Concept explainers

Southern Toro Distributor, Inc.

The following conversation was held between Joe Melaney, general manager and owner of the Toro distributorship in Galveston, Texas, and his son Joe Jr.:

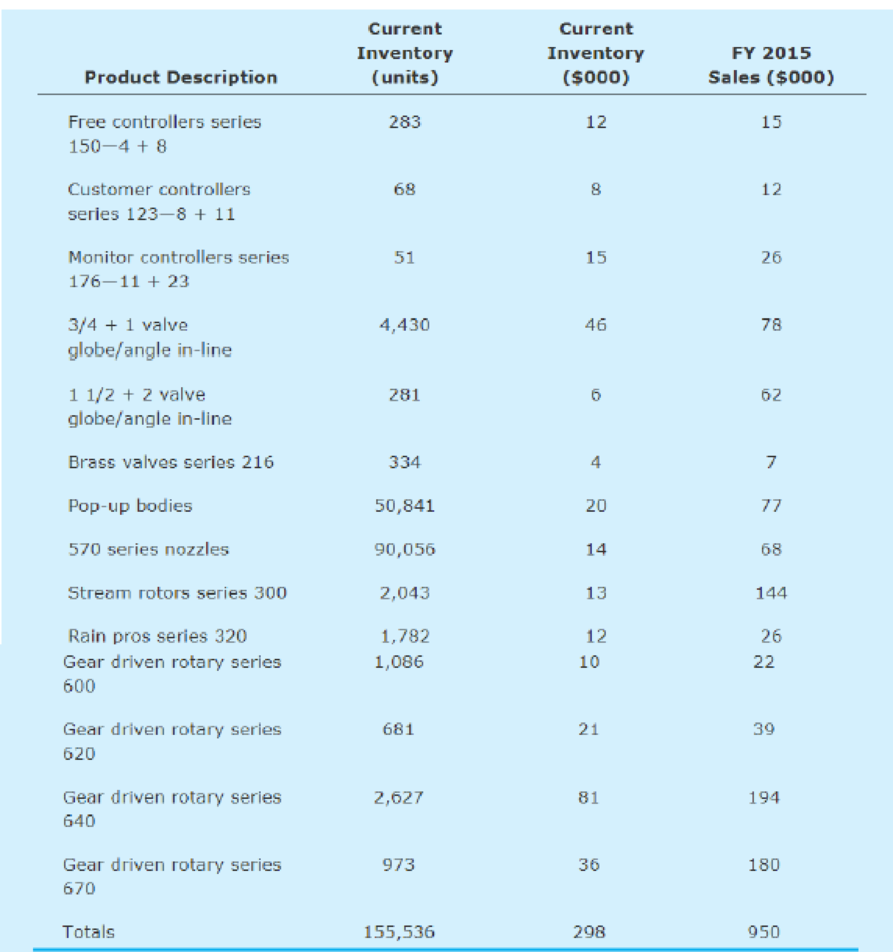

Joe: 1 called you in this morning to discuss the future of the company. I feel that you should be involved in more of the decision making around here because you will be taking over the company soon. Roger Kirk, the district sales manager from Toro, will be contacting us next week for our spring season order. We will need to order for the entire irrigation line at that time. (See Exhibit 1.)

EXHIBIT 1 Irrigation Products, Inc., current inventories, October 15, 2015.

Prepared for use in class discussion by Roger G. Schroeder, E.R. Kunde, and Sue Flach.

As you know, we have been undergoing a number of changes around the office. One of our major changes was acquiring the RyTech computer system. A computer run I received this morning combined with the upcoming order date started me thinking about the figures from the new computer. I was thinking back on the circumstances that led up to the purchase of the computer a year ago in October 2014. With the way costs are skyrocketing, I had to cut down on my inventory without cutting service. The RyTech representative said he could cut our inventory level by 30 percent, which sounded good enough for me. So I contracted with RyTech for the new software.

Max, our irrigation manager, swears by the numbers he gets out for order quantities. When this package was put into our computer, they (RyTech reps) said it was suitable for me, but I’m not sure that I can trust it. You remember the problems RyTech had getting it running. If they have problems like that, why should I trust it to tell me how to spend millions of my dollars?

