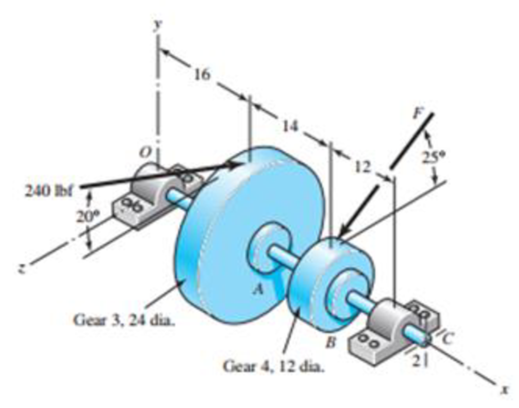

A gear-reduction unit uses the countershaft depicted in the figure. Find the two bearing reactions. The beatings are to be angular-contact ball bearings, having a desired life of 50 kh when used at 300 rev/min. Use 1.2 for the application factor and a reliability goal for the bearing pair of 0.96, assuming distribution data from manufacturer 2 in Table 11-6. Select the bearings from Table 11-2.

Problem 11-34

Dimensions in inches.

The reaction load at point O

The reaction load at point C

The bore diameter of angular contact ball bearing at point O.

The bore diameter of angular contact ball bearing at point C.

Answer to Problem 34P

The reaction load at point O is

The reaction load at point C is

The bore diameter of angular contact ball bearing at point O is 17 mm.

The bore diameter of angular contact ball bearing at point C is 35 mm.

Explanation of Solution

Write the expression for net force in y direction at point A.

Here, net force in y direction at point A is

Write the expression for net force in z direction at point A.

Write the expression for net force in y direction at point B.

Here, net force in y direction at point B is

Write the expression for net force in z direction at point B.

Here, net force in y direction at point B is

Write the expression for net torque on shaft.

Here, radius of gear at point A is

Write the expression for moment equilibrium in

Here, the moment is

Write the expression for moment equilibrium in

Here, the reaction force at C in z direction is

Write the expression for static force equilibrium in

Here, the force is

Write the expression for static force equilibrium in

Here, the force is

Write the expression for resultant force at point O.

Here, the resultant force at point O is

Write the expression for resultant force at point C.

Here, the resultant force at point C is

Write the expression for desired reliability.

Here, the desired reliability is

Write the expression for multiple of dating life.

Here, the multiple of rating life is

Write the expression for catalogue load rating at point O.

Here the catalogue load rating is

Write the expression for catalogue load rating at point C.

Here the catalogue load rating is

Conclusion:

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Thus the reaction load at point O is

Substitute

Thus the reaction load at point C is

Substitute 0.96 for

Substitute

Refer to Table 11-6 “Typical Weibull Parameters for Two Manufacturers” to obtain values of

Substitute

Refer to Table 11-2 “Dimensions and Load Ratings for Single-Row 02-Series Deep-Groove and Angular-Contact Ball Bearing” to obtain 17 mm bore size angular contact ball bearing corresponding to

Thus the Bore diameter of angular contact ball bearing at point O is 17 mm.

Substitute

Refer to Table 11-2 “Dimensions and Load Ratings for Single-Row 02-Series Deep-Groove and Angular-Contact Ball Bearing” to obtain 35 mm bore size angular contact ball bearing corresponding to

Thus Bore diameter of angular contact ball bearing at point C is 35 mm.

Want to see more full solutions like this?

Chapter 11 Solutions

Shigley's Mechanical Engineering Design (McGraw-Hill Series in Mechanical Engineering)

- 1.21 A one-dimensional plane wall is exposed to convective and radiative conditions at x = 0. The ambient and sur- rounding temperatures are T = 20°C and Tur = 40°C, respectively. The convection heat transfer coefficient is h=20 W/m² K, and the absorptivity of the exposed sur- face is α=0.78. Determine the convective and radiative heat fluxes to the wall at x = 0 if the wall surface tem- perature is T, = 24°C. Assume the exposed wall surface is gray, and the surroundings are large.arrow_forward1.12 You've experienced convection cooling if you've ever extended your hand out the window of a moving vehi- cle or into a flowing water stream. With the surface of your hand at a temperature of 30°C, determine the con- vection heat flux for (a) a vehicle speed of 40 km/h in air at -8°C with a convection coefficient of 40 W/m² K and (b) a velocity of 0.2 m/s in a water stream at 10°C with a convection coefficient of 900 W/m²K. Which condition would feel colder? Contrast these results with a heat flux of approximately 30 W/m² under normal room conditions.arrow_forwardPLEASE SOLVE STEP BY STEP WITHOUT ARTIFICIAL INTELLIGENCE OR CHATGPT SOLVE BY HAND STEP BY STEParrow_forward

- 1. A 40 lb. force is applied at point E. There are pins at A, B, C, D, and F and a roller at A. a. Draw a FBD of member EFC showing all the known and unknown forces acting on it. b. Draw a FBD of member ABF showing all the known and unknown forces acting on it. c. Draw a FBD of member BCD showing all the known and unknown forces acting on it. d. Draw a FBD of the entire assembly ADE showing all the known and unknown forces acting on it. e. Determine the reactions at A and D. f. Determine the magnitude of the pin reaction at C. 40 lbs. B A 6 in. 4 in. D F -5 in.4 in 4.arrow_forwardA crude oil of specific gravity0.85 flows upward at a volumetric rate of flow of 70litres per second through a vertical venturimeter,with an inlet diameter of 250 mm and a throat diameter of 150mm. The coefficient of discharge of venturimeter is 0.96. The vertical differences betwecen the pressure toppings is 350mm. i) Draw a well labeled diagram to represent the above in formation i) If the two pressure gauges are connected at the tapings such that they are positioned at the levels of their corresponding tapping points, determine the difference of readings in N/CM² of the two pressure gauges ii) If a mercury differential manometer is connected in place of pressure gauges, to the tappings such that the connecting tube up to mercury are filled with oil determine the difference in the level of mercury column.arrow_forwardCan you solve it analytically using laplace transforms and with Matlab code as well please. Thank Youarrow_forward

- Can you solve it analytically using laplace transforms and with Matlab code as well please. Thank You.arrow_forwardQ11. Determine the magnitude of the reaction force at C. 1.5 m a) 4 KN D b) 6.5 kN c) 8 kN d) e) 11.3 KN 20 kN -1.5 m- C 4 kN -1.5 m B Mechanical engineering, No Chatgpt.arrow_forwardplease help with this practice problem(not a graded assignment, this is a practice exam), and please explain how to use sohcahtoaarrow_forward

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY