Principles of Cost Accounting

17th Edition

ISBN: 9781305087408

Author: Edward J. Vanderbeck, Maria R. Mitchell

Publisher: Cengage Learning

expand_more

expand_more

format_list_bulleted

Concept explainers

Textbook Question

Chapter 4, Problem 2P

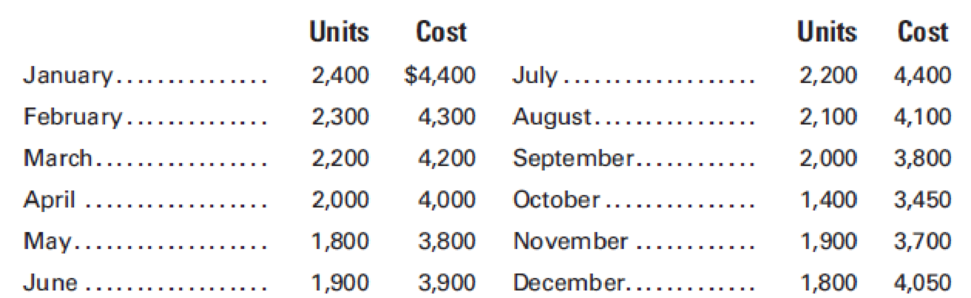

Miller Minerals Co. manufactures a product that requires the use of a considerable amount of natural gas to heat it to a desired temperature. The process requires a constant level of heat, so the furnaces are maintained at a set temperature for 24 hours a day. Although units are not continuously processed, management desires that the variable cost be charged directly to the product and the fixed cost to the factory

Required:

- 1. Separate the variable and fixed elements, using the high-low method.

- 2. Determine the variable cost to be charged to the product for the year. (Hint: First determine the number of annual units produced.)

- 3. Determine the fixed cost to be charged to factory overhead for the year.

Expert Solution & Answer

Want to see the full answer?

Check out a sample textbook solution

Students have asked these similar questions

For each of the transactions above, indicate the amount of the adjusting entry on the elements of the balance sheet and income statement.Note: Enter negative amounts with a minus sign.

Need help with this question solution general accounting

Don't use ai given answer accounting questions

Chapter 4 Solutions

Principles of Cost Accounting

Ch. 4 - What are factory overhead expenses, and what...Ch. 4 - What are three categories of factory overhead...Ch. 4 - What are the distinguishing characteristics of...Ch. 4 - When a products cost is composed of fixed and...Ch. 4 - What effect does a change in volume have on total...Ch. 4 - Distinguish between a step-variable cost and a...Ch. 4 - What is the basic premise underlying the high-low...Ch. 4 - What are the advantages and disadvantages of the...Ch. 4 - Differentiate between an independent variable and...Ch. 4 - Prob. 10Q

Ch. 4 - What is a flexible budget, and how can management...Ch. 4 - How does accounting for factory overhead differ in...Ch. 4 - What is the function and use of each of the two...Ch. 4 - What are two types of departments found in a...Ch. 4 - What are the two most frequently used methods of...Ch. 4 - When using the sequential distribution method of...Ch. 4 - When using the sequential distribution method of...Ch. 4 - Is it possible to close the total factory overhead...Ch. 4 - What are the shortcomings of waiting until the...Ch. 4 - What are the two types of budget data needed to...Ch. 4 - Prob. 21QCh. 4 - What factory operating conditions and data are...Ch. 4 - Prob. 23QCh. 4 - How does activity-based costing differ from...Ch. 4 - What steps must a company take to successfully...Ch. 4 - What is the relationship between activity-based...Ch. 4 - Prob. 27QCh. 4 - Prob. 28QCh. 4 - If the factory overhead control account has a...Ch. 4 - Prob. 30QCh. 4 - Classify each of the following items of factory...Ch. 4 - Ames Automotive Company has accumulated the...Ch. 4 - Prob. 3ECh. 4 - Using the data in E4-2 and spreadsheet software,...Ch. 4 - El Paso Products Company has accumulated the...Ch. 4 - Computing unit costs at different levels of...Ch. 4 - Identifying basis for distribution of service...Ch. 4 - A manufacturing company has two service and two...Ch. 4 - A manufacturing company has two service and two...Ch. 4 - Compute the total job cost for each of the...Ch. 4 - Classify each of the following items of factory...Ch. 4 - Job 25AX required 5,000 for direct materials,...Ch. 4 - Job 19AB required 10,000 for direct materials,...Ch. 4 - Match each of the following cost pools with the...Ch. 4 - The books of Petry Products Co. revealed that the...Ch. 4 - The general ledger of Lawson Lumber Co. contains...Ch. 4 - Nelson Fabrication Inc. had a remaining credit...Ch. 4 - Housley Paints Co. had a remaining debit balance...Ch. 4 - The cost behavior patterns below are lettered A...Ch. 4 - Miller Minerals Co. manufactures a product that...Ch. 4 - Scattergraph method Using the data in P4-2 and a...Ch. 4 - Using the data in P4-2 and Microsoft Excel: 1....Ch. 4 - Listed below are the budgeted factory overhead...Ch. 4 - Menlo Materials is divided into five departments,...Ch. 4 - Distribution of service department costs to...Ch. 4 - Journalizing the distribution of service...Ch. 4 - Channel Products Inc. uses the job order cost...Ch. 4 - Determining job costcalculation of predetermined...Ch. 4 - Focus Fabrication Co. uses ABC. The factory...Ch. 4 - Mansfield Manufacturing Co. uses ABC. The factory...Ch. 4 - Hughes Products Inc. uses a job order cost system....Ch. 4 - Abbey Products Company is studying the results of...Ch. 4 - The following information, taken from the books of...Ch. 4 - Rockford Company has four departmental accounts:...Ch. 4 - Luna Manufacturing Inc. completed Job 2525 on May...Ch. 4 - Phillips Products, Inc. had a remaining credit...Ch. 4 - Nathan Industries had a remaining debit balance of...Ch. 4 - Chrome Solutions Company manufactures special...Ch. 4 - Activity-based Costing

Video Options Ltd....

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, accounting and related others by exploring similar questions and additional content below.Similar questions

- I want to correct answer general accounting questionarrow_forwardKindly help me with accounting questionsarrow_forwardDuo Corporation is evaluating a project with the following cash flows: Year 0 1 2 3 Cash Flow -$ 30,000 12,200 14,900 16,800 4 5 13,900 -10,400 The company uses an interest rate of 8 percent on all of its projects. a. Calculate the MIRR of the project using the discounting approach. Note: Do not round intermediate calculations and enter your answer as a percent rounded to 2 decimal places, e.g., 32.16. b. Calculate the MIRR of the project using the reinvestment approach. Note: Do not round intermediate calculations and enter your answer as a percent rounded to 2 decimal places, e.g., 32.16. c. Calculate the MIRR of the project using the combination approach. Note: Do not round intermediate calculations and enter your answer as a percent rounded to 2 decimal places, e.g., 32.16. a. Discounting approach MIRR b. Reinvestment approach MIRR c. Combination approach MIRR % % %arrow_forward

- Provide correct answer general accounting questionarrow_forwardNeed help with this question solution general accountingarrow_forwardConsider a four-year project with the following information: Initial fixed asset investment = $555,000; straight-line depreciation to zero over the four-year life; zero salvage value; price = $37; variable costs = $25; fixed costs = $230,000; quantity sold = 79,000 units; tax rate = 24 percent. How sensitive is OCF to changes in quantity sold?arrow_forward

