Concept explainers

ToysPlus, Inc.: MRP eXcel

Dale Long, vice president of manufacturing for ToysPlus, Inc., finished reading the weekly production report for the week ended September 16, 2016. Inventories were up once again, and service levels were lower than expected. Dale wondered why these problems could not be solved once and for all. Last year he had installed a new production and inventory

Dale took the report and walked to Andrea Meline’s office next door. Andrea had received her M.B.A. a few years ago from a prestigious business school and was now in charge of production control for the company. After exchanging the usual greetings, Dale asked Andrea why the latest figures were not better. Andrea responded, "Dale, we continue to get poor

BACKGROUND

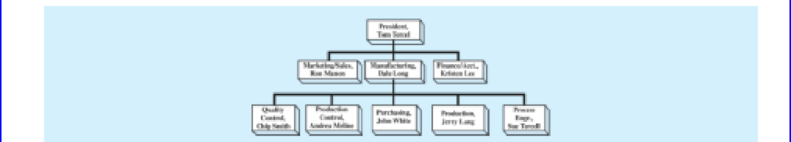

ToysPlus is a small, privately held company in the toy industry, with sales of about $20 million a year. The company was started in 1951, manufacturing an innovative line of plastic toys and trucks that were very durable and low-priced. Over the years it has added several lines of toys and is now making 22 different toys, including games, dolls, toy vehicles, and novelty items. The company has a typical functional organization, as shown in Exhibit 1.

EXHIBIT 1 Organization chart.

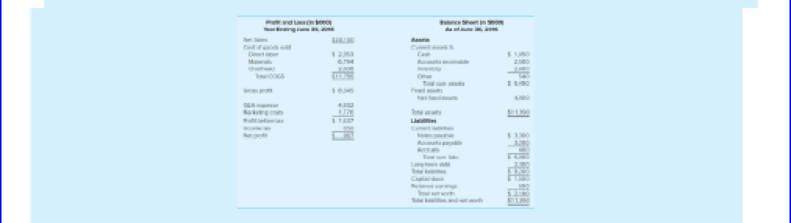

ToysPlus has had relatively poor financial results, as shown in Exhibit 2. Profits are averaging only 5 percent of sales, and return on assets is less than 10 percent. To improve the situation, the company has decided to make a major effort to reduce inventories and to improve customer service. In an effort to reduce costs, the company has begun to redesign the toys for manufacturability and automate its production process. The company feels that unit production costs could be reduced at least 5 percent per year by these efforts. The company also wants to achieve at least 15 inventory turns per year1 and a service level of 95 percent. Service level is defined as the percentage of orders filled within one week of customer order. The current service level is 90 percent.

EXHIBIT 2 Financial statements.

Manufacturing operations are organized around the different types of toys that are manufactured. Each type of toy has its own assembly line and its own dedicated workers. For example, three plastic toys—trucks, autos, and robots—are assembled on line 1. Only one toy can be assembled at a time on this line; then there is a changeover to the next toy. Currently, line 1 has 10 workers who engage in assembly, inspection, and packing of the toys. Some of the parts that are assembled into the finished toys are made on the company’s plastic-molding machines. Other parts are purchased from outside suppliers.

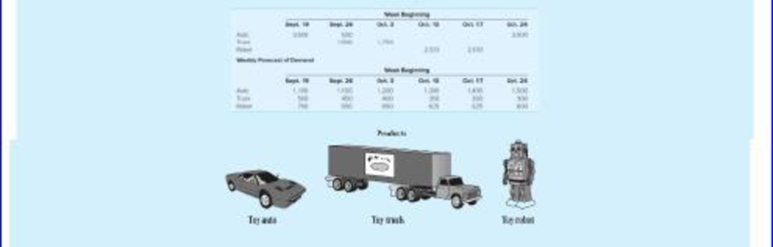

Production control is based on the MRP system. Every week a master

EXHIBIT 3 Master schedule prepared September 16, 2016.