Joe Jr: You mentioned that RyTech Installed the software for us. How did they select the decision rule used in determining the order quantities?

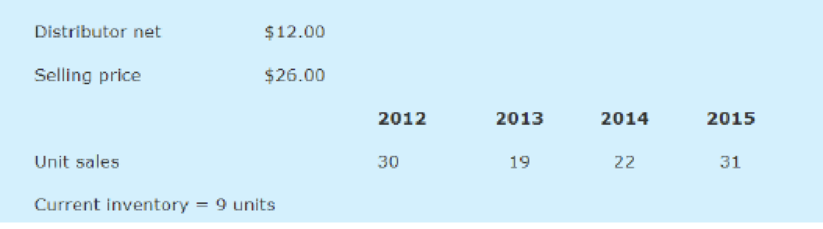

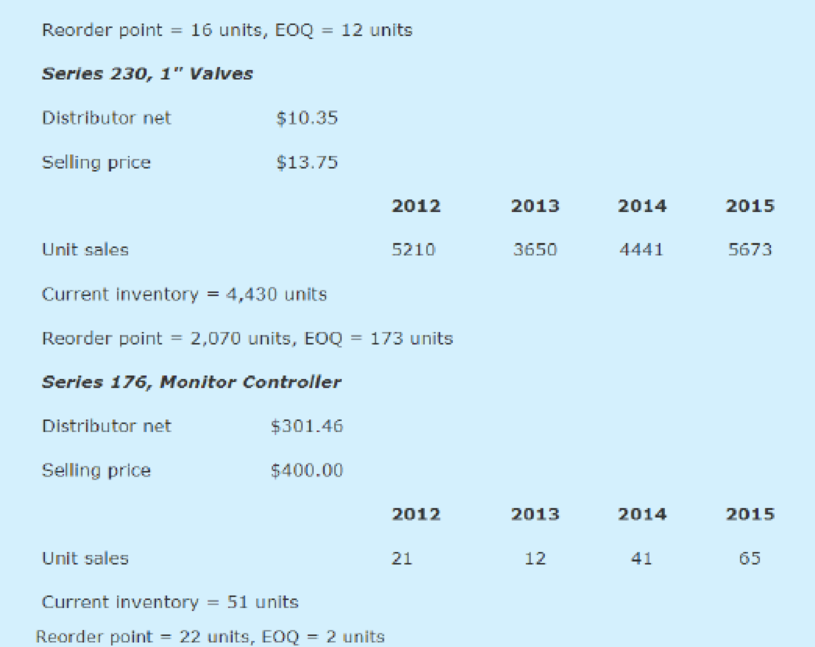

Joe; 1 can’t answer that. The consultants that came in told me the best way to determine the order quantities for my company was to use an economic order quantity (EOQ) and a reorder point for every item. (See Exhibit 2.) They said this was the best because we have three set order points during the year. I’m comfortable with the order point, but I’m not sure of the EOQ. I can tell you how the EOQ was made for us. They based it on the demand quantities from the past four years. (See Exhibit 3.) RyTech said that they did not see the need for any additional measures. They also said it would work very smoothly since it wasn’t necessary to change the EOQ once it was in.

EXHIBIT 2 Current computer system rules.

For order quantity size:*

A = cost of placing an order, $

D = annual demand in units

i = "interest rate" for holding inventory for a year as a proportion of the unit cost

c = unit cost of the item, $/unit

EOQ = economic order quantity

For reorder point:

R = average demand over the lead time + safety stock

R is the reorder point where an order for more stock is placed. Currently, a 12-week lead time is used for all items in setting the reorder point.

*The current computer system uses a carrying cost i = 30% (20% cost of capital, 5% obsolescence, and 5% storage cost) and an ordering cost of $10 per order.

EXHIBIT 3 Demand for fiscal years 2012-2015.

Part #1-7287 Timing Motor with Gear Service Assembly (for Monitor Controllers)

As I said earlier, I’m not sure of the EOQ. You know how I’ve depended upon my gut feel for the market in the past. I’ve always ordered parts based on past usage. Then I adjust the numbers according to how many golf courses I expect to be built or modified, and on the contractors’/installers’ comments on how they expect the spring to pane 464 go in terms of the number of installations. I also meet with friends in the building industry to see what they expect in terms of housing starts for the spring. My only other adjustments come if I think a particular product isn’t moving. I feel all goods should turn over at least three times a year. There are two items I am worried about at the present time because of that exact problem. One is the timing motor with gear service assembly (Part #1-7287), a low-volume service part carried for repair of monitor controllers, and the other is the Monitor Controller (Series 176) carried as an “insurance” end product for a few specialized customers. (See Exhibits 4 and 5 for detailed descriptions of the Monitor Controller and the Series 230 valve.)

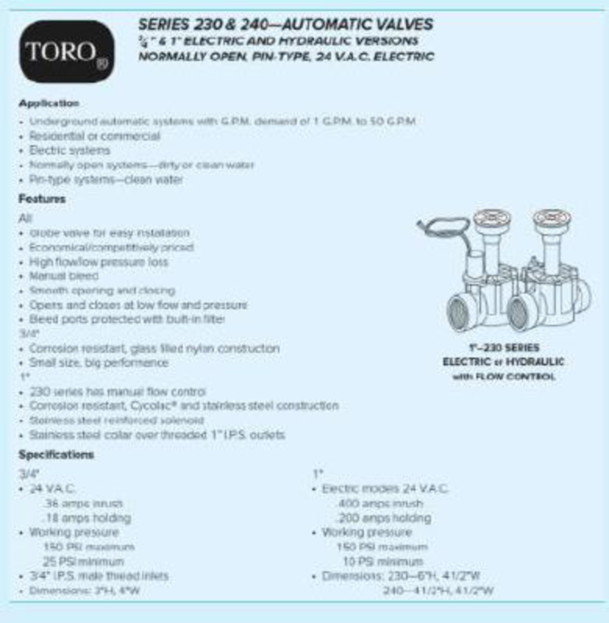

EXHIBIT 4 Series 230 and 240—Automatic valves. 3/4" & 1" electric and hydraulic versions normally open, pin-type, 24 V.A.C. electric.

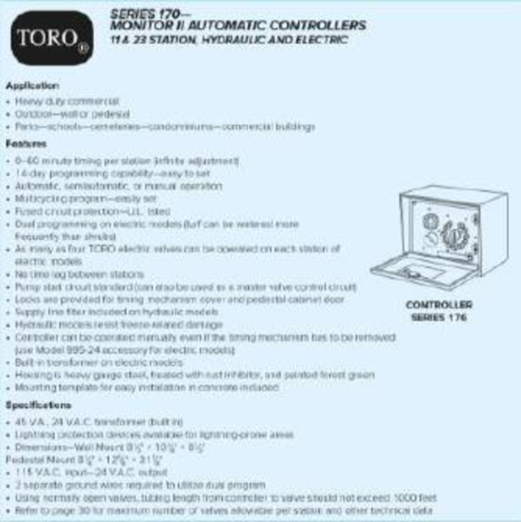

EXHIBIT 5 Series 170—Monitor II automatic controllers: 11 & 23 station, hydraulic and electric.

Joe Jr: I haven’t heard you mention the problem of running out of products. We have been having quite a problem with running out of the Series 230 1 inch valve, a high-demand part that we use all the time. How would you handle this in ordering? I know that we tend to disagree on what level of inventory should be held. I don’t think you are carrying a high enough inventory level on all parts to satisfy our customers. You have always said it is critical to the survival of the company that we have satisfied customers. I would tend to believe that this would require us to always have what our customers need on hand. The other problem I see resulting from stockouts is a loss of customers to our competitors. Any customer whose order we cannot fill will go to Rainbird, Weathermatic or Nelson. Any of these competitors could supply the customer with comparable equipment, and once the customers have made the change, how do we get them back?

Joe: I don’t have the storage capacity to carry enough inventory to protect ourselves from ever having a stockout. My philosophy has been that you can’t always satisfy the customer from on-hand inventory. But you better be able to satisfy them 90 percent of the time. When you don’t have it on hand, you can usually get it from another distributor. It usually is a fairly fast process because we fly the parts in. Too bad we can’t place rush orders with Toro, but they hold us to their standard ordering policy (Exhibit 6).

EXHIBIT 6 Irrigation division FY 2015-2016 stocking program, terms for southern distributors.

| Order Placement | Shipping Period | Dating Terms |

| 33% 2011 |

December and January | 1/2 May 15—net |

| Oct. 15-Oct. 30 | 1/2 June 15—net | |

| 33% 2012 Forecast | May and June | 1/2 Sept. 15—net |

| Feb. 15-Feb. 30 | 1/2 Oct. 15—net | |

| 33% 2012 Forecast | August and September | 1/2 Nov. 15-net |

| June 15-June 30 | 1/2 Dec. 15—net |

That reminds me, we have to face a possible stockout problem this year. When I was at the country club last week, George, the general manager at the club, was talking about the number of times their sprinkler system had failed. George mentioned that he had spoken to the board about replacing the system. While the board wouldn’t commit themselves until the annual meeting in December, George felt that it was going to be approved. If they installed the system, they wanted it ready to go by their annual tournament in early April. George said his first choice would be us if we could Page 467 supply the system within the time specified. This contract would be a highly profitable one. As you know, the course is 390 acres, and the entire system would have to be replaced. The replacement system would rely heavily on the use of the Series 230 valves.

Because of the size of the club’s system, I checked with my banker on the cost of financing. Bank notes were quoted at 9 percent. I’m not sure whether I should risk financing, so I’m looking at cutting back in the spare parts area, where a lot of our cash is tied up. I figured that we have 25 percent of our inventory just sitting in the warehouse collecting dust. Many of these items are used by only a few of our customers. If I decide against the latter technique, we would have to rent storage space to handle the parts for the golf course installation. When I checked into this yesterday, I was quoted a price of $3.27 per square foot per year for rented warehouse storage space.

To assist in determining the appropriate quantities and to get a little insight into the chance of the club’s installing the system, I called the National Weather Service this morning. They stated they expected the driest spring in five years. I’m not sure to what extent this would affect the sales of the irrigation products. To assist in determining the effect of weather on the sales, I have gone over the demand figures and the corresponding weather for the last five years. In 2012 and 2013 I greatly overstocked. During these years, the weather was extraordinarily wet and cloudy. During 2014 the reverse conditions existed. It was an abnormally dry season, and we stocked out of most of our goods. (See Exhibit 7 for more market characteristics.)

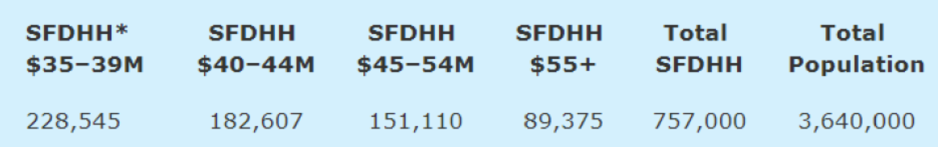

EXHIBIT 7 Galveston market information.

Number of golf courses: 158

Number of golf course holes: 2,259

Irrigation potential market (in purchases from Toro):†

| Small turf‡ | $403,830 | Number of cemeteries: 71 |

| Large turf‡ | 267,048 | Number of parks: 14 |

| Parts | 75,160 | Number of schools: 170 |

| Total | $846,038 |

*Number of persons living in single-family dwelling households (SFDHH).

† This is an estimate of the market size for Toro in the area.

‡ Small turf refers to residential installations while large turf refers to golf courses and other

commercial installations.

Joe Jr: With a business that is subject to the whims of nature, why do you stay in it? Is it really worth beating your head against the wall to get the kind of

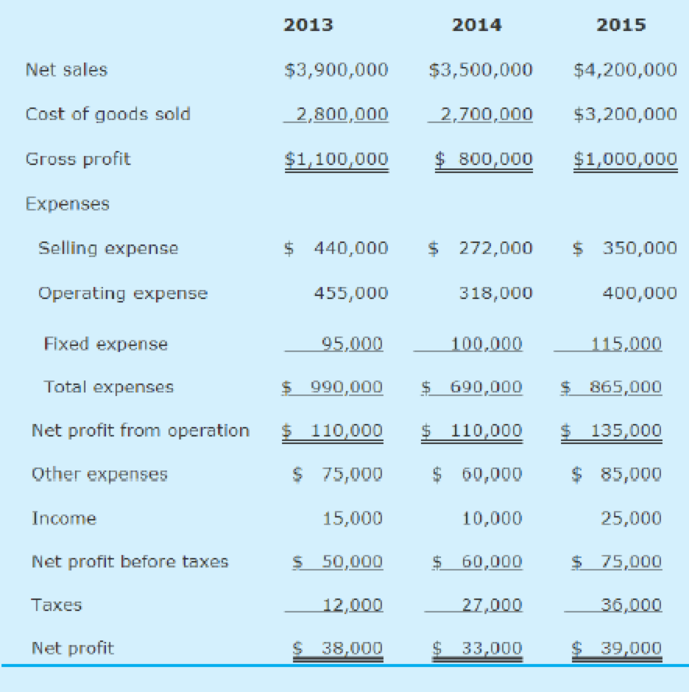

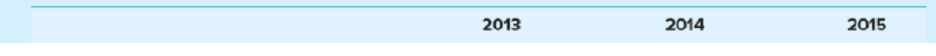

EXHIBIT 8 Income statement (fiscal years ending June 30).

EXHIBIT 9

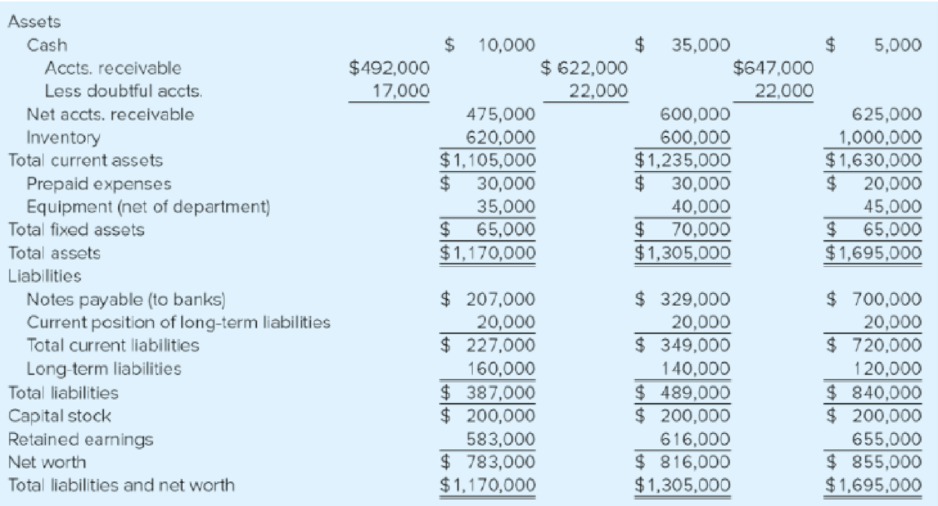

EXHIBIT 10 FY 2015 departmental analysis ($000).

Joe: In the past I stayed in this business because I started the business. It’s my baby. I felt a great deal of achievement from it. I’ve always planned to pass the company on to you and let you operate it. Now is the time for you to decide how you would run this company if you were in charge and if the return on investment is good enough for you to be satisfied. We also have to decide what to order from Roger Kirk when he arrives next week and what to do about using the RyTech system. I have another meeting now, but I would like to get back to this discussion later.

Discussion Questions

- 1. What would you recommend that Joe Jr. do, assuming he takes control of Southern Toro?

- 2. Evaluate the importance of inventory and inventory management of the Southern Toro distributorship for both irrigation products and spare parts. Should the inventory be cut back?

- 3. Evaluate the current inventory management system at Southern Toro. What inventory management system would you recommend?

Want to see the full answer?

