Concept explainers

a. One hundred twenty units of end item Z are needed at the beginning of week 7. Prepare a material requirements plan for component C. Take into account that on hand there are 40 units of Z, 70 units of A, 100 units of B, and 30 units of C. Also, there is a

b. Ninety-five units of end item E are needed at the beginning of week 7. Prepare a material requirements plan for component D. Take into account that 5 units of E are currently on hand, as well as 50 units of B, 100 units of C, and 80 units of D. Also, 30 units of C have been outsourced and are expected to arrive in week 4. Lead times are two weeks for E and C. and one week for the other components. Assume lot-for-lot ordering except for D. where multiples of 40 must be used.

a)

To prepare: A material requirements plan for Component C.

Introduction: Materials Requirement Planning (MRP) is the planning or scheduling system, which can be used in the manufacturing process. It is used to plan the number of items required to produce one unit of finished goods (end item)

Explanation of Solution

Given information:

120 units of end item (Z) are required at the beginning of Week 7. It is given that 40 units of Component Z, 100 units of Component B, 70 units of Component A, and 30 units of Component C are available on hand. Scheduled receipt is 20 units of Component C in Week 4. Lead-time is given as 2 weeks for Component Z and Component B and 1 week for other components. Lot size is lot-for-lot.

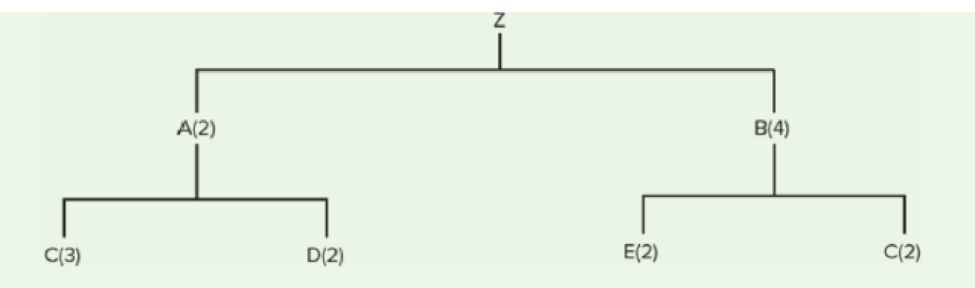

In addition to the above information, the following diagram is given:

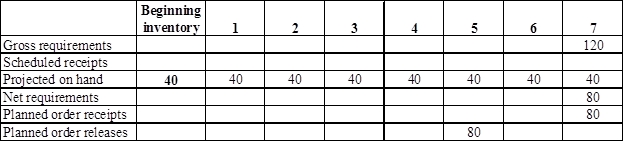

Prepare a Material Requirement Plan (MRP) for Component Z:

- Gross requirement is given as 120 units at the beginning of Week 7.

- On-hand inventory is 40 units. It remains same until Week 6, as there is no demand.

- Net requirement can be calculated by subtracting the projected on hand inventory of previous week from the gross requirement of current week.

- 80 units are required at the beginning of Week 7. Hence, they need to order for 80 units (as the lot size is lot-for-lot) before two weeks (as the lead-time is 2 weeks), which means on Week 5.

- Projected on-hand inventory is calculated by adding the scheduled receipts and the value attained by subtracting gross requirements from the sum of projected on-hand of previous week and planned order receipt of previous week.

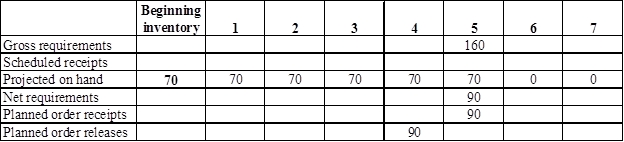

Prepare a Material Requirement Plan (MRP) for Component A (2):

- Component Z is the parent item of Component A (2). As the number of Component A is 2, the planned order release should be multiplied with 2 to determine the gross requirement of Component A.

- On-hand inventory is 70 units. It remains same until Week 4, as there is no demand.

- Net requirement can be calculated by subtracting the projected on hand inventory of previous week from the gross requirement of current week.

- 90 units are required at the beginning of Week 5. Hence, they need to order for 90 units (as the lot size is lot-for-lot) on previous week (as the lead-time is 1 weeks), which means on Week 4.

- Projected on-hand inventory is calculated by adding the scheduled receipts and the value attained by subtracting gross requirements from the sum of projected on-hand of previous week and planned order receipt of previous week.

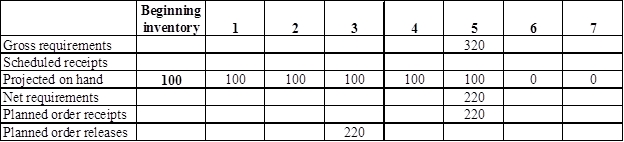

Prepare a Material Requirement Plan (MRP) for Component B (4):

- Component Z is the parent item of Component B (4). As the number of Component B is 4, the planned order release should be multiplied with 4 to determine the gross requirement of Component B.

- On-hand inventory is 100 units. It remains same until Week 4, as there is no demand.

- Net requirement can be calculated by subtracting the projected on hand inventory of previous week from the gross requirement of current week.

- 220 units are required at the beginning of Week 5. Hence, they need to order for 220 units (as the lot size is lot-for-lot) on two weeks before (as the lead-time is 2 weeks), which means on Week 3.

- Projected on-hand inventory is calculated by adding the scheduled receipts and the value attained by subtracting gross requirements from the sum of projected on-hand of previous week and planned order receipt of previous week.

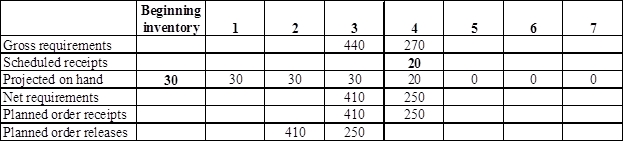

Prepare a Material Requirement Plan (MRP) for Component C (3) and C (2):

- Component A (2) is the parent item of Component C (3) and Component B (4) is the parent item of Component C (2). As the number of Component C is 3, the planned order release of Component A should be multiplied with 3 to determine the gross requirement of Component C. The same should be followed for Component C (2) with its parent item B (4).

- On-hand inventory is 30 units. It remains same until Week 3, as there is no demand.

- Net requirement can be calculated by subtracting the projected on hand inventory of previous week from the gross requirement of current week.

- 410 units are required at the beginning of Week 3. Hence, they need to order for 410 units (as the lot size is lot-for-lot) on previous week (as the lead-time is 1 week), which means on Week 2.

- Projected on-hand inventory is calculated by adding the scheduled receipts and the value attained by subtracting gross requirements from the sum of projected on-hand of previous week and planned order receipt of previous week.

- Projected on-hand inventory is calculated by adding the scheduled receipts and the value attained by subtracting gross requirements from the sum of projected on-hand of previous week and planned order receipt of previous week.

b)

To prepare: A material requirements plan for Component D.

Introduction: Materials Requirement Planning (MRP) is the planning or scheduling system, which can be used in the manufacturing process. It is used to plan the number of items required to produce one unit of finished goods (end item)

Explanation of Solution

Given information:

95 units of end item (E) are required at the beginning of Week 7. It is given that 5 units of Component E, 50 units of Component B, 80 units of Component D, and 100 units of Component C are available on hand. Scheduled receipt is 30 units of Component C in Week 4. Lead-time is given as 2 weeks for Component E and Component C and 1 week for other components. Lot size is lot-for-lot for all the components except Component D. Lot size for Component C is multiples of 40.

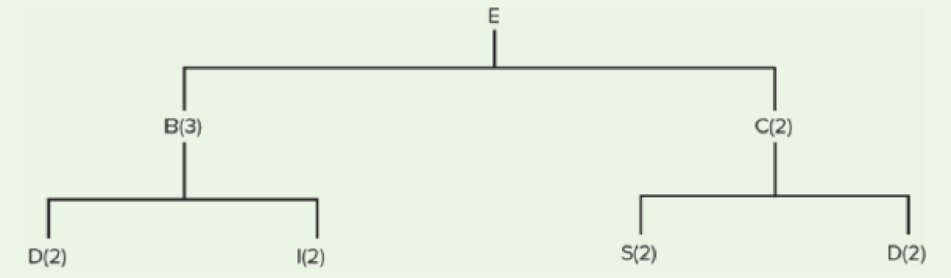

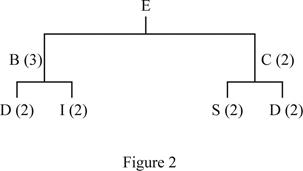

In addition to the above information, the following diagram is given:

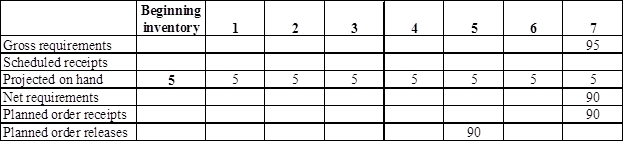

Prepare a Material Requirement Plan (MRP) for Component E:

- Gross requirement is given as 95 units at the beginning of Week 7.

- On-hand inventory is 5 units. It remains same until Week 6, as there is no demand.

- Net requirement can be calculated by subtracting the projected on hand inventory of previous week from the gross requirement of current week.

- 90 units are required at the beginning of Week 7. Hence, they need to order for 90 units (as the lot size is lot-for-lot) before two weeks (as the lead-time is 2 weeks), which means on Week 5.

- Projected on-hand inventory is calculated by adding the scheduled receipts and the value attained by subtracting gross requirements from the sum of projected on-hand of previous week and planned order receipt of previous week.

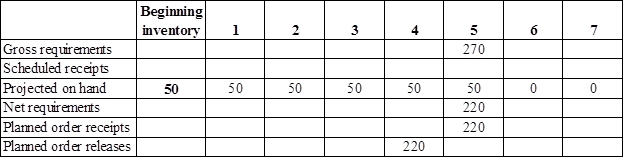

Prepare a Material Requirement Plan (MRP) for Component B (3):

- Component E is the parent item of Component B (3). As the number of Component B is 3, the planned order release should be multiplied with 3 to determine the gross requirement of Component 3.

- On-hand inventory is 50 units. It remains same until Week 4, as there is no demand.

- Net requirement can be calculated by subtracting the projected on hand inventory of previous week from the gross requirement of current week.

- 220 units are required at the beginning of Week 5. Hence, they need to order for 220 units (as the lot size is lot-for-lot) on previous week (as the lead-time is 1 weeks), which means on Week 4.

- Projected on-hand inventory is calculated by adding the scheduled receipts and the value attained by subtracting gross requirements from the sum of projected on-hand of previous week and planned order receipt of previous week.

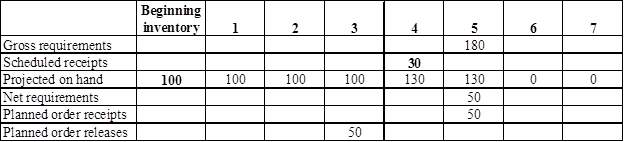

Prepare a Material Requirement Plan (MRP) for Component C (2):

- Component E is the parent item of Component C (2). As the number of Component C is 2, the planned order release should be multiplied with 2 to determine the gross requirement of Component C.

- On-hand inventory is 100 units. It remains same until Week 3, as there is no demand. Scheduled receipts of 30 units arrived on Week 4. Hence, the on-hand inventory is 130 units on Week 4.

- Net requirement can be calculated by subtracting the projected on hand inventory of previous week from the gross requirement of current week.

- 50 units are required at the beginning of Week 5. Hence, they need to order for 50 units (as the lot size is lot-for-lot) on two weeks before (as the lead-time is 2 weeks), which means on Week 3.

- Projected on-hand inventory is calculated by adding the scheduled receipts and the value attained by subtracting gross requirements from the sum of projected on-hand of previous week and planned order receipt of previous week.

- Projected on-hand inventory is calculated by adding the scheduled receipts and the value attained by subtracting gross requirements from the sum of projected on-hand of previous week and planned order receipt of previous week.

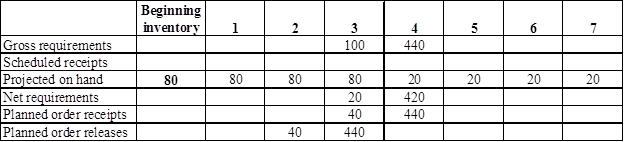

Prepare a Material Requirement Plan (MRP) for Component D (2) and D (2):

- Component B (3) is the parent item of Component D (2) and Component C (2) is the parent item of Component D (2). As the number of Component D is 2, the planned order release of Component B should be multiplied with 2 to determine the gross requirement of Component D. The same should be followed for Component D (2) with its parent item C (2).

- On-hand inventory is 80 units. It remains same until Week 3, as there is no demand.

- Net requirement can be calculated by subtracting the projected on hand inventory of previous week from the gross requirement of current week.

- 20 units are required at the beginning of Week 3. Hence, they need to order for 40 units (as the lot size is multiples of 40) on previous week (as the lead-time is 1 week), which means on Week 2.

- Projected on-hand inventory is calculated by adding the scheduled receipts and the value attained by subtracting gross requirements from the sum of projected on-hand of previous week and planned order receipt of previous week.

- Projected on-hand inventory is calculated by adding the scheduled receipts and the value attained by subtracting gross requirements from the sum of projected on-hand of previous week and planned order receipt of previous week.

Want to see more full solutions like this?

Chapter 12 Solutions

Loose-leaf for Operations Management (The Mcgraw-hill Series in Operations and Decision Sciences)

Additional Business Textbook Solutions

Horngren's Accounting (12th Edition)

Principles of Microeconomics (MindTap Course List)

Principles Of Taxation For Business And Investment Planning 2020 Edition

Essentials of MIS (13th Edition)

Marketing: An Introduction (13th Edition)

Gitman: Principl Manageri Finance_15 (15th Edition) (What's New in Finance)

- Answer all parts to question 4 and show all workingarrow_forward1) View the video Service Processing at BuyCostumes (10.41 minutes, Ctrl+Click on the link); what are your key takeaways (tie to one or more of the topics discussed in Chapter 3) after watching this video. (viddler.com/embed/a6b7054c) Note: As a rough guideline, please try to keep the written submission to one or two paragraphs. 2) Orkhon Foods makes hand-held pies (among other products). The firm’s weekly sales of hand-held pies over the past seven weeks are given in the table. The firm’s operations manager, Amarjargal, wants to forecast sales for week 8. Weeks Sales of hand-held pies(000s) 1 19 2 18 3 17 4 20 5 18 6 22 7 20 Forecast the week 8 sales using the following approaches: a) Naïve approach b) 5-month moving average c) 3-month weighted moving average using the following weights: 0.50 for week 7, 0.30 for week 6, and 0.20 for week 5. d) Exponential smoothing using a smoothing constant of 0.30, assume a week 2…arrow_forwardWhat area of emotional intelligence refers to the ability to manage your emotions, particularly in stressful situations, and maintain a positive outlook despite setbacks? relationship management self awareness social awareness self managementarrow_forward

- What area of emotional intelligence refers to the ability to manage your emotions, particularly in stressful situations, and maintain a positive outlook despite setbacks? relationship management self awareness social awareness self managementarrow_forwardThis area of emotional intelligence describes your ability to not only understand your strengths and weaknesses but to recognize your emotions and their effect on you and your team’s performance self management self awareness relationship management social awarenessarrow_forwardEmotional intelligence is defined as the ability to understand and manage your emotions, as well as recognize and influence the emotions of those around you. True Falsearrow_forward

- At the Ford automobile Highland plant, assume the one-millionth vehicle was produced in 1916 at a cost of $8084 (in 2013 US$), by how much did the Ford company reduce his cost with each doubling of cumulative output from 1916 to 1927?arrow_forwardAt the Ford automobile Highland plant,in 1913, how long did the average worker stay with the plant and what was the average tenure of a worker?arrow_forwardCommunity Federal Bank in Dothan, Alabama, recently increased its fees to customers who use employees as tellers. Management is interested in whether its new tee policy has increased the number of customers now using its automatic teller machines to that point that more machines are required. The following table provides the number of automatic teller transactions by week. Use trend projection with regression to forecast usage for weeks 13-16.arrow_forward

- Davison Electronics manufactures three LED television monitors, identified as Model A, Model B, and Model C. Davison Electronics four manufacturing plants. Each model has its lowest possible production cost when produced at Plant 1. However, Plant 1 does not have the capacity to handle the total production of all three models. As a result, at least some of the production must be routed to the other manufacturing plants. The following table shows the minimum production requirements for next month, the plant capacities in units per month, and the production cost per unit at each plant: Model Production Cost per Unit Minimum Production Requirements Plant 1 Plant 2 Plant 3 Plant 4 A $25 $28 $37 $34 48,000 B $26 $35 $36 $41 75,000 C $20 $31 $26 $23 60,000 Production Capacity 65,000 50,000 32,000 43,000 Davison’s objective is to determine the cost-minimizing production planarrow_forwardAnecdotally, entrepreneurs frequently encounter two critical dilemmas in managing human resources: the timing of hiring and the decision regarding hiring a generalist versus a specialist for their growing venture. Deciding when to expand a team is crucial, as premature hiring (i.e., hiring too soon) can strain resources, while delayed hiring (i.e., hiring too late) might hinder growth opportunities. Moreover, the choice between hiring a generalist or a specialist depends on the specific needs and stage of the venture, with each option presenting distinct advantages and challenges. To address these issues, a management scholar seeks to identify the factors shaping the hiring cycle throughout the entrepreneurial journey and to understand the criteria for choosing between generalists and specialists at various stages of a venture. The scholar has assembled a sample of 20 experienced South African entrepreneurs who have encountered both failure and success in the financial technology…arrow_forward3. [25 pts.] Four projects are available for investment. The projects require the cash flows and yield the net present values (NPV) (in millions) shown in the following table. Project id. 1 2 Cash outflow at time 0 (million Lira) 8 8 NPV (million Lira) 12 11 3 4 6 5 8 6 If 20 million Lira is available for investment at time 0, find the investment plan that maximizes NPV. All investments are required to be 0 or 1 (fractional investment values are not permitted). a. Formulate the mathematical model. (Write the decision variables, objective function and the constraints.) [10 pts.] b. Find the optimal solution by using Branch and Bound method (Draw the branch and bound tree clearly, write also lower bounds(LB)) (Left branches x=0, right branches x =1) [15 pts.].arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,MarketingMarketingISBN:9780357033791Author:Pride, William MPublisher:South Western Educational Publishing

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,MarketingMarketingISBN:9780357033791Author:Pride, William MPublisher:South Western Educational Publishing Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Contemporary MarketingMarketingISBN:9780357033777Author:Louis E. Boone, David L. KurtzPublisher:Cengage Learning

Contemporary MarketingMarketingISBN:9780357033777Author:Louis E. Boone, David L. KurtzPublisher:Cengage Learning