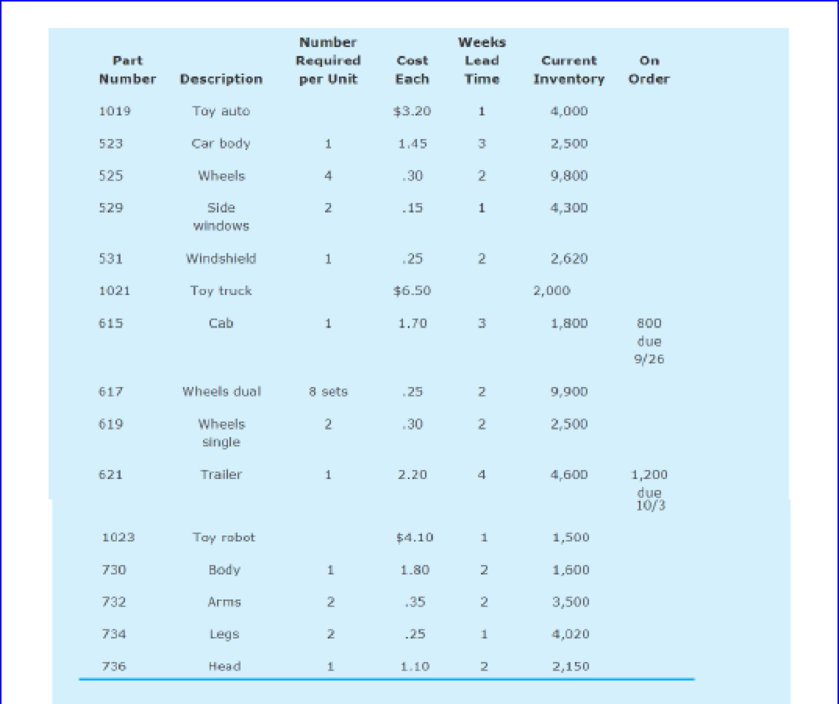

The computer performs a parts explosion using the bill of materials and the on- hand inventories shown in Exhibit 4. Each toy requires several parts, as indicated in the bill of materials. For example, each auto requires one body, four wheels, two side windows, and one windshield. These parts are assembled, the product is inspected, and the toy is packed, which requires a total of .1 labor hour per auto. With 10 people working on the assembly line, at present, there are 350 hours of productive time available per week (35 hours each times 10). If the entire week is used to make autos, a total of 3,500 autos can be produced (350/.1). It takes .2 hour to make a truck and .15 hour to make a robot, thereby making it possible to produce a maximum of 1,750 trucks or 2,333 robots, if the entire line is devoted to either of these products. Production, however, is scheduled in lots, and the entire week is not necessarily devoted to only one toy.

EXHIBIT 4 Bill of materials.

In between products it takes all 10 people one hour to change the setup of the line. This changeover involves moving out the parts for the old toy, moving in the parts for the new toy, arranging the jigs and fixtures for assembly, and making trial runs to make sure that quality is right. The shop labor rate is $14 per hour for wages, including

Purchasing does not always buy the exact number of parts that are ordered by the production control department. Adjustments are made to take advantage of price breaks from suppliers or to achieve full-truckload shipments. As a result, some additional parts might be purchased in order to reduce purchasing costs. Also, suppliers do not always ship the component parts when promised. As a result, ToysPlus carries safety stock inventory to protect the master production schedule and to keep the assembly lines running, no matter what. About one week of safety stock is carried to protect for late supplier deliveries. Management has mandated that the assembly lines will not shut down.

Dale Long has stated that the company will not lay off workers on a week-to- week basis. Thus, if demand should be less than capacity, for example, by 10 percent in a week, production will be scheduled to full capacity to keep the workers busy. If this condition should continue for several weeks, workers will be laid off to adjust capacity. In a similar way, workers will be put on overtime to meet demand temporarily. But if demand exceeds normal capacity for several weeks, more workers will then be added.

A six-week rolling production schedule, based on existing capacity and lead times, is used. Each week one more week is added to keep the total master schedule horizon at six weeks. Production is adjusted each week in line with available parts, capacity, and observed demand for toys.

