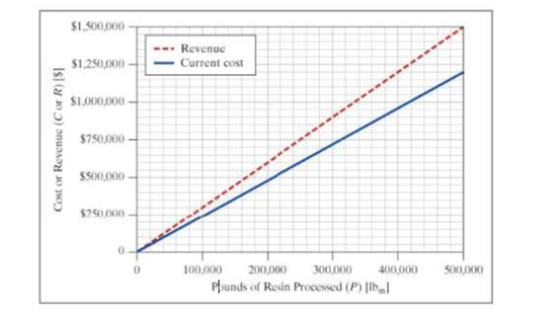

You are an engineer for a plastics manufacturing company. In examining cost-saving measures, your team has brainstormed the following ideas (labeled Idea A and Idea B). It is your responsibility to evaluate these ideas and recommend which one to pursue. You have been given a graph of the current process. A copy of this graph has been provided online; you may use one of these graphs, or use graph paper as directed by your instructor.

- a. What is the selling price of the product?

Current Cost: The current process has been running for a number of years, so there are no initial fixed costs to consider.

In the operating costs, the process requires the following:

|

$2.00/pound-mass of resin |

|

S0.15/pound-mass of resin |

|

$0.10/pound-mass of resin |

- b. There is also a cost associated with taking the scrap material to the landfill. Using the total cost determined from the graph, find the cost of landfill, in dollars per pound-mass of resin.

Idea A: Your customer will allow you to use regrind (reprocessed plastic) in the parts instead of 100% virgin plastic. Your process generates 10% scrap. Evaluate using all your scrap materials as regrind, with the regrind processed at your plant.

- c. You will need to purchase a regrind machine to process the plastic, estimated at a cost of $100,000. Using the regrind will alter the following costs, which account for using 10% scrap material:

| ■ Material cost: | $1.80/pound-mass of resin |

| ■ Energy cost: | $0.16/pound-mass of resin |

| ■ Labor cost: | $0.11/pound-mass of resin |

This idea will eliminate the landfill charge required in the current process (see part [b]). Draw the total cost curve for Idea A on the graph or on a copy.

- d. How long (in pounds of resin processed) before the company reaches breakeven on Idea A?

- e. At what minimum level of production (in pound-mass of resin processed) will Idea A begin to generate more profit than the current process?

Your customer will allow you to use regrind (reprocessed plastic) in the parts instead of 100% virgin plastic. Evaluate using 25% regrind purchased from an outside vendor.

- f. Using the regrind from the other company will alter the following costs, which account for using 25% scrap material purchased from the outside vendor:

| ■ Material cost: | $1.85/pound-mass of resin |

| ■ Energy cost: | $0.15/pound-mass of resin |

| ■ Labor cost: | $0.11/pound-mass of resin |

This idea will eliminate the landfill charge required in the current process (see part [b]) and will not require the purchase of a regrind machine as discussed in Idea A. Draw the total cost curve for Idea B on the graph or on a copy.

- g. At what minimum level of production (in pound-mass of resin processed) will Idea B begin to generate more profit than the current process?

- h. At a production level of 500,000 pound-mass of resin, which Idea (A, B, or neither) gives the most profit over the current process?

- i. If the answer to part (h) is neither machine, list the amount of profit generated by the current process at 500,000 pound-mass of resin. If the answer to part (h) is Idea A or Idea B, list the amount of profit generated by that idea at 500,000 pound-mass of resin.

Want to see the full answer?

Check out a sample textbook solution

Chapter 13 Solutions

Thinking Like an Engineer: An Active Learning Approach (4th Edition)

Additional Engineering Textbook Solutions

Elementary Surveying: An Introduction To Geomatics (15th Edition)

Thermodynamics: An Engineering Approach

Modern Database Management

Concepts Of Programming Languages

Management Information Systems: Managing The Digital Firm (16th Edition)

Automotive Technology: Principles, Diagnosis, And Service (6th Edition) (halderman Automotive Series)

- Correct answer is written below. Detailed and complete solution only with fbd. I will upvote, thank you.arrow_forwardCorrect answer is written below. Detailed and complete solution only. I will upvote, thank you.arrow_forwardCorrect answer is written below. Detailed and complete solution with fbd only. I will upvote, thank you.arrow_forward

- Correct answer is written below. Detailed and complete solution only. I will upvote, thank you.arrow_forwardCorrect answer is written below. Detailed and complete solution with fbd only. I will upvote, thank you.arrow_forwardCorrect answer is written below. Detailed and complete solution only. I will upvote, thank you.arrow_forward

- Correct answer is written below. Detailed and complete solution only. I will upvote, thank you.arrow_forwardCorrect answer is written below. Detailed and complete solution only. I will upvote, thank you.arrow_forwardCorrect answer is written below. Detailed and complete solution with fbd only. I will upvote, thank you. Prefferably handwritten solution pleasearrow_forward

- Correct answer is written below. Detailed and complete solution with fbd only. I will upvote, thank you. Prefferably handwritten solution pleasearrow_forwardCorrect answer is written below. Detailed and complete solution only. I will upvote, thank you.arrow_forwardCorrect answer is written below. Detailed and complete solution with fbd only. I will upvote, thank you. Prefferably handwritten solution pleasearrow_forward

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY