Cain Components manufactures and distributes various plumbing products used in homes and other buildings. Over time, the production staff has noticed that products they considered easy to make were difficult to sell at margins considered reasonable, while products that seemed to take a lot of staff time were selling well despite recent price increases. A summer intern has suggested that the cost system might be providing misleading information.

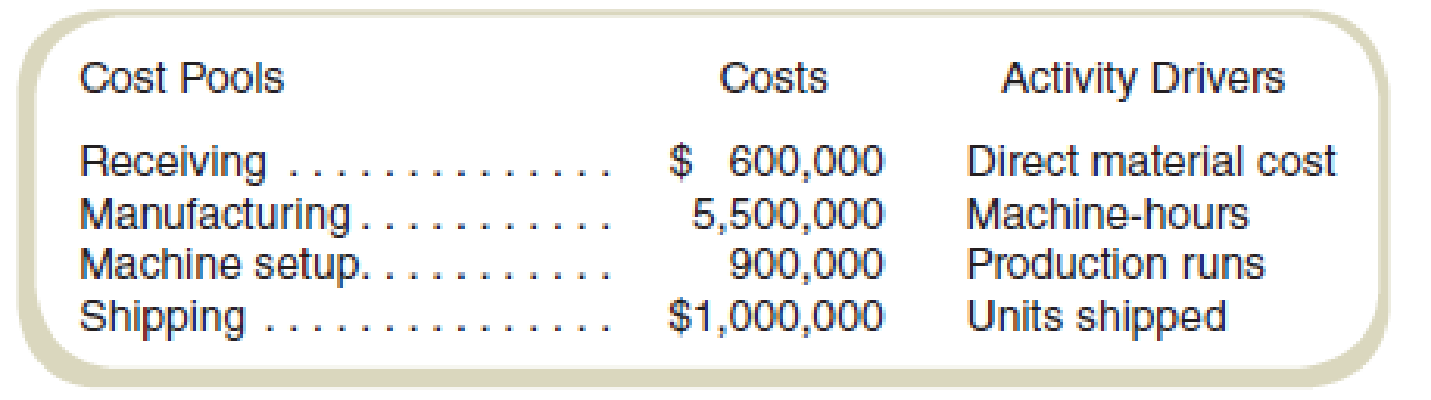

The controller decided that a good summer project for the intern would be to develop, in one self-contained area of the plant, an alternative cost system with which to compare the current system. The intern identified the following cost pools and, after discussion with some plant personnel, appropriate cost drivers for each pool. There were:

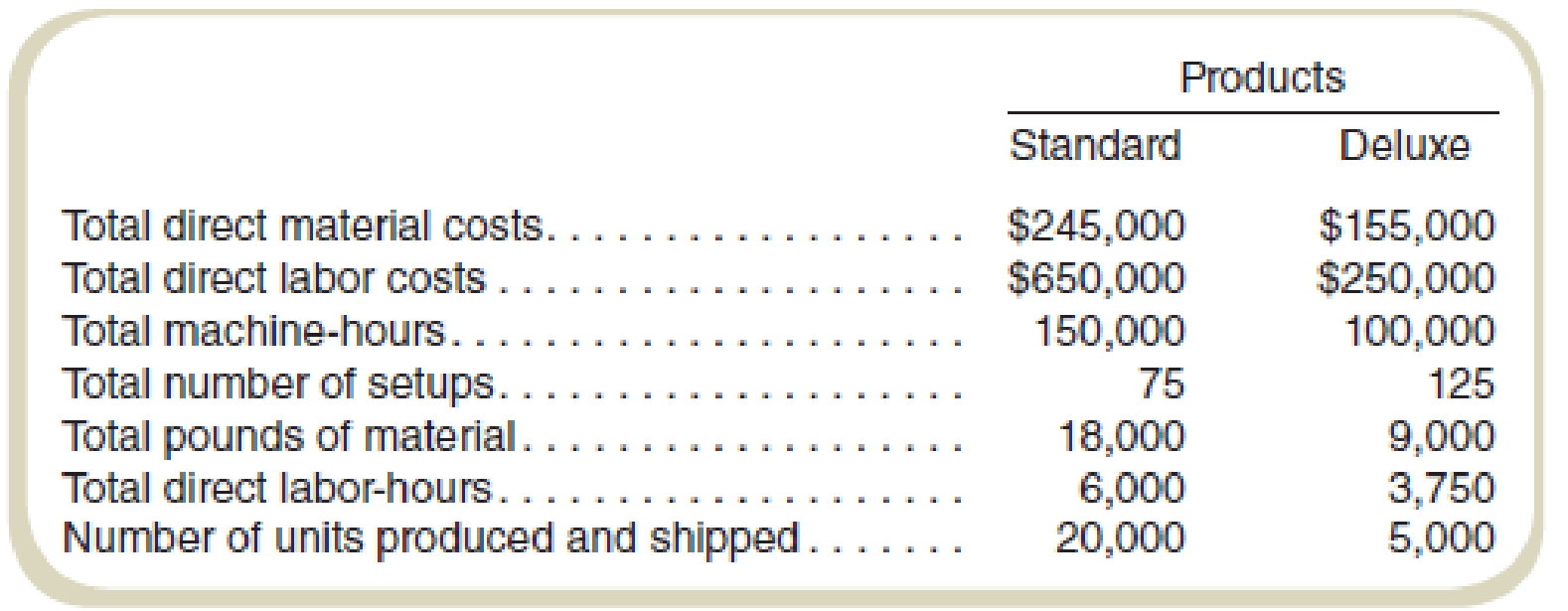

In this particular area, Cain produces two of its many products: Standard and Deluxe. The following are data for production for the latest full year of operations:

Required

- a. The current cost accounting system charges

overhead to products based on machine-hours. What unit product costs will be reported for the two products if the current cost system continues to be used? - b. The intern suggests an ABC system using the cost drivers identified above. What unit product costs will be reported for the two products if the ABC system is used?

- c. Would you recommend that Cain Components adopt the intern’s ABC system? Explain.

Want to see the full answer?

Check out a sample textbook solution

Chapter 9 Solutions

COST ACCOUNTING W/CONNECT

- Discuss the accounting treatment for investments in debt and equity securities.arrow_forwardSaved Required information [The following information applies to the questions displayed below.] On December 1, Jasmin Ernst organized Ernst Consulting. On December 3, the owner contributed $84,310 in assets to launch the business. On December 31, the company's records show the following items and amounts. $ 10,200 Cash withdrawals by owner Cash Accounts receivable 15,200 Consulting revenue Office supplies 3,550 Rent expense Land 45,990 Office equipment 18,310 Accounts payable 8,740 Salaries expense Telephone expense Miscellaneous expenses Owner investments 84,310 $ 2,340 15,200 3,910 7,350 790 610 Use the above information to prepare a December 31 balance sheet for Ernst Consulting. AC Graw Hill ERNST CONSULTING Balance Sheet December 31 $ 0 G-SYNC $ 0 S 0 Barrow_forwardAudit, Fraud, Or Forensic Accounting Introduce yourself to your peers by sharing something unique about your background. Explain how you expect this course will help you move forward in your current or future career. This course covers forensic accounting, so it's important to establish the differences between an audit, a fraud examination, and a forensic accounting engagement. Think about the fraud conviction of Elizabeth Holmes, as described in the video, "Elizabeth Holmes Found Guilty in Theranos Fraud Trial." Then respond to the following: Imagine you are assigned to the Theranos case. Write the first five questions you would ask if you were an auditor, the first five questions as a fraud examiner, and the first five as a forensic accountant. After your questions, explain why the questions and approaches are different among the three roles. Be sure to respond to at least one of your classmates' posts.arrow_forward

- Degregorio Corporation makes a product that uses a material with the following direct material standards: Standard quantity 2.7 kilos per unit Standard price $9 per kilo The company produced 5,700 units in November using 15,760 kilos of the material. During the month, the company purchased 17,830 kilos of direct material at a total cost of $156,904. The direct materials purchases variance is computed when the materials are purchased. The materials quantity variance for November is: a. $3,330 F b. $3,236 F c. $3,330 U d. $3,236 Uarrow_forwardNonearrow_forwardGeneral Accountarrow_forward

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning