Concept explainers

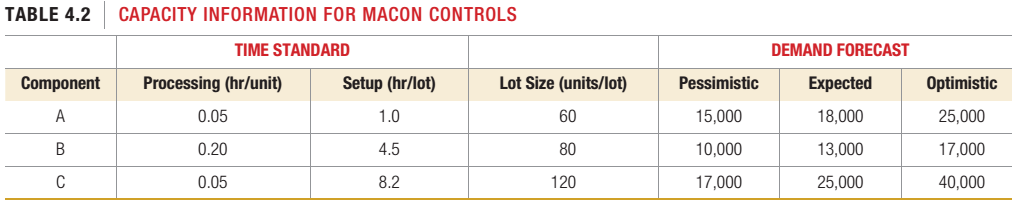

Macon Controls produces three different types of control units used to protect industrial equipment from overheating. Each of these Linus must be processed by a machine that Macon considers to be their process bottle neck. The plant operates on two 8-hour shifts, 5 days per week, 52 weeks per year. Table 4.2 provides the time standards at the bottleneck, lot sizes, and demand

- How many machines are required to meet minimum (pessimistic) demand, expected demand, and maximum (optimistic) demand?

- How many machines are required if the operations manager decides to double lot sizes?

- If the operations manager has three machines and believes that the plant can reduce setup time by 20 percent through process improvement initiatives, does that plant have adequate capacity to meet all demand scenarios without increasing lot sizes?

Want to see the full answer?

Check out a sample textbook solution

Chapter 4 Solutions

Operations Management: Processes and Supply Chains, Student Value Edition Plus MyLab Operations Management with Pearson eText -- Access Card Package (11th Edition)

Additional Business Textbook Solutions

OPERATIONS MANAGEMENT IN THE SUPPLY CHAIN: DECISIONS & CASES (Mcgraw-hill Series Operations and Decision Sciences)

Principles Of Operations Management

Operations and Supply Chain Management 9th edition

Operations Management

Operations Management

Principles of Operations Management: Sustainability and Supply Chain Management (10th Edition)

- Panini, a popular sandwich shop, offers 3 types of sandwiches: grilled vegetables, grilled chicken, and pastrami. The table below provides demand data: Grilled Vegetables Grilled Chicken Pastrami Demand per hour 25 9 12 There are up to five steps in the process of making sandwiches listed below with activity times (if no activity time, then than step is not done for that sandwich). Only 50% of customers want their sandwich toasted, no matter which sandwich is ordered. Step Grilled Vegetables(in minutes) Grilled Chicken(in minutes) Pastrami(in minutes) Cut bread 1 1 1 Grill 1.2 1.2 Slice meat 2 Toast 1.2 1.2 1.2 Wrap 0.8 0.8 0.8 Suppose Panini employs 1 worker at each step. a) Does Panini have enough capacity to fulfill the current demand for sandwiches? (b) What is the current capacity cushion for Panini? (as a %) c) If demand for Pastramis increase with the percentage indicated below, how much additional workers should Panini hire (if any), and where…arrow_forwardManufacturing Company uses FIFO method of accumulating costs in a two-department process. Materials are introduced at the inception of the process except for a special material which is added in department 2 at 60% completion as to overhead. Inspection is done at the end of the process in both departments. Production data for Department 2 are given below: In process, beginning, (80% labor, 70% overhead)2,000 Transferred in 14,900 In process, ending (40% labor, 20% overhead) 3,000 Normal spoilage 200 Abnormal spoilage (found at 30% completion as to laborand 15% as to overhead due to internal failure) 400 Cost data for the month:In process beginning:Transferred in 15,020 Special materials 1,900 Direct labor 4,388 Overhead 11,044 Current costs:Transferred in 137,080 Special materials 14,030 Direct labor 46,000 Overhead 113,564 The cost of units transferred to finished goods is?The cost of spoilage charged to revenue is?arrow_forwardFive customers brought in computers to be repaired to a small shop. Estimated repair times (in days) and dates promised are given below. Due dates were set based on available technicians; however, one technician had a medical emergency and will be unavailable for at least two weeks so processing times were adjusted. 1 2 3 Customer job Processing time (days) Due date (days) 3 5 4 -Select- 3 4 -Select- 2 4 6 10 5 5 Use the EDD rule and compute the start time, flow time, lateness, and tardiness for each job. Use minus sign to enter negative lateness values, if any. If your answer is zero, enter "0". 7 Sequence Start Time, days Flow Time, days Lateness, days Tardiness, days -Select- -Select- ✓ -Select-arrow_forward

- Problem 5-11 (Algo) A manager must decide which type of machine to buy, A, B, or C. Machine costs (per individual machine) are as follows: Machine A B C Cost $80,000 $70,000 $40,000 Product forecasts and processing times on the machines are as follows: Annual Product Demand 1 25,000 2 22,000 3 20,000 4 9,000 PROCCESSING TIME PER UNIT (minutes) AS335 4 1 6 Click here for the Excel Data File U2462 Carrow_forwardEmployees Layoffs at the University Medical Center The University Medical Center is medium-sized, 300-bed capacity hospital at Dasmarinas Cavites. The facilities have grown gradually over the years and are now the 2nd largest in the town of Dasmarinas. It is entirely nonunion and has never experienced an employee layoff since its inception. Sister Veronica Cornista, the Chief Executive Officer of the hospital for 8 years presented a rather bleak financial of the BOD. This according to her is the result of the declining occupancy rate which has affected the hospital’s revenues to such an extent that it ran a deficit for the first time last 1998. Such declines have not been unusual for this industry because of increasing competition. So far, the only response to these changes has been tightening of requirements for equipment or supply purchases. The projected deficit for the coming year is around 1,300,000 unless some additional revenues were identified or some additional savings…arrow_forwardEx 5 Fitzsimmons & Fitzsimmons (2008) compare 2 capacity management strategies. Part of their comparison is presented below: Capacity plan: Level Capacity Chase Demand Customer waiting Generally low Moderate High Long run Labour skill level Low Forecasting Short run a) Motivate why the forecasting horizon is longer for Level capacity plans. b) Which assumption is used to reach the conclusion that a level capacity plan has a shorter customer waiting time?arrow_forward

- Charles Lackey operates a bakery in Idaho Falls, Idaho. Because of its excellent product and excellent location, demand has increased by 35% in the last year. On far too many occasions, customers have not been able to purchase the bread of their choice. Because of the size of the store, no new ovens can be added. At a staff meeting, one employee suggested ways to load the ovens differently so that more loaves of bread can be baked at one time. This new process will require that the ovens be loaded by hand, requiring additional manpower. This is the only production change that will be made in order to meet the increased demand. The bakery currently makes 1,500 loaves per month. Employees are paid $88 per hour. In addition to the laborcost, Charles also has a constant utility cost per month of $800 and a per loaf ingredient cost of $0.35 Current multifactor productivity for 640 work hours per month = loaves/dollar (round your response to three decimal places).arrow_forwardCharles Lackey operates a bakery in Idaho Falls, Idaho. Because of its excellent product and excellent location, demand has increased by 25% in the last year. On far too many occasions, customers have not been able to purchase the bread of their choice. Because of this size of the store, no new ovens can be added. At a staff meeting, one employee suggested ways to load the ovens differently so that more loaves of bread can be baked at one time. This new process will requrie that the ovens be, loaded by hand, requiring additional manpower. This is the only production change that will be made in order to meet the increased demand. The bakery currently makes 1,600 loaves per month. Employees are paid $8 per hour. In addition to the labor cost, Charles also has a constant utility cost per month of $700 and a per loaf ingredient cost of $0.50. Current multifactor productivity for 640 work hours per month= .242 loaves/dollar (round your response to three decimal places). After increasing…arrow_forwardTax Prep Advisers, Inc., has forecasted the following staffingrequirements for tax preparation associates over the next12 months. Management would like three alternative staffingplans to be developed. The company currently has 10 associates. No more than 10new hires can be accommodated in any month because oflimited training facilities. No backorders are allowed, andovertime cannot exceed 25 percent of regular-time capacityon any month. There is no cost for unused overtime capac-ity. Regular-time wages are $1,500 per month, and overtimewages are 150 percent of regular-time wages. Undertime ispaid at the same rate as regular time. The hiring cost is $2,500per person, and the layoff cost is $2.000 per person.a. Prepare a staffing plan utilizing a level workforce strategy,minimizing undertime. The plan may call for a one-timeadjustment of the workforce before month 1.b. Using a chase strategy, prepare a plan that is consistent withthe constraint on hiring and minimizes use of overtime.c.…arrow_forward

- Charles Lackey operates a bakery in Idaho Falls, Idaho. Because of its excellent product and excellent location, demand has increased by 55% in the last year. On far too many occasions, customers have not been able to purchase the bread of their choice. Because of the size of the store, no new ovens can be added. At a staff meeting, one employee suggested ways to load the ovens differently so that more loaves of bread can be baked at one time. This new process will require that the ovens be loaded by hand, requiring additional manpower. This is the only production change that will be made in order to meet the increased demand. The bakery currently makes 1,600 loaves per month. Employees are paid $ 8 per hour. In addition to the labor cost, Charles also has a constant utility cost per month of $ 850 and a per loaf ingredient cost of $ 0.35. Part 2 Current multifactor productivity for 640 work hours per month = enter your response here loaves/dollar (round…arrow_forwardCharles Lackey operates a bakery in Idaho Falls, Idaho. Because of its excellent product and excellent location, demand has increased by 45%in the last year. On far too many occasions, customers have not been able to purchase the bread of their choice. Because of the size of the store, no new ovens can be added. At a staff meeting, one employee suggested ways to load the ovens differently so that more loaves of bread can be baked at one time. This new process will require that the ovens be loaded by hand, requiring additional manpower. This is the only production change that will be made in order to meet the increased demand.The bakery currently makes 1,800 loaves per month. Employees are paid $8 per hour. In addition to the labor cost, Charles also has a constant utility cost per month of $650 and a per loaf ingredient cost of $0.40. After increasing the number of work hours to 928 per month,what is the multifactor productivity =? loaves/dollar (round your response to…arrow_forwardCharles Lackey operates a bakery in Idaho Falls, Idaho. Because of its excellent product and excellent location, demand has increased by 45% in the last year. On far too many occasions, customers have not been able to purchase the bread of their choice. Because of the size of the store, no new ovens can be added. At a staff meeting, one employee suggested ways to load the ovens differently so that more loaves of bread can be baked at one time. This new process will require that the ovens be loaded by hand, requiring additional manpower. This is the only production change that will be made in order to meet the increased demand. The bakery currently makes 1,500 loaves per month. Employees are paid $8 per hour. In addition to the labor cost, Charles also has a constant utility cost per month of $550 and a per loaf ingredient cost of $0.40. Current multifactor productivity for 640 work hours per month = 0.239 loaves/dollar (round your response to three decimal places). After increasing the…arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,