- Light emitting diodes (LED) light bulbs have become required in recent years, but do they make financial sense? Suppose a typical 60-watt incandescent light bulb costs $.39 and lasts 1,000 hours. A 15-watt LED, which provides the same light, costs $3.10 and lasts for 12,000 hours. A kilowatt-hour of electricity costs $.115. A kilowatt-hour is 1,000 watts for 1 hour. If you require a return of 11 percent and use a light fixture 500 hours per year, what is the equivalent annual cost of each light bulb? Note: A negative answer should be indicated by a minus sign. Do not round intermediate calculations and round your answers to 2 decimal places, e.g., 32.16.arrow_forwardRecently, Abercrombie & Fitch has been implementing a turnaround strategy since its sales had been falling for the past few years (11% decrease in 2014, 8% in 2015, and just 3% in 2016.) One part of Abercrombie's new strategy has been to abandon its logo-adorned merchandise, replacing it with a subtler look. Abercrombie wrote down $20.6 million of inventory, including logo-adorned merchandise, during the year ending January 30, 2016. Some of this inventory dated back to late 2013. The write-down was net of the amount it would be able to recover selling the inventory at a discount. The write-down is significant; Abercrombie's reported net income after this write-down was $35.6 million. Interestingly, Abercrombie excluded the inventory write-down from its non-GAAP income measures presented to investors; GAAP earnings were also included in the same report. Question: From an investor standpoint, do you think that the effect of the inventory write-down should be considered when…arrow_forwardFinancial accountingarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Principles of Cost AccountingAccountingISBN:9781305087408Author:Edward J. Vanderbeck, Maria R. MitchellPublisher:Cengage Learning

Principles of Cost AccountingAccountingISBN:9781305087408Author:Edward J. Vanderbeck, Maria R. MitchellPublisher:Cengage Learning Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning Managerial AccountingAccountingISBN:9781337912020Author:Carl Warren, Ph.d. Cma William B. TaylerPublisher:South-Western College Pub

Managerial AccountingAccountingISBN:9781337912020Author:Carl Warren, Ph.d. Cma William B. TaylerPublisher:South-Western College Pub Financial And Managerial AccountingAccountingISBN:9781337902663Author:WARREN, Carl S.Publisher:Cengage Learning,

Financial And Managerial AccountingAccountingISBN:9781337902663Author:WARREN, Carl S.Publisher:Cengage Learning, Essentials of Business Analytics (MindTap Course ...StatisticsISBN:9781305627734Author:Jeffrey D. Camm, James J. Cochran, Michael J. Fry, Jeffrey W. Ohlmann, David R. AndersonPublisher:Cengage Learning

Essentials of Business Analytics (MindTap Course ...StatisticsISBN:9781305627734Author:Jeffrey D. Camm, James J. Cochran, Michael J. Fry, Jeffrey W. Ohlmann, David R. AndersonPublisher:Cengage Learning Excel Applications for Accounting PrinciplesAccountingISBN:9781111581565Author:Gaylord N. SmithPublisher:Cengage Learning

Excel Applications for Accounting PrinciplesAccountingISBN:9781111581565Author:Gaylord N. SmithPublisher:Cengage Learning

Principles of Cost Accounting

Accounting

ISBN:9781305087408

Author:Edward J. Vanderbeck, Maria R. Mitchell

Publisher:Cengage Learning

Cornerstones of Cost Management (Cornerstones Ser...

Accounting

ISBN:9781305970663

Author:Don R. Hansen, Maryanne M. Mowen

Publisher:Cengage Learning

Managerial Accounting

Accounting

ISBN:9781337912020

Author:Carl Warren, Ph.d. Cma William B. Tayler

Publisher:South-Western College Pub

Financial And Managerial Accounting

Accounting

ISBN:9781337902663

Author:WARREN, Carl S.

Publisher:Cengage Learning,

Essentials of Business Analytics (MindTap Course ...

Statistics

ISBN:9781305627734

Author:Jeffrey D. Camm, James J. Cochran, Michael J. Fry, Jeffrey W. Ohlmann, David R. Anderson

Publisher:Cengage Learning

Excel Applications for Accounting Principles

Accounting

ISBN:9781111581565

Author:Gaylord N. Smith

Publisher:Cengage Learning

Cost Accounting - Definition, Purpose, Types, How it Works?; Author: WallStreetMojo;https://www.youtube.com/watch?v=AwrwUf8vYEY;License: Standard YouTube License, CC-BY