Check out a sample textbook solution

Chapter CS Solutions

OPERATIONS MANAGEMENT IN THE SUPPLY CHAIN: DECISIONS & CASES (Mcgraw-hill Series Operations and Decision Sciences)

- How would you design and implement a modern networking solution for JAMS Manufacturing to connect all their facilities and ensure seamless communication? The company currently has standalone systems in three manufacturing plants and an office building, each using its own modem or router for internet access. The goal is to create private networks for each location, connect them to one another, and provide Internet access to all. You’ll need to consider factors like new computer systems, servers, and telecommunications wiring, and explain how your solution will benefit the company and how it will be implemented effectively.arrow_forwardIdentify specific performance management processes covered in this course and how each aligns with an elements of LaFevor’s HCMS Model.arrow_forwardIdentify specific performance management processes covered in this course and how each aligns with LaFevor’s HCMS Model. LaFevor, K. (2017). What’s in Your Human Capital Management Strategy? The Game Plan, the Path, and Achievingarrow_forward

- assess how Human Capital Management Strategy is aimed at building an effective integrated performance management system: Discuss how human capital management strategy relates to performance management.arrow_forwardCASE STUDY 9-1 Was Robert Eaton a Good Performance Management Leader? R obert Eaton was CEO and chairman of Chrys- ler from 1993 to 1998, replacing Lee Iacocca, who retired after serving in this capacity since 1978. Eaton then served as cochairman of the newly merged DaimlerChrysler organization from 1998 to 2000. In fact, Eaton was responsible for the sale of Chrysler Corporation to Daimler-Benz, thereby creating DaimlerChrysler. With 362,100 employees, DaimlerChrysler had achieved revenues of €136.4 billion in 2003. DaimlerChrysler's passenger car brands included Maybach, Mercedes-Benz, Chrysler, Jeep, Dodge, and Smart. Commercial vehicle brands included Mercedes-Benz, Freightliner, Sterling, Western Star, and Setra. From the beginning of his tenure as CEO, Eaton communicated with the people under him. He immediately shared his plans for the future with his top four executives, and upon the advice of his colleague, Bob Lutz, decided to look around the company before making any hasty…arrow_forwardCritically assess Martin’s coaching style.arrow_forward

- Compare Robert Eaton’s performance management leadership presented in the case against the performance management leadership principles, functions, and behaviors. What recommendations can be made about what he might do more effectively? Explain and defend your answer.arrow_forwardIn the context of the material in Chapter 9, provide a critical analysis of the decisions that Henry has made in assigning Martin to this role.arrow_forwardpanies (pp. 80-118). New York, NY: Times Books, specifically Chap. 4, "Robert Eaton and Robert Lutz; The Copilots." CASE STUDY 9-2 Performance Management Leadership at Henry's Commercial Sales and Leasing H enry is the owner of a small real estate agency that handles the sale and leasing of commercial property. He has two real estate agents working in the office, along with himself. He also has two customer service representatives (CSRs), each of whom has a real estate license, and one receptionist who has worked for the company for about three months. Henry has recently decided that he needs another customer service representative. He hasarrow_forward

- Discuss possible solutions to help Tara become an effective CSR. What should martin be doing to help her?arrow_forwardWhat are the ethical challenges regarding employees (i.e., diversity, discrimination, sexual harassment, privacy, employee theft, bad leadership, etc.) that Apple Inc. has faced over the past five to ten years and that they should prepare to face in the next five to ten years. Once a developed list of challenges is created, consider how having faced those challenges will impact and be impacted by the social cause you've selected. Propose the findings on the ethical challenges faced by Apple Inc. in recent history and the near future. Analyze ways in which each challenge was (and/or could be) appropriately handled and areas for improvement. Evaluate the ethical/moral aspects of Apple Inc. that protected it from ethical challenges in the past and could protect it in the future. Assess how ethical challenges and handling of ethical challenges could positively or negatively impact the charitable cause are selected and how the selection of your social cause could positively or negatively…arrow_forwardBy selecting Cigna Accredo pharmacy that i identify in my resand compare the current feedback system against the “Characteristics of a Good Multiple Source Feedback Systems” described in section 8-3-3. What can be improved? As a consultant, what recommendations would you make?arrow_forward

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,- MarketingMarketingISBN:9780357033791Author:Pride, William MPublisher:South Western Educational Publishing