Concept explainers

6-51* to 6-53* For the problem specified in the table, build upon the results of the original problem to deter-mine the minimum factor of safety for fatigue at point A, based on infinite life, using the modified Goodman criterion. If the life is not infinite, estimate the number of cycles. The force F is applied as a repeated load. The material is AISI 1018 CD steel.

| Problem Number | Original Problem, Page Number |

| 6-53* | 3-86, 155 |

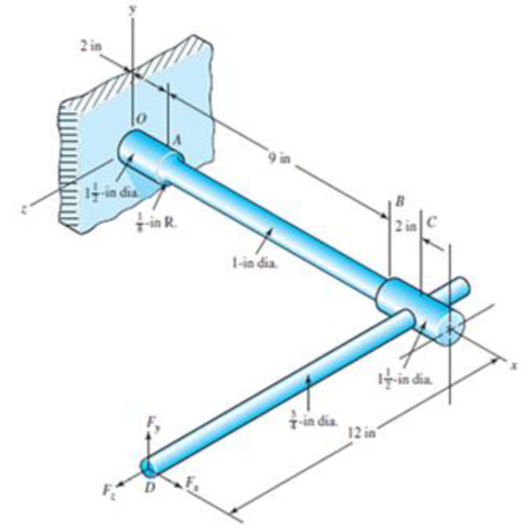

3-86* Repeat Prob. 3-84 with Fx = 300 Ibf, Fy = 250 Ibf. and Fz = −100 Ibf.

3-84* The cantilevered bar in the figure is made from a ductile material and is statically loaded with Fy = 250 Ibf and Fx = Fz = 0. Analyze the stress situation in the small diameter at the shoulder at A by obtaining the following information.

- (a) Determine the precise location of the critical stress element at the cross section at A.

- (b) Sketch the critical stress clement and determine magnitudes and directions for all stresses acting on it. (Transverse shear may be neglected if you can justify this decision.)

- (c) For the critical stress clement, determine the principal stresses and the maximum shear stress.

Want to see the full answer?

Check out a sample textbook solution

Chapter 6 Solutions

Shigley's Mechanical Engineering Design (McGraw-Hill Series in Mechanical Engineering)

- Q1/ A vertical, circular gate with water on one side as shown. Determine the total resultant force acting on the gate and the location of the center of pressure, use water specific weight 9.81 kN/m³ 1 m 4 marrow_forwardI need handwritten solution with sketches for eacharrow_forwardGiven answers to be: i) 14.65 kN; 6.16 kN; 8.46 kN ii) 8.63 kN; 9.88 kN iii) Bearing 6315 for B1 & B2, or Bearing 6215 for B1arrow_forward

- (b) A steel 'hot rolled structural hollow section' column of length 5.75 m, has the cross-section shown in Figure Q.5(b) and supports a load of 750 kN. During service, it is subjected to axial compression loading where one end of the column is effectively restrained in position and direction (fixed) and the other is effectively held in position but not in direction (pinned). i) Given that the steel has a design strength of 275 MN/m², determine the load factor for the structural member based upon the BS5950 design approach using Datasheet Q.5(b). [11] ii) Determine the axial load that can be supported by the column using the Rankine-Gordon formula, given that the yield strength of the material is 280 MN/m² and the constant *a* is 1/30000. [6] 300 600 2-300 mm wide x 5 mm thick plates. Figure Q.5(b) L=5.75m Pinned Fixedarrow_forwardHelp ارجو مساعدتي في حل هذا السؤالarrow_forwardHelp ارجو مساعدتي في حل هذا السؤالarrow_forward

- Q2: For the following figure, find the reactions of the system. The specific weight of the plate is 500 lb/ft³arrow_forwardQ1: For the following force system, find the moments with respect to axes x, y, and zarrow_forwardQ10) Body A weighs 600 lb contact with smooth surfaces at D and E. Determine the tension in the cord and the forces acting on C on member BD, also calculate the reaction at B and F. Cable 6' 3' wwwarrow_forward

- Help ارجو مساعدتي في حل هذا السؤالarrow_forwardQ3: Find the resultant of the force system.arrow_forwardQuestion 1 A three-blade propeller of a diameter of 2 m has an activity factor AF of 200 and its ratio of static thrust coefficient to static torque coefficient is 10. The propeller's integrated lift coefficient is 0.3.arrow_forward

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning