Consolidated Electric: Inventory Control

Joe Henry, the sole owner and president of the Consolidated Electric Company, reflected on his inventory management problems. He was a major wholesale supplier of equipment and supplies to electrical contractors, and his business hinged on the efficient management of inventories to meet his customers' needs. While Henry had built a very successful business, he was nearing retirement age and wanted to pass along a good inventory management system.

Henry's two sons-in-law were employed in the company. Carl Byerly, the older of the two, had a college degree in mathematics and was very interested in Inventory formulas and computers. The other son-in-law, Edward Wright, had a degree in biology and was manager of one of the company’s wholesale warehouses.

Joe Henry started the Consolidated Electric Company in the 1940s and built it Into a highly profitable business. In 2016 the company had achieved S10 million in sales and earned SI million in pretax profits. Consolidated Electric was currently the twelfth largest electrical wholesaler in the country.

Consolidated Electric operates through four warehouses in Iowa (Des Moines, Cedar Rapids, Sioux City, and Davenport). From these sites, contractors in Iowa, Minnesota, Nebraska, Wisconsin, Illinois, and Missouri are supplied with a wide range of electrical equipment, including wire, electrical boxes, connectors, lighting fixtures, and electrical controllers. The company stocks 20,000 separate line items In Its Inventory purchased from 200 different manufacturers. (A line Item is defined as a particular item carried at a particular location.) These items range from less than 1 cent each to several hundred dollars for the largest electrical controllers.

Of the 20,000 line items, a great many are carried to provide a full line of service. For example, the top 2,000 items account for 50 percent of the sales and the bottom 10,000 items for only 20 percent. The remaining 8,000 items account for 30 percent of the sales.

The company has continually purged its 20,000 inventory items to carry only those that are demanded at least once a year. As Henry says, “We live and die by good customer service at a reasonable selling price. If we do not meet this objective, the customer will go to another wholesaler or buy directly from the manufacturer.”

Henry explained that he currently managed inventory by using an "earn and turn" concept. According to this concept, the earnings margin multiplied by the inventory turn ratio must equal a constant value of 2.0. For example, if a particular electrical item costs $6 to purchase wholesale and is sold for $10, then the earnings margin is $4 and the earn ratio for this item is $4/$10 = .40. If this item has a turn ratio of 5 times a year (sales are 5 times the average inventory carried), then the product of earn and turn is .4(5) = 2.0. If another item earns more, it can turn slower; if it earns less, it must turn faster.

Each year, Henry sets a target earn-tum ratio for the entire business and a value for each product line. These targets are based on the estimated costs of operations and the return-on-investment goal for the company. As stated above, the current target ratio for the business is 2.0. The purchasing agents and inventory managers at each location are measured by their ability to meet the target earn-turn ratios on their product lines. The actual ratios are reported monthly.

Although earn-turn ratios work quite well in controlling profitability of the business and entire product lines, they do not work very well for individual inventory items. Some line items tend to be in excess supply, while others are often out of stock.

The inventory is currently managed by use of a small computer system. A record for each item is kept and a clerk posts transactions on the record as units are received or issued, thus keeping a running on-hand inventory balance. Periodically, a purchasing agent reviews the records for a particular supplier. Then, using the order point and quantity stored on the record, the purchasing agent places an order for all items that are below their reorder point.

If the total quantities of all items required from a supplier do not meet the purchase discount minimums or a truckload lot, additional items near their reorder points are added to the order. This is not done when the total order size is too far from the minimums, since excessive Inventories would build up.

The order quantity and reorder point on each record are based on judgment and past experience. Generally speaking, a three-month supply is ordered for low-cost items and as little as a one-month supply for expensive items. Most lines are reviewed on a weekly basis.

Consolidated Electric had been converting its inventory records to a new software system. At the present time, an on-hand balance is maintained on the computer, and an accurate history of all orders placed, receipts, and issues is kept.

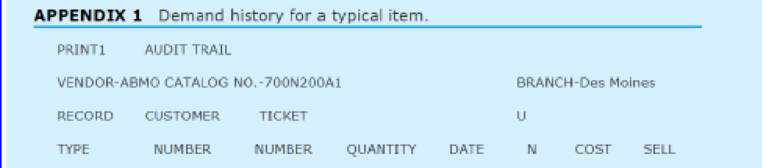

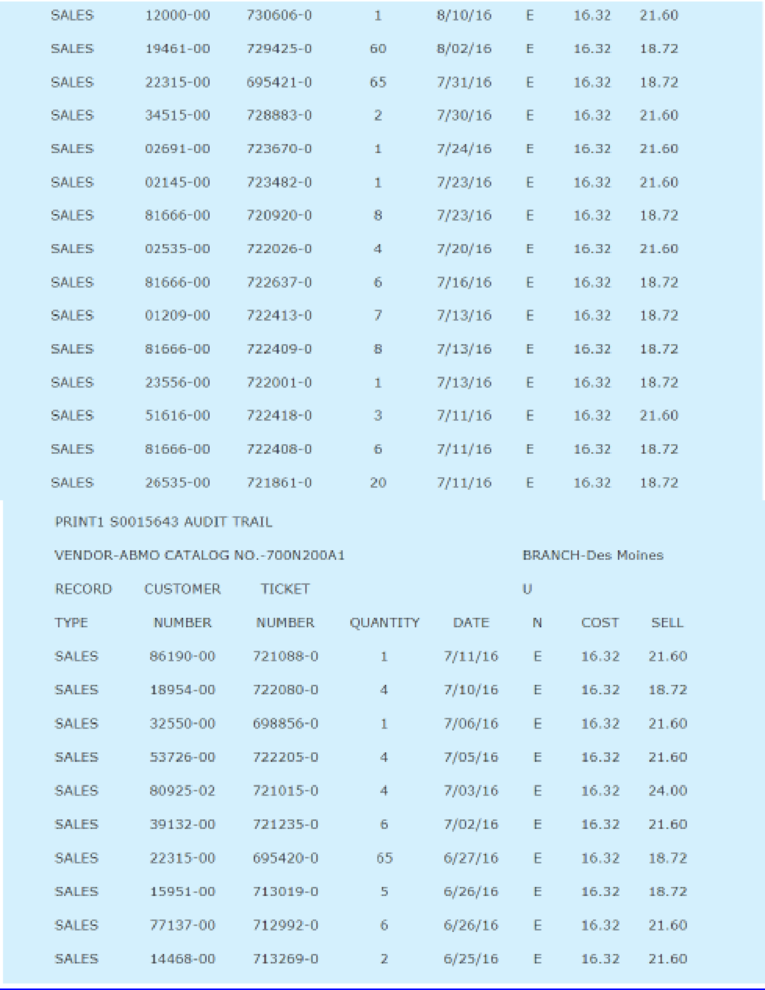

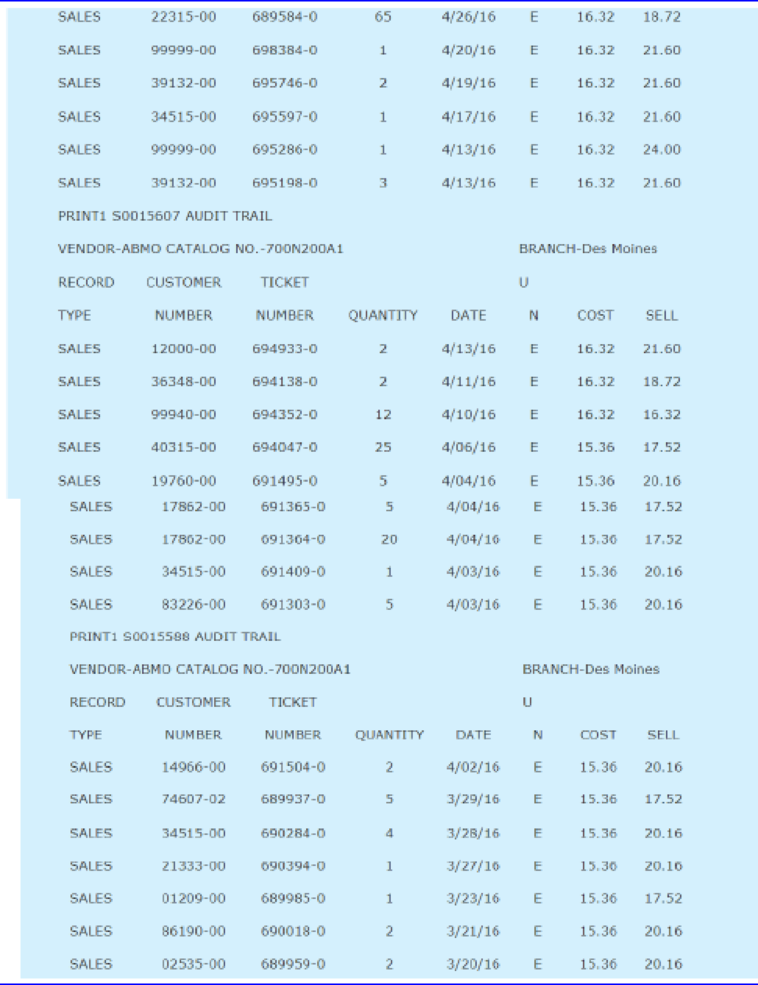

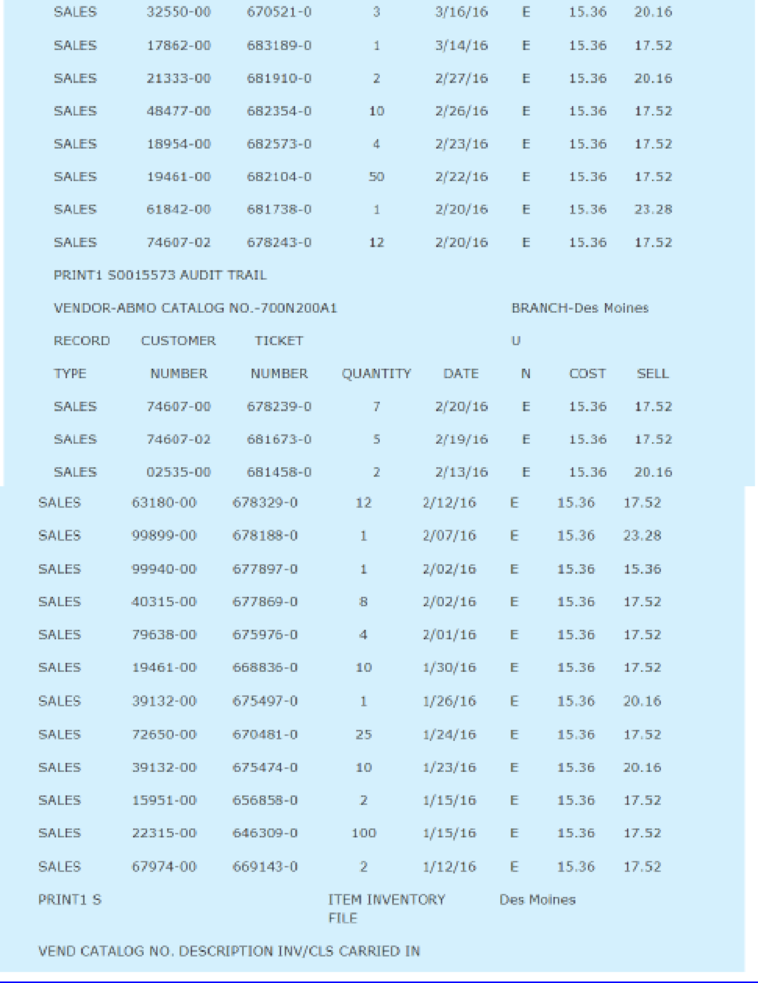

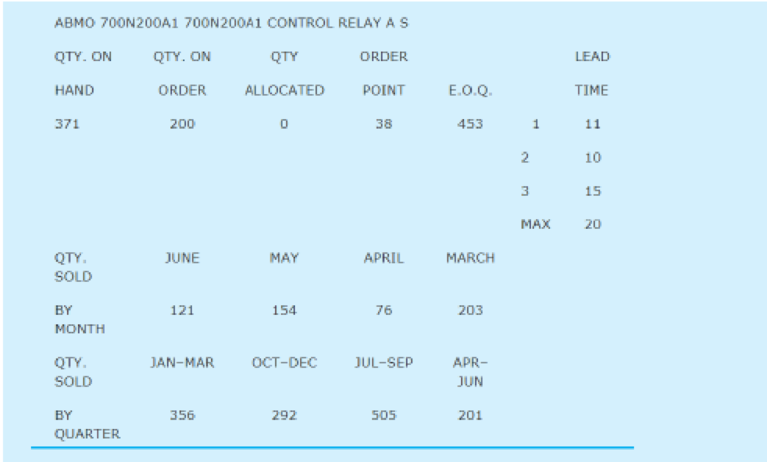

A demand history for a typical item is shown in Appendix 1.

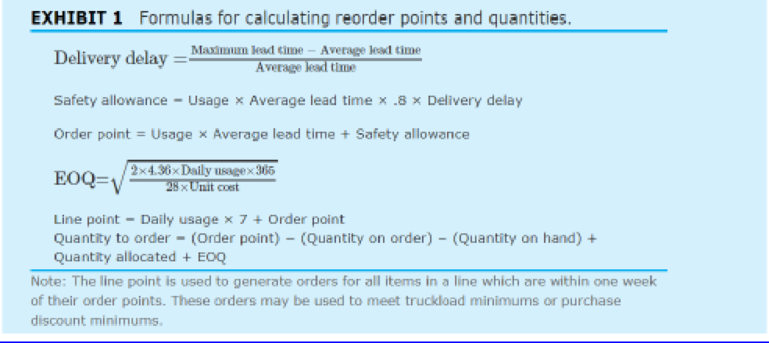

Henry was anxious to utilize the new system to calculate reorder points and order quantities, but he was unsure of the exact formulas to use. Using standard textbooks in the inventory field, Henry and Carl Byerly developed the formulas given in Exhibit 1. The EOQ formula utilizes a carrying cost of 28 percent and an ordering cost of $4.36 per order placed. These figures were based on past cost history at the company.

The formulas were programmed into the computer and tested on a pilot basis. For some Items the formulas seemed to work quite well, but for others they resulted in drastic departures from current practice and from common sense. For example, on one electrical box, the formulas would have ordered a two-year supply. Henry wanted to get the new software up as soon as possible, but he was not sure that the formulas would work properly. He wondered whether the formulas would meet the customer-service objectives of the business. Would they take advantage of truckload lots or purchase discounts whenever appropnate, and would the formulas result in reasonable inventory levels?

Discussion Questions

1. Design an inventory

2. Describe how the system you have designed will help the company meet customer-service and cost obiectives.

This case was prepared as a basis for class discussion, not to illustrate either effective or ineffective handling of an administrative situation.

Want to see the full answer?

Check out a sample textbook solution

Chapter CS Solutions

OPERATIONS MANAGEMENT IN THE SUPPLY CHAIN: DECISIONS & CASES (Mcgraw-hill Series Operations and Decision Sciences)

- How would you design and implement a modern networking solution for JAMS Manufacturing to connect all their facilities and ensure seamless communication? The company currently has standalone systems in three manufacturing plants and an office building, each using its own modem or router for internet access. The goal is to create private networks for each location, connect them to one another, and provide Internet access to all. You’ll need to consider factors like new computer systems, servers, and telecommunications wiring, and explain how your solution will benefit the company and how it will be implemented effectively.arrow_forwardIdentify specific performance management processes covered in this course and how each aligns with an elements of LaFevor’s HCMS Model.arrow_forwardIdentify specific performance management processes covered in this course and how each aligns with LaFevor’s HCMS Model. LaFevor, K. (2017). What’s in Your Human Capital Management Strategy? The Game Plan, the Path, and Achievingarrow_forward

- assess how Human Capital Management Strategy is aimed at building an effective integrated performance management system: Discuss how human capital management strategy relates to performance management.arrow_forwardCASE STUDY 9-1 Was Robert Eaton a Good Performance Management Leader? R obert Eaton was CEO and chairman of Chrys- ler from 1993 to 1998, replacing Lee Iacocca, who retired after serving in this capacity since 1978. Eaton then served as cochairman of the newly merged DaimlerChrysler organization from 1998 to 2000. In fact, Eaton was responsible for the sale of Chrysler Corporation to Daimler-Benz, thereby creating DaimlerChrysler. With 362,100 employees, DaimlerChrysler had achieved revenues of €136.4 billion in 2003. DaimlerChrysler's passenger car brands included Maybach, Mercedes-Benz, Chrysler, Jeep, Dodge, and Smart. Commercial vehicle brands included Mercedes-Benz, Freightliner, Sterling, Western Star, and Setra. From the beginning of his tenure as CEO, Eaton communicated with the people under him. He immediately shared his plans for the future with his top four executives, and upon the advice of his colleague, Bob Lutz, decided to look around the company before making any hasty…arrow_forwardCritically assess Martin’s coaching style.arrow_forward

- Compare Robert Eaton’s performance management leadership presented in the case against the performance management leadership principles, functions, and behaviors. What recommendations can be made about what he might do more effectively? Explain and defend your answer.arrow_forwardIn the context of the material in Chapter 9, provide a critical analysis of the decisions that Henry has made in assigning Martin to this role.arrow_forwardpanies (pp. 80-118). New York, NY: Times Books, specifically Chap. 4, "Robert Eaton and Robert Lutz; The Copilots." CASE STUDY 9-2 Performance Management Leadership at Henry's Commercial Sales and Leasing H enry is the owner of a small real estate agency that handles the sale and leasing of commercial property. He has two real estate agents working in the office, along with himself. He also has two customer service representatives (CSRs), each of whom has a real estate license, and one receptionist who has worked for the company for about three months. Henry has recently decided that he needs another customer service representative. He hasarrow_forward

- Discuss possible solutions to help Tara become an effective CSR. What should martin be doing to help her?arrow_forwardWhat are the ethical challenges regarding employees (i.e., diversity, discrimination, sexual harassment, privacy, employee theft, bad leadership, etc.) that Apple Inc. has faced over the past five to ten years and that they should prepare to face in the next five to ten years. Once a developed list of challenges is created, consider how having faced those challenges will impact and be impacted by the social cause you've selected. Propose the findings on the ethical challenges faced by Apple Inc. in recent history and the near future. Analyze ways in which each challenge was (and/or could be) appropriately handled and areas for improvement. Evaluate the ethical/moral aspects of Apple Inc. that protected it from ethical challenges in the past and could protect it in the future. Assess how ethical challenges and handling of ethical challenges could positively or negatively impact the charitable cause are selected and how the selection of your social cause could positively or negatively…arrow_forwardBy selecting Cigna Accredo pharmacy that i identify in my resand compare the current feedback system against the “Characteristics of a Good Multiple Source Feedback Systems” described in section 8-3-3. What can be improved? As a consultant, what recommendations would you make?arrow_forward

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Foundations of Business (MindTap Course List)MarketingISBN:9781337386920Author:William M. Pride, Robert J. Hughes, Jack R. KapoorPublisher:Cengage Learning

Foundations of Business (MindTap Course List)MarketingISBN:9781337386920Author:William M. Pride, Robert J. Hughes, Jack R. KapoorPublisher:Cengage Learning Foundations of Business - Standalone book (MindTa...MarketingISBN:9781285193946Author:William M. Pride, Robert J. Hughes, Jack R. KapoorPublisher:Cengage Learning

Foundations of Business - Standalone book (MindTa...MarketingISBN:9781285193946Author:William M. Pride, Robert J. Hughes, Jack R. KapoorPublisher:Cengage Learning