Concept explainers

a)

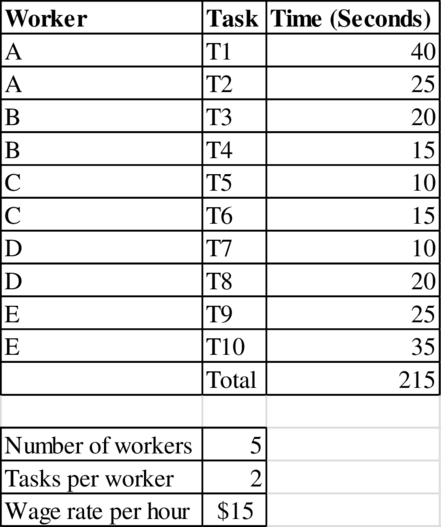

To determine: The labor content.

a)

Explanation of Solution

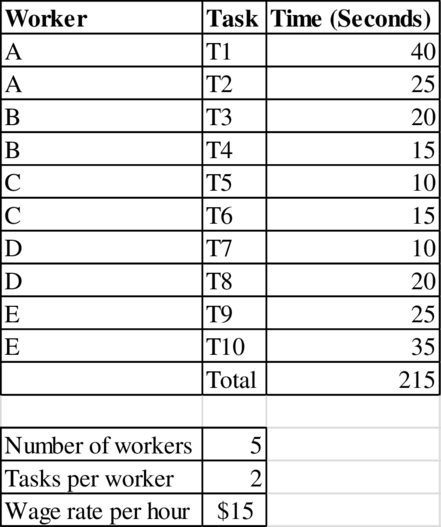

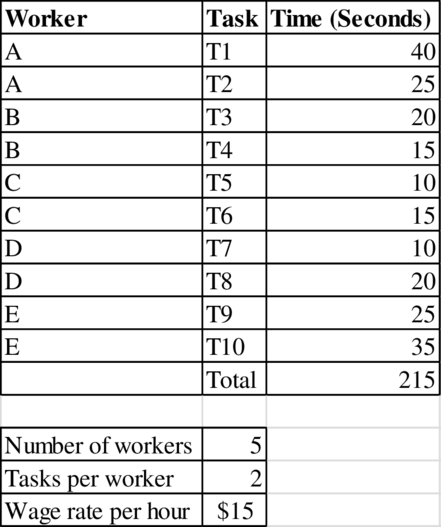

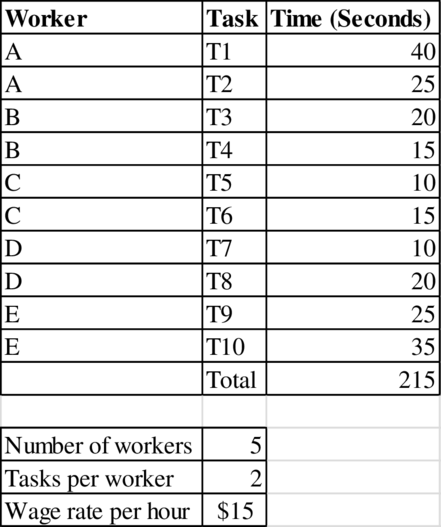

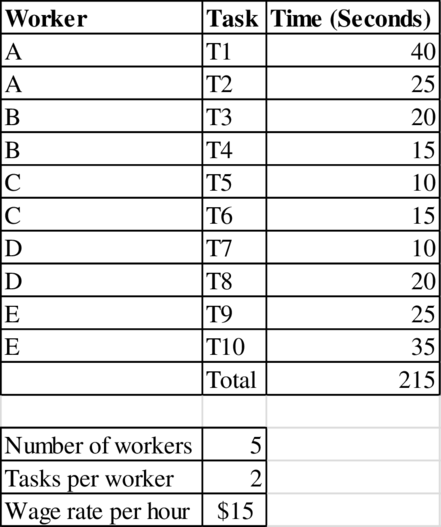

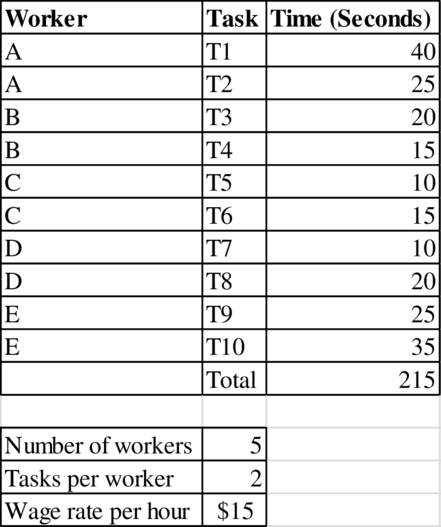

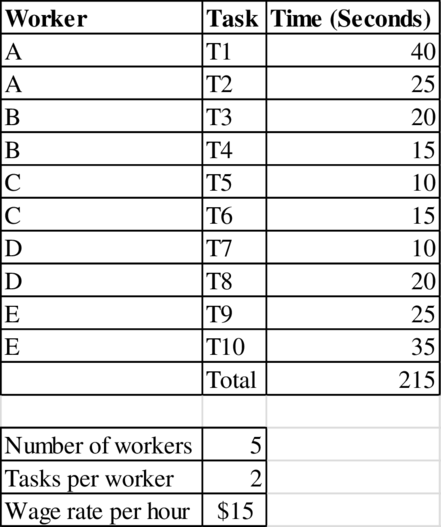

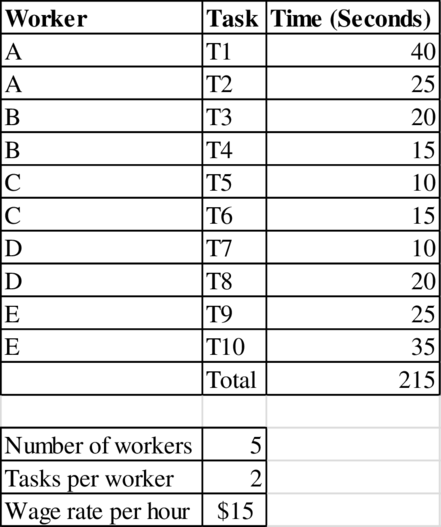

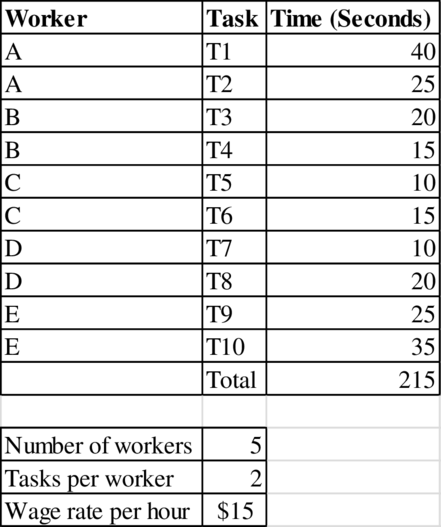

Given information:

Labor content:

The labor content is total time required to perform all the tasks of by the workers. It is 215 seconds.

The labor content is 215 seconds.

b)

To determine: The cost of direct labor for a toothbrush.

b)

Explanation of Solution

Given information:

Calculation of time per worker:

The time for Worker A is 65 seconds.

The time for Worker B is 35 seconds.

The time for Worker C is 25 seconds.

The time for Worker D is 30 seconds.

The time for Worker E is 60 seconds.

The bottleneck is Worker A with 65 seconds. Therefore, the flow rate will be:

Cost of direct labor:

The cost of direct labor per toothbrush is $1.35.

c)

To determine: The utilization of worker A.

c)

Explanation of Solution

Given information:

Utilization of Worker A:

The time for Worker A is 65 seconds. It is the bottleneck time of the entire process. Therefore, the utilization is 100%.

The utilization of 100%.

d)

To determine: The average labor utilization of the process.

d)

Explanation of Solution

Given information:

Average labor utilization of the process:

The cycle time will be equal to the bottleneck time which is 65 seconds. The average labor utilization will be:

The average labor utilization of 66.15%.

e)

To determine: The Takt time.

e)

Explanation of Solution

Given information:

Demand rate = 40 toothbrushes per hour

Takt time:

The Takt time is 90 second per toothbrush.

f)

To determine: The target manpower.

f)

Explanation of Solution

Given information:

Takt time = 50 seconds

Target manpower

The target manpower is 4.3 workers.

g)

To determine: The capacity of the process after hiring the new worker.

g)

Explanation of Solution

Given information:

New capacity of the process:

The new worker is added to Task 1 and Task 2 as it is the bottleneck of the process. After the addition of the new worker, the bottleneck is Worker E with a total time of 60 seconds. Therefore, the new capacity will be:

The capacity of process is 60 toothbrushes per hour.

h)

To determine: The capacity of the process.

h)

Explanation of Solution

Given information:

New capacity of the process:

The tasks are assigned to minimize the maximum work across the various workers. Task 1 is assigned to Worker A. Tasks 2, 3 is assigned to Worker B. Tasks 4, 5, 6, and 7 is assigned to Worker C. Tasks 8, 9 is assigned to Worker D. Task 10 is assigned to Worker E. The bottleneck time now is Worker 3 with 50 seconds. Therefore, the capacity is:

The capacity of process is 60 toothbrushes per hour.

i)

To determine: The capacity of the process with the new method

i)

Explanation of Solution

Given information:

New capacity of the process:

The capacity of process is 83.7 toothbrushes per hour.

Want to see more full solutions like this?

Chapter 4 Solutions

OPERATIONS MANAGEMENT

- Examine the conflicts between improving customer service levels and controlling costs in sales. Strategies to Balance Both customer service levels and controlling costs in sales 1.Outsourcing and workforce optimization 2. AI-driven customer supportarrow_forwardhow can you gain trust in a negotiation setting?arrow_forward✓ Custom $€ .0 .on File Home Insert Share Page Layout Formulas Data Review View Help Draw Arial 10 B B14 ✓ X✓ fx 1400 > 甘く 曲 > 冠 > Comments Editing ✓ . . . P Q R S T 3 A Production cost ($/unit) B с D E F G H J K L M N $74.00 4 Inventory holding cost ($/unit) $1.50 5 Lost sales cost ($/unit) $82.00 6 Overtime cost ($/unit) $6.80 7 Undertime cost ($/unit) $3.20 8 Rate change cost ($/unit) $5.00 9 Normal production rate (units) 2,000 10 Ending inventory (previous Dec.) 800 11 Cumulative 12 13 Month Demand Cumulative Demand Product Production Availability Ending Inventory Lost Cumulative Cumulative Product Sales 14 January 1,400 1,475 15 FUERANZ222222223323333BRUINE 14 February 1,000 2,275 Month January February Demand Demand Production Availability Ending Inventory Lost Sales 1,400 #N/A 1,475 #N/A #N/A #N/A 1,000 #N/A 2,275 #N/A #N/A #N/A 16 March 1,800 2,275 March 1,800 #N/A 2,275 #N/A #N/A #N/A 17 April 2,700 2,275 April 2,700 #N/A 2,275 #N/A #N/A #N/A 18 May 3,000 2,275 May 3,000 #N/A…arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Understanding Management (MindTap Course List)ManagementISBN:9781305502215Author:Richard L. Daft, Dorothy MarcicPublisher:Cengage Learning

Understanding Management (MindTap Course List)ManagementISBN:9781305502215Author:Richard L. Daft, Dorothy MarcicPublisher:Cengage Learning Management, Loose-Leaf VersionManagementISBN:9781305969308Author:Richard L. DaftPublisher:South-Western College Pub

Management, Loose-Leaf VersionManagementISBN:9781305969308Author:Richard L. DaftPublisher:South-Western College Pub