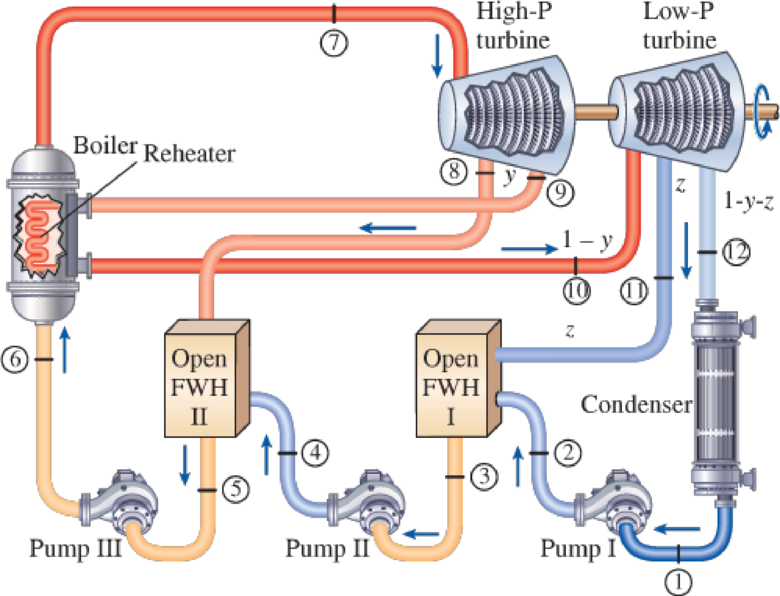

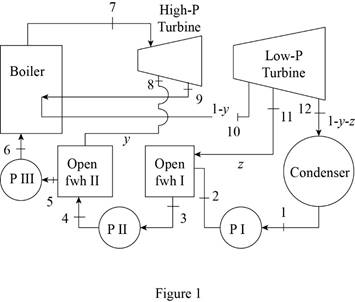

A steam power plant operates on an ideal reheat–regenerative Rankine cycle with one reheater and two open feedwater heaters. Steam enters the high-pressure turbine at 1500 psia and 1100°F and leaves the low- pressure turbine at 1 psia. Steam is extracted from the turbine at 250 and 40 psia, and it is reheated to 1000°F at a pressure of 140 psia. Water leaves both feedwater heaters as a saturated liquid. Heat is transferred to the steam in the boiler at a rate of 4 × 105 Btu/s. Show the cycle on a T-s diagram with respect to saturation lines, and determine (a) the mass flow rate of steam through the boiler, (b) the net power output of the plant, and (c) the thermal efficiency of the cycle.

FIGURE P10–62E

(a)

The mass flow rate of steam flowing through the boiler.

Answer to Problem 62P

The mass flow rate of steam flowing through the boiler is

Explanation of Solution

Draw the schematic layout of the given power plant that operates on an ideal reheat-regenerative Rankine cycle as shown in Figure 1.

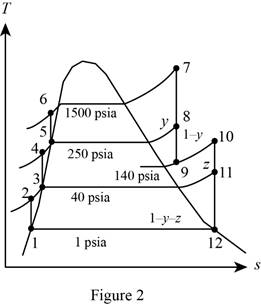

Draw the

Figure 2.

Here, water (steam) is the working fluid of the ideal regenerative Rankine cycle. The cycle involves three pumps.

Write the formula for work done by the pump during process 1-2.

Here, the specific volume is

Write the formula for enthalpy

Write the formula for work done by the pump during process 3-4.

Here, the specific volume is

Write the formula for enthalpy

Write the formula for work done by the pump during process 5-6.

Here, the specific volume is

Write the formula for enthalpy

Before reheating.

At state 9:

The steam expanded to the pressure of

After reheating.

At state 10:

The steam is reheated to the temperature of

At state 12:

The steam enters the condenser at the pressure of

The quality of water at state 12 is expressed as follows.

The enthalpy at state 12 is expressed as follows.

Here, the enthalpy is

Write the formula for heat in

Here, the mass fraction steam extracted from the turbine to the feed water entering the boiler via feed water heater-II

Write the general equation of energy balance equation.

Here, the rate of net energy inlet is

At steady state the rate of change of net energy of the system

Refer Equation (XI).

Write the energy balance equation for open feed water heater-II.

Rewrite the Equation (XII) in terms of mass fraction

Refer Equation (XI).

Write the energy balance equation for open feed water heater-I.

Rewrite the Equation (XIV) in terms of mass fraction

Write the formula for mass flow rate.

Here, the rate of heat input is

At state 1:

The water exits the condenser as a saturated liquid at the pressure of

Refer Table A-5E, “Saturated water-Pressure table”.

The enthalpy

At state 3: (Pump II inlet)

The water exits the open feed water heater-I as a saturated liquid at the pressure of

Refer Table A-5E, “Saturated water-Pressure table”.

The enthalpy

At state 5: (Pump III inlet)

The water exits the open feed water heater-II as a saturated liquid at the pressure of

Refer Table A-5E, “Saturated water-Pressure table”.

The enthalpy

At state 7: (H.P. Turbine inlet)

The steam enters the turbine as superheated vapor.

Refer Table A-6E, “Superheated water”.

The enthalpy

Refer Figure 2.

At state 8:

The steam is extracted at the pressure of

Refer Table A-6E, “Superheated water”.

The enthalpy

At state 9:

The steam is expanded at the pressure of

Refer Table A-6E, “Superheated water”.

The enthalpy

At state 10:

The steam is reheated to the temperature of

Refer Table A-6E, “Superheated water”.

The enthalpy

Refer Figure 2.

At state 11:

The steam is expanded at the pressure of

Refer Table A-6E, “Superheated water”.

The enthalpy

At state 12: (Condenser inlet)

The steam enters the condenser at the pressure of

Refer Table A-5E, “Saturated water-Pressure table”.

Obtain the following properties corresponding to the pressure of

Conclusion:

Substitute

Substitute

Substitute

Equation (III).

Substitute

Substitute

Equation (V).

Substitute

From Figure 2.

Substitute

Substitute

Equation (VIII).

Consider the open feed water heater-II alone.

Substitute

Equation (XIII).

Consider the open feed water heater-I alone.

Substitute

Substitute

Substitute

Substitute

Thus, the mass flow rate of steam flowing through the boiler is

(b)

The net power output of the plant.

Answer to Problem 62P

The net power output of the plant is

Explanation of Solution

Write the formula for net power output of the cycle per unit mass.

Write the formula for net power output of the cycle.

Here, the mass flow rate is

Conclusion:

Substitute

Substitute

Thus, the net power output of the plant is

(c)

The thermal efficiency of the cycle.

Answer to Problem 62P

The thermal efficiency of the cycle is

Explanation of Solution

Write the formula for thermal efficiency of the cycle

Conclusion:

Substitute

Thus, the thermal efficiency of the cycle is

Want to see more full solutions like this?

Chapter 10 Solutions

THERMODYNAMICS: ENG APPROACH LOOSELEAF

Additional Engineering Textbook Solutions

Starting Out with Java: From Control Structures through Objects (7th Edition) (What's New in Computer Science)

Fluid Mechanics: Fundamentals and Applications

Java How to Program, Early Objects (11th Edition) (Deitel: How to Program)

Database Concepts (8th Edition)

Mechanics of Materials (10th Edition)

Starting Out With Visual Basic (8th Edition)

- auto controlsarrow_forward1 Pleasearrow_forwardA spring cylinder system measures the pressure. Determine which spring can measure pressure between 0-1 MPa with a large excursion. The plate has a diameter of 20 mm. Also determine the displacement of each 0.1 MPa step.Spring power F=c x fF=Springpower(N)c=Spring constant (N/mm)f=Suspension (mm) How do I come up with right answer?arrow_forward

- A lift with a counterweight is attached to the ceiling. The attachment is with 6 stainless and oiled screws. What screw size is required? What tightening torque? - The lift weighs 500 kg and can carry 800 kg. - Counterweight weight 600 kg - Durability class 12.8 = 960 MPa- Safety factor ns=5+-Sr/Fm= 0.29Gr =0.55arrow_forwardKnowing that a force P of magnitude 750 N is applied to the pedal shown, determine (a) the diameter of the pin at C for which the average shearing stress in the pin is 40 MPa, (b) the corresponding bearing stress in the pedal at C, (c) the corresponding bearing stress in each support bracket at C. 75 mm 300 mm- mm A B P 125 mm 5 mm C Darrow_forwardAssume the B frame differs from the N frame through a 90 degree rotation about the second N base vector. The corresponding DCM description is: 1 2 3 4 5 6 9 # adjust the return matrix values as needed def result(): dcm = [0, 0, 0, 0, 0, 0, 0, 0, 0] return dcmarrow_forward

- Find the reaction at A and B The other response I got was not too accurate,I need expert solved answer, don't use Artificial intelligence or screen shot it solvingarrow_forwardNo chatgpt plsarrow_forwardSolve for the reaction of all the forces Don't use artificial intelligence or screen shot it, only expert should solvearrow_forward

- No chatgpt plsarrow_forwardA six cylinder petrol engine has a compression ratio of 5:1. The clearance volume of each cylinder is 110CC. It operates on the four-stroke constant volume cycle and the indicated efficiency ratio referred to air standard efficiency is 0.56. At the speed of 2400 rpm. 44000KJ/kg. Determine the consumes 10kg of fuel per hour. The calorific value of fuel average indicated mean effective pressure.arrow_forwardThe members of a truss are connected to the gusset plate as shown in (Figure 1). The forces are concurrent at point O. Take = 90° and T₁ = 7.5 kN. Part A Determine the magnitude of F for equilibrium. Express your answer to three significant figures and include the appropriate units. F= 7.03 Submit ? kN Previous Answers Request Answer × Incorrect; Try Again; 21 attempts remaining ▾ Part B Determine the magnitude of T2 for equilibrium. Express your answer to three significant figures and include the appropriate units. Figure T₂ = 7.03 C T2 |? KN Submit Previous Answers Request Answer × Incorrect; Try Again; 23 attempts remaining Provide Feedbackarrow_forward

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY