Consider a combined gas–steam power plant that has a net power output of 280 MW. The pressure ratio of the gas-turbine cycle is 11. Air enters the compressor at 300 K and the turbine at 1100 K. The combustion gases leaving the gas turbine are used to heat the steam at 5 MPa to 350°C in a heat exchanger. The combustion gases leave the heat exchanger at 420 K. An open feedwater heater incorporated with the steam cycle operates at a pressure of 0.8 MPa. The condenser pressure is 10 kPa. Assuming isentropic efficiencies of 100 percent for the pump, 82 percent for the compressor, and 86 percent for the gas and steam turbines, determine (a) the mass flow rate ratio of air to steam, (b) the required rate of heat input in the combustion chamber, and (c) the thermal efficiency of the combined cycle.

(a)

The mass flow rate ratio of the air to the steam.

Answer to Problem 86P

The mass flow rate ratio of the air to the steam is

Explanation of Solution

Show the

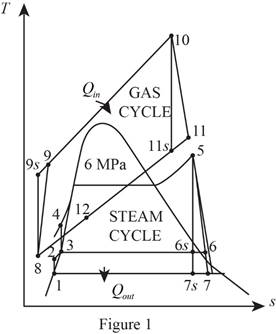

Refer Figure 1.

Consider the gas cycle (topping cycle) and their respective process states such as 8, 9,

At state 8:

The air enters the compressor at the temperature of

Refer Table A-17, “Ideal-gas properties of air”.

The enthalpy

Write the relative pressure and absolute pressure relation for the process 8-9-

Here, the relative pressure is

Write the formula for isentropic efficiency of compressor for the process 8-9-

Here, the enthalpy is

At state 10:

The air enters the turbine at the temperature of

Refer Table A-17, “Ideal-gas properties of air”.

The enthalpy

Write the relative pressure and absolute pressure relation for the process 10-11-

Write the formula for isentropic efficiency of gas turbine

At state 12: (heat exchanger)

The enthalpy

Refer Figure 1.

Consider the steam cycle (bottoming cycle) and their respective process states such as 1, 2, 3, 4, 5, 6,

At state 1: (Pump I inlet)

The water exits the condenser as a saturated liquid at the pressure of

Refer Table A-5, “Saturated water-Pressure table”.

The enthalpy

At state 2:

Write the formula for work done by the pump during process 1-2.

Here, the specific volume is

Write the formula for enthalpy

At state 3: (Pump II inlet)

The water exits the open feed water heater as a saturated liquid at the pressure of

Refer Table A-5, “Saturated water-Pressure table”.

The enthalpy

At state 4:

Write the formula for work done by the pump during process 3-4.

Here, the specific volume is

Write the formula for enthalpy

At state 5:

The steam enters the turbine as superheated vapour.

Refer Table A-6, “Superheated water”.

The enthalpy

At state

The steam expanded to the pressure of

The quality of water at state

The enthalpy at state

Here, the enthalpy is

Refer Table A-5, “Saturated water-Pressure table”.

Obtain the following properties corresponding to the pressure of

The isentropic efficiency of the steam turbine for the process 5-6-

At state

The steam enters the condenser at the pressure of

The quality of water at state

The enthalpy at state

Here, the subscript

Refer Table A-5, “Saturated water-Pressure table”.

Obtain the following properties corresponding to the pressure of

The isentropic efficiency of the steam turbine for the process 5-7-

Here, the subscript

Write the general energy rate balance equation.

Here, the rate of energy in is

Consider the heat exchanger operates on steady state. Hence, the rate of change in net energy of the system is zero.

The Equation (XVI) is reduced as follows for the heat exchanger.

Here, the mass flow rate of air is

Conclusion:

Substitute

Refer Table A-17, “Ideal-gas properties of air”.

The enthalpy

Substitute

Substitute

Refer Table A-17, “Ideal-gas properties of air”.

The enthalpy

Substitute

Substitute

Substitute

Substitute

Equation (VII).

Substitute

From Figure 1.

Substitute

Substitute

Equation (X).

Substitute

Substitute

Substitute

Equation (XIII).

Substitute

Substitute

Thus, the mass flow rate ratio of the air to the steam is

(b)

The required rate of heat input in the combustion chamber.

Answer to Problem 86P

The required rate of heat input in the combustion chamber is

Explanation of Solution

Refer Equation (XV).

Consider the open feed water heater operates on steady state. Hence, the rate of change in net energy of the system is zero.

Write the energy rate balance equation for open feed water heater.

Rewrite the Equation (XVII) in terms of mass fraction

Here, the mass fraction steam extracted from the turbine to the inlet mass of the boiler

Write the formula for work output of the steam turbine.

Write the formula for net work output of the steam cycle.

Write the formula for net work output of the gas cycle.

Write the formula for the net work output of the gas-steam cycle per unit mass of gas.

Write the formula for mass flow rate of air through the compressor.

Write the formula for rate of heat input to the combustion chamber.

Conclusion:

Substitute

Equation (XVIII).

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Equation (XXIV).

Thus, the required rate of heat input in the combustion chamber is

(c)

The thermal efficiency of the combined cycle.

Answer to Problem 86P

The thermal efficiency of the combined cycle is

Explanation of Solution

Write the formula for thermal efficiency.

Conclusion:

Substitute

Thus, the thermal efficiency of the combined cycle is

Want to see more full solutions like this?

Chapter 10 Solutions

Thermodynamics: An Engineering Approach

- I want to know the Milankovich orbital element constraint equation. Is it e*cos(i) = cos(argp), where e is eccentricity, i is inclination, and argp is arguement of periapsisarrow_forwardThe following data were taken during a one-hour trial run on a single cylinder, single acting, four-stroke diesel engine of cylinder diameter of 175 mm and stroke 225 mm , the speed being constant at 1000 rpm : Indicated mep: 5.5 barsDiam. of rope brake: 1066 mmLoad on brake: 400 NReading of balance: 27 NFuel consumed: 5.7 kgCalorific value: 44.2 MJ/kg Calculate the indicated power, brake power, specific fuel consumption per indicated kWh and per brake kWh , mechanical efficiency, indicated thermal and brake thermal efficiency.arrow_forwardmylabmastering.pearson.com Chapter 12 - Lecture Notes.pptx: (MAE 272-01) (SP25) DY... Document Sharing P Pearson MyLab and Mastering User Settings Part A P Course Home b Success Confirmation of Question Submission | bartleby A particle moves along an Archimedean spiral r = (80) ft, where 0 is given in radians. (Figure 1) If ė = = 4 rad/s and € = 5 rad/s², determine the radial component of the particle's velocity at the instant Express your answer to three significant figures and include the appropriate units. Figure y r = Α ? Vr = Value Units Submit Request Answer Part B Determine the transverse component of the particle's velocity. Express your answer to three significant figures and include the appropriate units. о MÅ ve = Value Submit Request Answer Part C Units ? 1 of 1 Determine the radial component of the particle's acceleration. Express your answer to three significant figures and include the appropriate units. Ar = (80) ft о ΜΑ Value Units ? = π/2 rad.arrow_forward

- Can you help me with a matlab code? I am trying to plot the keplerian orbital elements over time. I would usually find the orbit using cartesian system and then transform into keplerian orbital elements. Is there a way to directly integrate keplerian orbital elements?arrow_forwardmylabmastering.pearson.com Chapter 12 - Lecture Notes.pptx: (MAE 272-01) (SP25) DY... P Pearson MyLab and Mastering Scoresarrow_forwardK mylabmastering.pearson.com Chapter 12 - Lecture Notes.pptx: (MAE 272-01) (SP25) DY... P Pearson MyLab and Mastering Mastering Engineering Back to my courses Course Home Scores Course Homearrow_forwardK mylabmastering.pearson.com Chapter 12 - Lecture Notes.pptx: (MAE 272-01) (SP25) DY... P Pearson MyLab and Mastering Mastering Engineering Back to my courses Course Home Scores Course Homearrow_forwardChapter 12 - Lecture Notes.pptx: (MAE 272-01) (SP25) DY... Scoresarrow_forwardIn a single cylinder, four stroke, single acting gas engine, the cylinder diameter is 180 mm and the stroke is 350 mm . When running at 250 rpm , the mean area of the indicator diagram taken off the engine is 355 mm² , length of diagram 75 mm , scale of the indicator spring 90 kN/m sq per mm , and the number of explosions was counted to be 114 per minute. Calculate the indicated power. so i have already asked this question and got a good answer, however on step 4, i dont understand how they reached 18.43 KW. When i do the math provided, i get the answer 7195.566. Where am i going wrong? thanks StepsTo clarify how we determined the Indicated Power, I'll go over each step in detail. Step 1: Comprehending the Provided Information - Cylinder diameter (in meters) = 180 mm = 0.18 m - Stroke length (in meters) = 350 mm = 0.35 m - Engine speed = 250 rpm -Indicator diagram mean area = 355 mm² The diagram's length is 75 mm; its spring scale is 90 kN/m² per mm, or 90,000 N/m² per mm; and…arrow_forwardIn MATLAB, can you help me simulate an orbit under earth J2 perturbation with the Milankovich orbital elements? Also, can you check to see if they fit the Milankovich constraint equaiton?arrow_forward8. All of the members in the Warren truss of Figure 8 are of length 10 ft. Use the method of sections to determine the forces in the members BD,CD,CE. B A C D E F G 2000 lb 3000 lb 5000 lb Figure 8 Harrow_forwardAn acrobat is walking on a tightrope of length L =20.1 m attached to supports A and B at a distance of 20.0 m apart. The combined weight of the acrobat and his balancing pole is 900 N, and the friction between his shoes and the rope is large enough to prevent him from slipping. Neglecting the weight of the rope and any elastic deformation, determine the deflection (y) and the tension in portion AC and BC of the rope for values of x from 0.5 m to 10 m using 0.5 m increments. 1. Determine the maximum deflection (y) in the rope. 2. Plot tension of AC and BC vs. x (on the same plot with x on the x-axis). Turn in the plot and the table of x, TAC, and TBC (clearly label each). A C 20.0 m Barrow_forwardarrow_back_iosSEE MORE QUESTIONSarrow_forward_ios

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY