a)

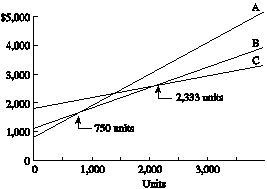

To determine: The graph illustrating the three total cost lines on the same chart.

a)

Answer to Problem 6P

Graph illustrating the three cost lines:

Explanation of Solution

Given information:

Refurbishing cost = $800

Cost of making modifications = $1,100

Purchase of new equipment = $1,800

Refurbishing labor and material costs = $1.10 / board

Modifications labor and material costs = $0.70 / board

New equipment variable costs = $0.40 / board

Formation of cost lines denoted in the graph:

The cost line is formed by multiplying the labor cost and number of units and summing the value with the

Refurbishing cost line (A):

The cost line (A) mentioned in the graph is derived as follows:

Modifications cost line (B):

The cost line (B) mentioned in the graph is derived as follows:

New equipment cost line (C):

The cost line (C) mentioned in the graph is derived as follows:

Calculation of cost at 0 units and arbitrary units of 4,000 using the cost lines (A), (B) and (C):

Refurbishing:

At 0 units:

At 4,000 units:

Modification:

At 0 units:

At 4,000 units:

New equipment:

At 0 units:

At 4,000 units:

The cost values at 0 and 400 units are plotted on the graph.

b)

To determine: The alternative to choose when SB company thinks it can sell more than 3,000 boards.

b)

Answer to Problem 6P

The best alternative when more than 3,000 boards can be sold is alternative 1.

Explanation of Solution

Given information:

Refurbishing cost = $800

Cost of making modifications = $1,100

Purchase of new equipment = $1,800

Refurbishing labor and material costs = $1.10 / board

Modifications labor and material costs = $0.70 / board

New equipment variable costs = $0.40 / board

Formation of cost lines:

The cost line is formed by multiplying the labor cost and number of units and summing the value with the process cost. Let ‘Y’ denote the cost line. Let ‘x’ denote the number of units.

Refurbishing cost line:

Modifications cost line:

New equipment cost line:

Calculation of cost at 3,000 boards:

Alternative 1:

Alternative 1 is refurbishing cost calculated by using equation (A)

Alternative 2:

Alternative 2 is modifications cost calculated by using equation (B)

Alternative 3:

Alternative 3 is new equipment cost calculated by using equation (C)

The total cost of alternative 1 is less than alternative 2 and 3 (3000 < 4100, 3200).

Hence, the best alternative for making 3,000 boards is alternative 3.

c)

To determine: The alternative to choose when SB company thinks that the market for boards will be between 1,000 and 2,000 boards.

c)

Answer to Problem 6P

The best alternative when the market for boards will be between 1,000 and 2,000 boards is making modifications.

Explanation of Solution

Given information:

Refurbishing cost = $800

Cost of making modifications = $1,100

Purchase of new equipment = $1,800

Refurbishing labor and material costs = $1.10 / board

Modifications labor and material costs = $0.70 / board

New equipment variable costs = $0.40 / board

Formation of cost lines:

The cost line is formed by multiplying the labor cost and number of units and summing the value with the process cost. Let ‘Y’ denote the cost line. Let ‘x’ denote the number of units.

Refurbishing cost line:

Modifications cost line:

New equipment cost line:

Calculation of best alternative:

The best alternative is calculated by equating (A) with (B) and (B) with (C).

Calculation of lower limit value:

Lower limit value is calculated by Equating (A) with (B):

Calculation of Upper limit value:

Upper limit value is calculated by Equating (B) with (C):

The boards must be in the range of 1,000 to 2,000. Hence, the best alternative is making major modifications.

Want to see more full solutions like this?

Chapter 7 Solutions

EBK PRINCIPLES OF OPERATIONS MANAGEMENT

- PepsiCo South Africa says the incident where a woman discovered part of a rodent in her loaf of bread, is anisolated occurrence.Durban woman, Nombulelo Mkumla, took to social media last week to share how she discovered the rodent.In a lengthy Facebook post, she said she purchased the loaf of bread from a local shop after work on August 27.For the next days, Mkumla proceeded to use slices of bread from the load to make toast."Then, on the morning of August 31, I took the bread out of the fridge to make toast and noticed something disgusting andscary. I took a picture and sent it to my friends, and one of them said, 'Yi mpuku leyo tshomi' [That's a rat friend]“."I was in denial and suggested it might be something else, but the rat scenario made sense - it's possible the rat got into thebread at the factory, and no one noticed," Mkumla said.She went back to the shop she'd bought the bread from and was told to lay a complaint directly with the supplier.She sent an email with a video and…arrow_forwardThe deaths are included in the discharges; this includes deaths occurring in less than 48 hours and postoperative deaths. Rehabilitation had 362 discharges, 22 deaths, 1<48 hours, 0 Postoperative. what is the gross death rate for the rehabilitation service?arrow_forwardA copy machine is available 24 hours a day. On a typical day, the machine produces 100 jobs. Each job takes about 3 minutes on the machine, 2 minutes of which is processing time and 1 minute is setup time (logging in, defining the job). About 20 percent of the jobs need to be reworked, in which case the setup time and the processing time have to be repeated. The remainder of the time, the equipment is idle. What is the OEE of the equipment?arrow_forward

- How do you think we can keep updating Toyota's ideas as new technologies come out and what customers want keeps changing?arrow_forwardGiven how TPS has helped change things in so many fields, do you think there are parts of it that might be hard to use in areas that aren’t about making things, like in healthcare or services? If so, why do you think that might be?arrow_forwardDo you feel there is anything positive about rework?arrow_forward

- Do you think technology can achieve faster setup times? How would it be implemented in the hospital workforce?arrow_forwardIn your experience or opinion, do you think process changes like organizing workspaces make a bigger difference, or is investing in technology usually the better solution for faster setups?arrow_forwardHave you seen rework done in your business, and what was done to prevent that from occurring again?arrow_forward

- Research a company different than case studies examined and search the internet and find an example of a business that had to rework a process. How was the organization affected to rework a process in order to restore a good flow unit? Did rework hurt a process or improve the organization's operational efficiency? • Note: Include a reference with supportive citations in the discussion reply in your post.arrow_forwardSetup time is very important in affecting a process and the capacity of a process. How do you reduce setup time? Give examples of reducing setup time. Please Provide a referenecearrow_forwardDo you think TPS was successful? If so, how? Are there other companies that have used TPS? If so, give examples. Please provide a referencearrow_forward

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,MarketingMarketingISBN:9780357033791Author:Pride, William MPublisher:South Western Educational Publishing

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,MarketingMarketingISBN:9780357033791Author:Pride, William MPublisher:South Western Educational Publishing Management, Loose-Leaf VersionManagementISBN:9781305969308Author:Richard L. DaftPublisher:South-Western College Pub

Management, Loose-Leaf VersionManagementISBN:9781305969308Author:Richard L. DaftPublisher:South-Western College Pub Contemporary MarketingMarketingISBN:9780357033777Author:Louis E. Boone, David L. KurtzPublisher:Cengage Learning

Contemporary MarketingMarketingISBN:9780357033777Author:Louis E. Boone, David L. KurtzPublisher:Cengage Learning