assignment of overhead costs. Some jobs are also being underpriced. Unfortunately, the jobs being overpriced are coming from our higher-volume, labor-intensive products, so we are losing business. Dong: I think I understand. Jobs associated with our high-volume products are being assigned more overhead than they should be receiving. Then when we add our standard 40% markup, we end up with a higher price than our competitors, who assign costs more accurately. Tonya: Exactly. We have two producing departments, one labor-intensive and the other machine-intensive. The labor-intensive department generates much less overhead than the machine-intensive department. Furthermore, virtually all of our high-volume jobs are labor-intensive. We have been using a plantwide rate based on direct labor hours to assign overhead to all jobs. As a result, the high-volume, labor-intensive jobs receive a greater share of the machine-intensive departments overhead than they deserve. This problem can be greatly alleviated by switching to departmental overhead rates. For example, an average high-volume job would be assigned 100,000 of overhead using a plantwide rate and only 70,000 using departmental rates. The change would lower our bidding price on high-volume jobs by an average of 42,000 per job. By increasing the accuracy of our product costing, we can make better pricing decisions and win back much of our private-sector business. Doug: Sounds good. When can you implement the change in overhead rates? Tonya: It wont take long. I can have the new system working within four to six weekscertainly by the start of the new fiscal year. Doug: Hold it. I just thought of a possible complication. As I recall, most of our government contract work is done in the labor-intensive department. This new overhead assignment scheme will push down the cost on the government jobs, and we will lose revenues. They pay us full cost plus our standard markup. This business is not threatened by our current costing procedures, but we cant switch our rates for only the private business. Government auditors would question the lack of consistency in our costing procedures. Tonya: You do have a point. I thought of this issue also. According to my estimates, we will gain more revenues from the private sector than we will lose from our government contracts. Besides, the costs of our government jobs are distorted. In effect, we are overcharging the government. Doug: They dont know that and never would unless we switch our overhead assignment procedures. I think I have the solution. Officially, lets keep our plantwide overhead rate. All of the official records will reflect this overhead costing approach for both our private and government business. Unofficially. I want you to develop a separate set of books that can be used to generate the information we need to prepare competitive bids for our private-sector business. Required: 1. Do you believe that the solution proposed by Doug is ethical? Explain. 2. Suppose that Tonya decides that Dougs solution is not right and objects strongly. Further suppose that, despite Tonyas objections, Doug insists strongly on implementing the action. What should Tonya do?arrow_forwardRecently, Ulrich Company received a report from an external consulting group on its quality costs. The consultants reported that the companys quality costs total about 21 percent of its sales revenues. Somewhat shocked by the magnitude of the costs, Rob Rustin, president of Ulrich Company, decided to launch a major quality improvement program. For the coming year, management decided to reduce quality costs to 17 percent of sales revenues. Although the amount of reduction was ambitious, most company officials believed that the goal could be realized. To improve the monitoring of the quality improvement program, Rob directed Pamela Golding, the controller, to prepare monthly performance reports comparing budgeted and actual quality costs. Budgeted costs and sales for the first two months of the year are as follows: The following actual sales and actual quality costs were reported for January: Required: 1. Reorganize the monthly budgets so that quality costs are grouped in one of four categories: appraisal, prevention, internal failure, or external failure. (Essentially, prepare a budgeted cost of quality report.) Also, identify each cost as variable (V) or fixed (F). (Assume that no costs are mixed.) 2. Prepare a performance report for January that compares actual costs with budgeted costs. Comment on the companys progress in improving quality and reducing its quality costs.arrow_forwardIn 2011, Milton Thayne, president of Carbondale Electronics, received a report indicating that quality costs were 31 percent of sales. Faced with increasing pressures from imported goods, Milton resolved to take measures to improve the overall quality of the companys products. After hiring a consultant in 20x0, the company began an aggressive program of total quality control. At the end of 20x5, Milton requested an analysis of the progress the company had made in reducing and controlling quality costs. The Accounting Department assembled the following data: Required: 1. Compute the quality costs as a percentage of sales by category and in total for each year. 2. Prepare a multiple-year trend graph for quality costs, both by total costs and by category. Using the graph, assess the progress made in reducing and controlling quality costs. Does the graph provide evidence that quality has improved? Explain. 3. Using the 20x1 quality cost relationships (assume all costs are variable), calculate the quality costs that would have prevailed in 20x4. By how much did profits increase in 20x4 because of the quality improvement program? Repeat for 20x5.arrow_forward

- Big Mikes, a large hardware store, has gathered data on its overhead activities and associated costs for the past 10 months. Nizam Sanjay, a member of the controllers department, believes that overhead activities and costs should be classified into groups that have the same driver. He has decided that unloading incoming goods, counting goods, and inspecting goods can be grouped together as a more general receiving activity, since these three activities are all driven by the number of receiving orders. The 10 months of data shown below have been gathered for the receiving activity. Required: 1. Prepare a scattergraph, plotting the receiving costs against the number of purchase orders. Use the vertical axis for costs and the horizontal axis for orders. 2. Select two points that make the best fit, and compute a cost formula for receiving costs. 3. Using the high-low method, prepare a cost formula for the receiving activity. 4. Using the method of least squares, prepare a cost formula for the receiving activity. What is the coefficient of determination?arrow_forwardIn 20X1, Don Blackburn, president of Price Electronics, received a report indicating that quality costs were 31% of sales. Faced with increasing pressures from imported goods. Don resolved to take measures to improve the overall quality of the companys products. After hiring a consultant in 20X1, the company began an aggressive program of total quality control. At the end of 20X5, Don requested an analysis of the progress the company had made in reducing and controlling quality costs. The accounting department assembled the following data: Required: 1. Compute the quality costs as a percentage of sales by category and in total for each year. 2. Prepare a multiple-year trend graph for quality costs, both by total costs and by category. Using the graph, assess the progress made in reducing and controlling quality costs. Does the graph provide evidence that quality has improved? Explain. 3. Using the 20X1 quality cost relationships (assume all costs are variable), calculate the quality costs that would have prevailed in 20X4. By how much did profits increase in 20X4 because of the quality improvement program? Repeat for 20X5.arrow_forwardAt the beginning of the last quarter of 20x1, Youngston, Inc., a consumer products firm, hired Maria Carrillo to take over one of its divisions. The division manufactured small home appliances and was struggling to survive in a very competitive market. Maria immediately requested a projected income statement for 20x1. In response, the controller provided the following statement: After some investigation, Maria soon realized that the products being produced had a serious problem with quality. She once again requested a special study by the controllers office to supply a report on the level of quality costs. By the middle of November, Maria received the following report from the controller: Maria was surprised at the level of quality costs. They represented 30 percent of sales, which was certainly excessive. She knew that the division had to produce high-quality products to survive. The number of defective units produced needed to be reduced dramatically. Thus, Maria decided to pursue a quality-driven turnaround strategy. Revenue growth and cost reduction could both be achieved if quality could be improved. By growing revenues and decreasing costs, profitability could be increased. After meeting with the managers of production, marketing, purchasing, and human resources, Maria made the following decisions, effective immediately (end of November 20x1): a. More will be invested in employee training. Workers will be trained to detect quality problems and empowered to make improvements. Workers will be allowed a bonus of 10 percent of any cost savings produced by their suggested improvements. b. Two design engineers will be hired immediately, with expectations of hiring one or two more within a year. These engineers will be in charge of redesigning processes and products with the objective of improving quality. They will also be given the responsibility of working with selected suppliers to help improve the quality of their products and processes. Design engineers were considered a strategic necessity. c. Implement a new process: evaluation and selection of suppliers. This new process has the objective of selecting a group of suppliers that are willing and capable of providing nondefective components. d. Effective immediately, the division will begin inspecting purchased components. According to production, many of the quality problems are caused by defective components purchased from outside suppliers. Incoming inspection is viewed as a transitional activity. Once the division has developed a group of suppliers capable of delivering nondefective components, this activity will be eliminated. e. Within three years, the goal is to produce products with a defect rate less than 0.10 percent. By reducing the defect rate to this level, marketing is confident that market share will increase by at least 50 percent (as a consequence of increased customer satisfaction). Products with better quality will help establish an improved product image and reputation, allowing the division to capture new customers and increase market share. f. Accounting will be given the charge to install a quality information reporting system. Daily reports on operational quality data (e.g., percentage of defective units), weekly updates of trend graphs (posted throughout the division), and quarterly cost reports are the types of information required. g. To help direct the improvements in quality activities, kaizen costing is to be implemented. For example, for the year 20x1, a kaizen standard of 6 percent of the selling price per unit was set for rework costs, a 25 percent reduction from the current actual cost. To ensure that the quality improvements were directed and translated into concrete financial outcomes, Maria also began to implement a Balanced Scorecard for the division. By the end of 20x2, progress was being made. Sales had increased to 26,000,000, and the kaizen improvements were meeting or beating expectations. For example, rework costs had dropped to 1,500,000. At the end of 20x3, two years after the turnaround quality strategy was implemented, Maria received the following quality cost report: Maria also received an income statement for 20x3: Maria was pleased with the outcomes. Revenues had grown, and costs had been reduced by at least as much as she had projected for the two-year period. Growth next year should be even greater as she was beginning to observe a favorable effect from the higher-quality products. Also, further quality cost reductions should materialize as incoming inspections were showing much higher-quality purchased components. Required: 1. Identify the strategic objectives, classified by the Balanced Scorecard perspective. Next, suggest measures for each objective. 2. Using the results from Requirement 1, describe Marias strategy using a series of if-then statements. Next, prepare a strategy map. 3. Explain how you would evaluate the success of the quality-driven turnaround strategy. What additional information would you like to have for this evaluation? 4. Explain why Maria felt that the Balanced Scorecard would increase the likelihood that the turnaround strategy would actually produce good financial outcomes. 5. Advise Maria on how to encourage her employees to align their actions and behavior with the turnaround strategy.arrow_forward

Managerial AccountingAccountingISBN:9781337912020Author:Carl Warren, Ph.d. Cma William B. TaylerPublisher:South-Western College Pub

Managerial AccountingAccountingISBN:9781337912020Author:Carl Warren, Ph.d. Cma William B. TaylerPublisher:South-Western College Pub Managerial Accounting: The Cornerstone of Busines...AccountingISBN:9781337115773Author:Maryanne M. Mowen, Don R. Hansen, Dan L. HeitgerPublisher:Cengage Learning

Managerial Accounting: The Cornerstone of Busines...AccountingISBN:9781337115773Author:Maryanne M. Mowen, Don R. Hansen, Dan L. HeitgerPublisher:Cengage Learning Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning Financial And Managerial AccountingAccountingISBN:9781337902663Author:WARREN, Carl S.Publisher:Cengage Learning,

Financial And Managerial AccountingAccountingISBN:9781337902663Author:WARREN, Carl S.Publisher:Cengage Learning,