HAPPY HOUR

Andrea walked to General Joe’s, a favorite watering hole, for happy hour with her friend from purchasing, John White. Andrea began,

John, I don’t know what I am going to do. Dale Long has laid the law down that I must reduce inventory and improve service levels. There is no alternative or excuses this time, I must do it! I’m not sure where to start. I would like better sales forecasts, but is that realistic to expect? Can I depend on marketing? I also could reduce inventory by achieving more reliable deliveries from our suppliers. Will they cooperate? Maybe we will have to react faster in laying off and hiring workers in order to keep capacity closer to demand. What do you think of this situation? Is there a solution?

John answered,

You must remember, Andrea, the world is filled with hustlers and liars. The salespeople lie to you about forecasts, so they can have more inventory, just in case they need it. We in purchasing lie to our suppliers about when we need the parts, so that we can be sure to get them when we really need them. You pad the production schedule a little bit, just to make sure you can meet the shipments. We all are trying to cover ourselves so that we don’t run out of stock. There isn’t a solution to this problem, because we are dealing with human nature. I hate to say it, but maybe top management’s expectations are a bit unrealistic that inventory should be reduced and service improved. How can they expect anyone to accomplish these goals in an environment like this?

Discussion Questions

- 1. Calculate economic order quantities for each of the three types of toys. The EOQ formula is recommended from the supplement to Chapter 14 that considers uniform lot delivery of the toys.

- 2. Prepare a master production schedule for the next six weeks using the EOQs calculated in question 1 and a workforce of 10 employees. What inventory turnover ratio is achieved by this master schedule? How does this turnover compare with past levels and with management’s goals?

- 3. Prepare a parts explosion to support the master schedule. What parts should be ordered each week? Are there enough planned orders in time to support your master schedule?

- 4. What should Andrea Meline do to meet the inventory and service goals stated by management? Hint: If the turnover is too low from your first analysis and is not feasible using available parts, try another master schedule that is feasible with reduced production levels, uses the available parts and has a turnover of 15.

- 5. How should Andrea deal with the organization issues presented in this case?

This case was prepared as a basis for class discussion, not to illustrate either effective or ineffective handling of an administrative situation.

Want to see the full answer?

Check out a sample textbook solution

Chapter CS Solutions

OPERATIONS MANAGEMENT IN THE SUPPLY CHAIN: DECISIONS & CASES (Mcgraw-hill Series Operations and Decision Sciences)

- For my learning and not a assignment question: Tesla, the U.S. electric vehicle manufacturer, has recently proposed to join Indonesia’s initiative to develop an EV battery supply chain within the country. This information was shared by a senior Indonesian government official, who noted that the government received Tesla's proposal on Thursday. Indonesia, known for its rich nickel reserves, is already in discussions with companies like China's Contemporary Amperex Technology (CATL) and South Korea's LG Chem to establish a comprehensive EV battery supply chain that covers everything from raw materials to the final product. Sepian Hari Seto, the deputy for investment and mining at the Coordinating Ministry of Maritime Affairs and Investment, expressed enthusiasm for Tesla's advanced lithium battery technology. He conveyed that the collaboration with Tesla, along with CATL and LG, presents a valuable opportunity for technology transfer and learning. Furthermore, Seto mentioned the…arrow_forwardYour company is considering investing in a Human Resource Information System (HRIS).Briefly explain the strategies for justifying HRIS investments.arrow_forwardPresent the criteria you would utilize to determine if a right should be extended to an employee or if it would unnecessarily impact a manager’s ability to manage. Additionally, assess how you would balance the need for management rights against the need for employee rights, and how greater employee rights positively and negatively affect the future of the organization.arrow_forward

- provide schoarly research and references as to how internal and exteral audit is a risk management strategy to mitigate risk in a financial institutionarrow_forwardLearning Activity 4: Strategic Sales Management How has the advent and rapid evolution of digital technology transformed traditional sales management strategies, and what do you think are the most significant challenges and opportunities this transformation brings? In addition, please select and describe an example of company that has embraced change and implemented a unique and effective sales strategy.arrow_forward1) View the two video excerpts (Ctrl+Click on the two links), Preview 1 to the Goal Movie (Goldratt) (11.17 minutes), https://www.youtube.com/watch?v=2RVMgV37O_k and Preview 2 to the Goal Movie – How to Version (Goldratt) (9.40 minutes) https://www.youtube.com/watch?v=t_oM9LvK0rU and answer the following questions: a) What problems is UniCo facing and how are they tackling these problems currently? b) What advice did Jonah give to Rogo, and what lessons did Rogo learn from “Herbie’s Hike”? c) How do you think Rogo can leverage Jonah’s advice (as well as the lessons learnt from “Herbie’s Hike”) to solve UniCo’s problems? 2) A business program has the facilities and faculty to handle an enrollment of 2,000 new students per semester. However, in an effort to limit class sizes to a “reasonable” level the business dean, placed a ceiling on enrollment of 1,500 new students. Although there was ample demand for business courses last semester, conflicting schedules allowed only 1,450 new…arrow_forward

- The global marketplace has undergone a dramatic transformation, demanding that businesses adapt their supply chain management and implement new strategies to ensure the reliable sourcing of materials and goods. Please choose an organisation that you are currently working for or you are familiar with where its procurement operations has been greatly affected. You may pick a commercial or public institution as a choice for your study. You will need to briefly describe the institution and explain its category management structure which support the strategic procurement. You are required to provide an overview and discuss how spend are identified along with the types of categories purchased Briefly describe the organisation that you have chosen. Analyse the criticality of both the category management and strategic sourcing that will impact the business needs of the institution that you have chosen. Laing oxemples from the institution you have selected appraise and recommend COarrow_forwardThe Ideal Spot in the Segment Circles So, where should you try to position your product in the segment circles? As a basic rule, the 'Ideal Spot' will help guide you. The ideal spot represents the position with the highest point of demand for each consumer base – or segment. The ideal spot is made up by the product’s performance (speed) and size. As the perceptual map drifts down and to the right each year, the ideal spot will change as customers demand sensors with decreased size (smaller) and increased performance (faster). Although it would seem that the Ideal Spot would be in the center of the segment circle, the positioning actually varies due to the customer focus of each segment. For example, in the High End segment, the Ideal Spot is at the leading edge of the segment because those customers want the best possible product. Each segment’s ideal spot is represented by the pink dots on the Perceptual Map. Ideal Spots offset from segment center Calculating the Ideal Spot To…arrow_forwardIn Ecuador, cut roses are one of the country’s leading exports. Prior to advancements in the air transportation industry, this would have been impossible as roses must be sold within three to five days once cut. Today Ecuador is one of the world’s top producers of roses.arrow_forward

- The World Trade Organization is the only global trade organization and has 164 member nations representing 98 percent of world trade. How does the WTO help nations improve trade relations? What are some of the major challenges facing the WTO today?arrow_forwardWhat is a good example of a letter of recommendation for a 5th grade Language Arts Teaching Position at an elementary school from a school principal?arrow_forwardProblem 1 (10 Points) Davison Electronics manufactures three LED television monitors, identified as Model A, Model B, and Model C. Davison Electronics four manufacturing plants. Each model has its lowest possible production cost when produced at Plant 1. However, Plant 1 does not have the capacity to handle the total production of all three models. As a result, at least some of the production must be routed to the other manufacturing plants. The following table shows the minimum production requirements for next month, the plant capacities in units per month, and the production cost per unit at each plant: Model Production Cost per Unit Minimum Production Requirements Plant 1 Plant 2 Plant 3 Plant 4 A $25 $28 $37 $34 48,000 B $26 $35 $36 $41 75,000 C $20 $31 $26 $23 60,000 Production Capacity 65,000 50,000 32,000 43,000 Davison’s objective is to determine the cost-minimizing production plan. We have…arrow_forward

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage LearningMarketingMarketingISBN:9780357033791Author:Pride, William MPublisher:South Western Educational Publishing

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage LearningMarketingMarketingISBN:9780357033791Author:Pride, William MPublisher:South Western Educational Publishing Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Contemporary MarketingMarketingISBN:9780357033777Author:Louis E. Boone, David L. KurtzPublisher:Cengage Learning

Contemporary MarketingMarketingISBN:9780357033777Author:Louis E. Boone, David L. KurtzPublisher:Cengage Learning