A steam power plant operates on an ideal regenerative Rankine cycle with two open feedwater heaters. Steam enters the turbine at 8 MPa and 550°C and exhausts to the condenser at 15 kPa. Steam is extracted from the turbine at 0.6 and 0.2 MPa. Water leaves both feedwater heaters as a saturated liquid. The mass flow rate of steam through the boiler is 24 kg/s. Show the cycle on a T-s diagram, and determine (a) the net power output of the power plant and (b) the thermal efficiency of the cycle.

(a)

The power output of plant.

Answer to Problem 52P

The power output of the plant is

Explanation of Solution

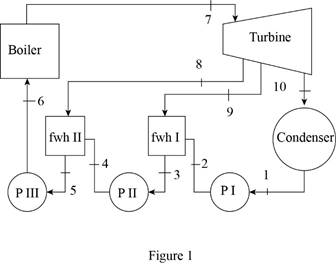

Draw the schematic diagram of the given ideal regenerative Rankine cycle as shown in

Figure 1.

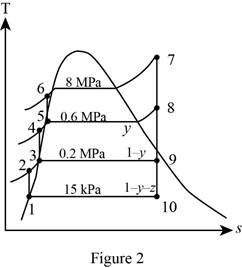

Draw the

Figure 2.

Here, water (steam) is the working fluid of the regenerative Rankine cycle. The cycle involves three pumps.

Write the formula for work done by the pump during process 1-2.

Here, the specific volume is

Write the formula for enthalpy

Write the formula for work done by the pump during process 3-4.

Here, the specific volume is

Write the formula for enthalpy

Write the formula for work done by the pump during process 5-6.

Here, the specific volume is

Write the formula for enthalpy

At state 9:

The steam expanded to the pressure of

The quality of water at the exit of the turbine (state 9) is expressed as follows.

The enthalpy at state 9 is expressed as follows.

Here, the enthalpy is

At state 10:

The steam enters the condenser at the pressure of

The quality of water at state 10 is expressed as follows.

The enthalpy at state 10 is expressed as follows.

Here, the subscript 10 indicates the process state 10.

Refer Figure 1 and 2.

Write the formula for heat in

Here, the mass fraction steam extracted from the turbine to the feed water entering the boiler via feed water heater-I

Write the general equation of energy balance equation.

Here, the rate of net energy inlet is

At steady state the rate of change of net energy of the system

Refer Equation (XIII).

Write the energy balance equation for open feed water heater-II.

Rewrite the Equation (XIV) in terms of mass fraction

Refer Equation (XIII).

Write the energy balance equation for open feed water heater-I.

Rewrite the Equation (XVI) in terms of mass fraction

Write the formula for net power output of the cycle per unit mass.

Write the formula for net power output of the cycle.

Here, the mass flow rate is

At state 1: (Pump I inlet)

The water exits the condenser as a saturated liquid at the pressure of

Refer Table A-5, “Saturated water-Pressure table”.

The enthalpy

At state 3: (Pump II inlet)

The water exits the open feed water heater-I as a saturated liquid at the pressure of

Refer Table A-5, “Saturated water-Pressure table”.

The enthalpy

At state 5: (Pump III inlet)

The water exits the open feed water heater-II as a saturated liquid at the pressure of

Refer Table A-5, “Saturated water-Pressure table”.

The enthalpy

At state 7:

The steam enters the turbine as superheated vapor.

Refer Table A-6, “Superheated water”.

The enthalpy

From Figure 2.

At state 8:

The steam expanded to the pressure of

Refer Table A-6, “Superheated water”.

The enthalpy

At state 9:

The steam expanded to the pressure of

Refer Table A-5, “Saturated water-Pressure table”.

Obtain the following properties corresponding to the pressure of

At state 10:

The steam enters the condenser at the pressure of

Refer Table A-5, “Saturated water-Pressure table”.

Obtain the following properties corresponding to the pressure of

Conclusion:

Substitute

Substitute

Substitute

Equation (III).

Substitute

Substitute

Equation (V).

Substitute

From Figure 1.

Substitute

Substitute

Equation (VIII).

Substitute

Substitute

Equation (X).

Consider the open feed water heater-II alone.

Substitute

Consider the open feed water heater-I alone.

Substitute

Substitute

Substitute

Substitute

Substitute

Thus, the power output of the plant is

(b)

The thermal efficiency of the cycle.

Answer to Problem 52P

The thermal efficiency of the cycle is

Explanation of Solution

Write the formula for thermal efficiency of the cycle

Conclusion:

Substitute

Thus, the thermal efficiency of the cycle is

Want to see more full solutions like this?

Chapter 10 Solutions

Thermodynamics: An Engineering Approach ( 9th International Edition ) ISBN:9781260092684

- What are examples of at least three (3) applications of tolerance fitting analysis.arrow_forwardThe primary material used in the production of glass products is silica sand. True or Falsearrow_forwardWhich one of the following is the most common polymer type in fiber-reinforced polymer composites? thermosets thermoplastics elastomers none of the abovearrow_forward

- Thermoset polymers can be recycled with little to no degradation in properties. True or Falsearrow_forwardTwo forces are applied as shown to a hook support. The magnitude of P is 38 N. 50 N 25° DG a 터 Using trigonometry, determine the required angle a such that the resultant R of the two forces applied to the support will be horizontal. The value of a isarrow_forwardNo chatgpt pls will upvotearrow_forward

- 101 the three shafts if the diameter ratio is 2 (D/d = 2)? Ans. na, tension = 1.21, na, bending = 1.19, na, torsion = 1.17. 6.32 A material with a yield strength of S₁ = 350 MPa is subjected to the stress state shown in Sketch c. What is the factor of safety based on the maximum shear stress and distortion energy theories? Ans. For MSST, n, = 11.67. 50 MPa 85 MPa 20 MPa 70 MPa Sketch c, for Problems 6.32 and 6.33arrow_forwardCan you draw the left view of the first orthographic projectionarrow_forwardImportant: I've posted this question twice and received incorrect answers. I've clearly stated that I don't require AI-generated working out. I need a genuine, expert-written solution with proper working. If you can't provide that, refer this question to someone who can please!. Note: Please provide a clear, step-by-step handwritten solution (no AI involvement). I require an expert-level answer and will assess it based on quality and accuracy with that I'll give it a thumbs up or down!. Hence, refer to the provided image for clarity. Double-check everything for correctness before submitting. Thank you!arrow_forward

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY