OPERATIONS MANAGEMENT >C<

14th Edition

ISBN: 9781307701432

Author: Stevenson

Publisher: MCG/CREATE

expand_more

expand_more

format_list_bulleted

Concept explainers

Textbook Question

Chapter 16, Problem 13P

The following

Expert Solution & Answer

Want to see the full answer?

Check out a sample textbook solution

Students have asked these similar questions

working as a program operations manager

12

X1, X230

1 x =0x2

write the Following linear Programming model by

1- general Form

Canonical Forms

Canonical formY

2- Standard Form

Max Z=35X+ 4 X 2 +6 X3

ST. X+2X2-5x3 = 40

3X, + 6X2 + 7x 3 = 30

7x, +lox2 x3 = 50

X3 X 2 X 3 <0

a/ a

Minimum cost

assign each worker for one job at

Jobs

J1

12

33

WI

2

4

6

W2

5

W3

5

33

6

7

Chapter 16 Solutions

OPERATIONS MANAGEMENT >C<

Ch. 16 - Why is scheduling fairly simple for repetitive...Ch. 16 - Prob. 2DRQCh. 16 - What are Gantt charts? How are they used in...Ch. 16 - Prob. 4DRQCh. 16 - Briefly describe each of these priority rules: a....Ch. 16 - Why are priority rules needed?Ch. 16 - What problems not generally found in manufacturing...Ch. 16 - Explain forward and backward schedulings and each...Ch. 16 - Prob. 9DRQCh. 16 - Prob. 10DRQ

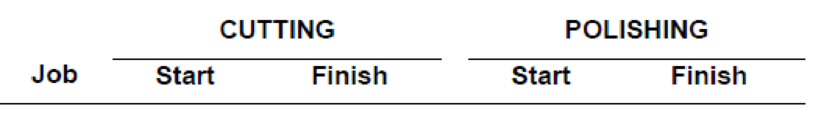

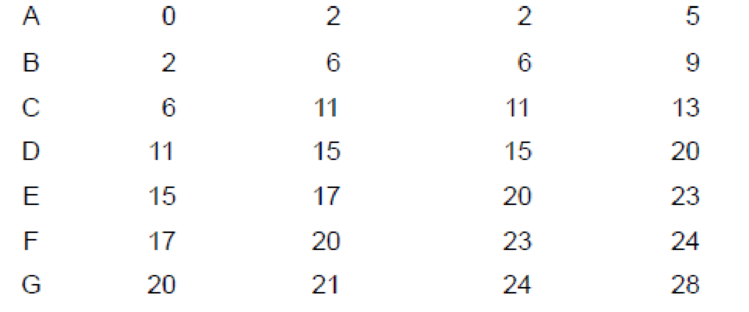

Ch. 16 - Prob. 11DRQCh. 16 - What general trade-offs are involved in sequencing...Ch. 16 - Prob. 2TSCh. 16 - Prob. 3TSCh. 16 - One approach that can be effective in reducing the...Ch. 16 - Doctors and dentists offices frequently schedule...Ch. 16 - Prob. 3CTECh. 16 - Use the assignment method to determine the best...Ch. 16 - Rework Problem 1, treating the numbers in the...Ch. 16 - Assign trucks to delivery routes so that total...Ch. 16 - Develop an assignment plan that will minimize...Ch. 16 - Use the assignment method to obtain a plan that...Ch. 16 - The following table contains information...Ch. 16 - Using the information presented in the following...Ch. 16 - The following table shows orders to be processed...Ch. 16 - A wholesale grocery distribution center uses a...Ch. 16 - The times required to complete each of eight jobs...Ch. 16 - Prob. 11PCh. 16 - A shoe repair operation uses a two-step sequence...Ch. 16 - The following schedule was prepared by the...Ch. 16 - The production manager must determine the...Ch. 16 - A foreman has determined processing times at a...Ch. 16 - Given the information in the following table,...Ch. 16 - Given the following information on job times and...Ch. 16 - Prob. 18PCh. 16 - The following table contains order-dependent setup...Ch. 16 - The following table contains order-dependent setup...Ch. 16 - Prob. 21PCh. 16 - Given this information on planned and actual...Ch. 16 - Given the following data on inputs and outputs at...Ch. 16 - Determine the minimum number of workers needed,...Ch. 16 - Determine the minimum number of workers needed,...Ch. 16 - Determine the minimum number of workers needed,...Ch. 16 - Prob. 1CQ

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, operations-management and related others by exploring similar questions and additional content below.Similar questions

- وبة واضافة هذه القيمة الى القيم Ex: Assign each job for each worker at minimum total Cost عمل لكل عامل وبأقل كلفة ممكنة obs الأعمال Workors العمال J1 J2 J3 J4 W₁ 15 13 14 12 W2 11 12 15 13 W3 13 12 10 11 W4 15 17 14 16arrow_forwardThe average completion time (flow time) for the sequence developed using the FCFS rule = 11.75 days (round your response to two decimal places). The percentage utilization for the sequence developed using the FCFS rule = 42.55 % (enter your response as a percentage rounded to two decimal places). b) Using the SPT (shortest processing time) decision rule for sequencing the jobs, the order is (to resolve a tie, use the order in which the jobs were received): An Alabama lumberyard has four jobs on order, as shown in the following table. Today is day 205 on the yard's schedule. In what sequence would the jobs be ranked according to the decision rules on the left: Job Due Date A 212 B 209 C 208 D 210 Duration (days) 6 3 3 8 Sequence 1 Job B 2 3 4 A D The average tardiness (job lateness) for the sequence developed using the SPT rule = 5.00 days (round your response to two decimal places). The average completion time (flow time) for the sequence developed using the SPT rule = 10.25 days…arrow_forwardWith the aid of examples, fully discuss any five (5) political tactics used in organisations.arrow_forward

- a. With the aid of examples, define discrimination. b. Fully discuss any four (4) types of discrimination in the workplacearrow_forwardRead the Following Extract and Answer the Questions that Follows:The word politics has a somewhat negative connotation. It suggests that someone is attempting touse means or to gain ends that are not sanctioned by the organisation. Political behaviour, as we’vedefined it is quite neutral. Similarly, power is not inherently negative. Whether a person viewspower and politics as unsavoury topics depends on several considerations, most important perhapsbeing where the individual stands on a specific issue in each situation. Nonetheless, most managersare reluctant to admit to political character of their own work settings.Discuss any Five (5) Political tactics you know.arrow_forwardDescribe current features of Cigna Accredo pharmacy own appraisal forms and compare the system used against the textbook’s description of desirable features of appraisal forms. What improvements would you recommend and why?arrow_forward

- Provide a recommendation of a combination of different methods of performance data that could be used to arrive at an overall score for each person being rated in cigna Accredo pharmacy. Explain the comprehensive system you have recommended and why you have chosen this combination of tools. Support your answer with research.arrow_forwardAlready got wrong answer Plz Don't use chatgptarrow_forwardThe RTY calculation for the following process steps would be: A ➡ ○ A.YA+YB+YC+YD OB. (YA)(YB)(YCYD) OC. ((YA+YB+YC+YD)/4)*4 ○ D. (1/YA)+(1/YB)+(1/YC)+YD B C Darrow_forward

- Can you guys help me with this? 1. What did you learn about the case, the concepts of transformational leadership; transactional leadership; Herzberg's Two Factors; Maslow's Hierarchy of needs theories that been applied through the case? Here is the case: Theranos (2003-2018):Overview: Theranos promised to revolutionize blood testing but was exposed formisleading claims about its technology, leading to its collapse 2. What did you learn about the case between Elon Musk and Twitter, the concepts of transformational leadership; transactional leadership; Herzberg's Two Factors Theory; Maslow's Hierarchy of needs theories that been applied through the case? 3. What did you learn about the case of Blockbuster's decline and their failure to adapt with digital streaming, the concepts of autocratic leadership; transactional leadership; Herzberg's Two Factors; Maslow's Hierarchy of needs theories that been applied through the case?arrow_forwardCan you guys help me with this? 1. What did you learn about the case, the concepts of transformational leadership; transactional leadership; Herzberg's Two Factors; and Maslow's Hierarchy of needs theories that have been applied through the case? Here is the case: The COVID-19 Pandemic Response (2020-Present): Overview: Global leaders had to navigate an unprecedented health crisis, balancingpublic health needs with economic pressures. 2. What did you learn about the case, the concepts of transformational leadership; transactional leadership; Herzberg's Two Factors Theory; and Maslow's Hierarchy of Needs theories that have been applied through the case? Here's the case: Google Glass (2013):Overview: Google launched its augmented reality glasses with high expectations, butprivacy concerns and limited functionality led to poor adoption 3. What did you learn about the case of Kodak's failure to keep up with digital photography, the concepts of autocratic leadership; transformational…arrow_forwardWith the above information do the following:1. Based on the From-To chart presented develop an ActivityRelationship Chart for this operation.2. Develop a Space-Relationship Diagram for this operation.3. Evaluate the actual layout using the “Distance Traveled byProduct” technique discussed in class (use rectilinear distance inall calculations).4. Develop two layout improvement alternatives.5. Evaluate alternatives using the “Distance Traveled by Product”technique discussed in class (use rectilinear distance in allcalculations).6. Make a layout recommendation based on alternatives evaluatedarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.

Inventory Management | Concepts, Examples and Solved Problems; Author: Dr. Bharatendra Rai;https://www.youtube.com/watch?v=2n9NLZTIlz8;License: Standard YouTube License, CC-BY