Concept explainers

(a)

Find the acceleration of block A for each system.

(a)

Answer to Problem 12.15P

The acceleration of block A for system 1 is

The acceleration of block A for system 2 is

The acceleration of block A for system 1 is

Explanation of Solution

Calculation:

Sketch the general diagram of systems as shown in Figure (1).

Write total length of cable connecting block A and block B.

Here,

Differentiate Equation (1) with respect to t to write velocity of the blocks.

Here,

Differentiate Equation (2) with respect to t to write acceleration of the blocks.

First of all check the required static friction with static friction to maintain equilibrium.

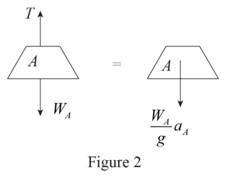

Sketch the free body diagram and kinetic diagram of block A as shown in Figure (2).

Refer Figure (2).

Consider downward direction as positive.

Apply Newton’s law of motion along y-axis.

Here, T is the tension in the cable,

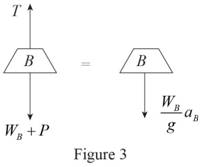

Sketch the free body diagram and kinetic diagram of block B as shown in Figure (3).

Refer Figure (3).

Consider downward direction as positive.

Apply Newton’s law of motion along y-axis.

Find the equation of acceleration of block A.

Here, T is the tension in the cable,

Substitute

The initial velocity of block A is zero.

Find the equation of velocity of block A using kinematics:

Here,

Substitute At

Find the equation of time required for block A to reach any velocity.

Find the acceleration of block A

Substitute 200 lb for

Therefore, the acceleration of block A for system 1 is

Find the acceleration of block A

Substitute 200 lb for

Therefore, the acceleration of block A for system 2 is

Find the acceleration of block A

Substitute 2200 lb for

Therefore, the acceleration of block A for system 2 is

(b)

Find the velocity of block A for each system after it has moved through 10 ft

(b)

Answer to Problem 12.15P

The velocity of block A for system 1 after it has moved through 10 ft is

The velocity of block A for system 2 after it has moved through 10 ft is

The velocity of block A for system 3 after it has moved through 10 ft is

Explanation of Solution

Calculation:

Find the velocity of block A for system 1

Substitute

Thus, the velocity of block A for system 1 after it has moved through 10 ft is

Find the velocity of block A for system 2

Substitute

Thus, the velocity of block A for system 2 after it has moved through 10 ft is

Find the velocity of block A for system 3

Substitute

Thus, the velocity of block A for system 3 after it has moved through 10 ft is

(c)

Find the time required for block A to reach a velocity of 20 ft/s

(c)

Answer to Problem 12.15P

The time required for block A for system 1 to reach a velocity of 20 ft/s is

The time required for block A for system 2 to reach a velocity of 20 ft/s is

The time required for block A for system 3 to reach a velocity of 20 ft/s is

Explanation of Solution

Calculation:

Find the time required for block A for system 1

Substitute

Thus, the time of required for block A for system 1 to reach a velocity of 20 ft/s is

Find the time required for block A for system 2

Substitute

Thus, the time of required for block A for system 2 to reach a velocity of 20 ft/s is

Find the time required for block A for system 3

Substitute

Thus, the time of required for block A for system 3 to reach a velocity of 20 ft/s is

Want to see more full solutions like this?

Chapter 12 Solutions

VEC MECH 180-DAT EBOOK ACCESS(STAT+DYNA)

- reaction at a is 1.6 wL (pos) handwritten solutions only please. correct answers upvotedarrow_forward1 8 4 Add numbers so that the sum of any row or column equals .30 Use only these numbers: .1.2.3.4.5.6.10.11.12.12.13.14.14arrow_forwardUppgift 2 (9p) I77777 20 kN 10 kN/m 4 [m] 2 2 Bestäm tvärkrafts- och momentdiagram för balken i figuren ovan. Extrempunkter ska anges med både läge och värde i diagrammen.arrow_forward

- **Problem 8-45.** The man has a mass of 60 kg and the crate has a mass of 100 kg. If the coefficient of static friction between his shoes and the ground is \( \mu_s = 0.4 \) and between the crate and the ground is \( \mu_c = 0.3 \), determine if the man is able to move the crate using the rope-and-pulley system shown. **Diagram Explanation:** The diagram illustrates a scenario where a man is attempting to pull a crate using a rope-and-pulley system. The setup is as follows: - **Crate (C):** Positioned on the ground with a rope attached. - **Rope:** Connects the crate to a pulley system and extends to the man. - **Pulley on Tree:** The rope runs over a pulley mounted on a tree which redirects the rope. - **Angles:** - The rope between the crate and tree forms a \(30^\circ\) angle with the horizontal. - The rope between the tree and the man makes a \(45^\circ\) angle with the horizontal. - **Man (A):** Pulling on the rope with the intention of moving the crate. This arrangement tests the…arrow_forwardplease solve this problems follow what the question are asking to do please show me step by steparrow_forwardplease first write the line action find the forces and them solve the problem step by steparrow_forward

- please solve this problem what the problem are asking to solve please explain step by step and give me the correct answerarrow_forwardplease help me to solve this problem step by steparrow_forwardplease help me to solve this problem and determine the stress for each point i like to be explained step by step with the correct answerarrow_forward

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY