OPERATIONS MANAGEMENT CUSTOM ACCESS

11th Edition

ISBN: 9780135622438

Author: KRAJEWSKI

Publisher: PEARSON EDUCATION (COLLEGE)

expand_more

expand_more

format_list_bulleted

Concept explainers

Textbook Question

Chapter 11, Problem 25P

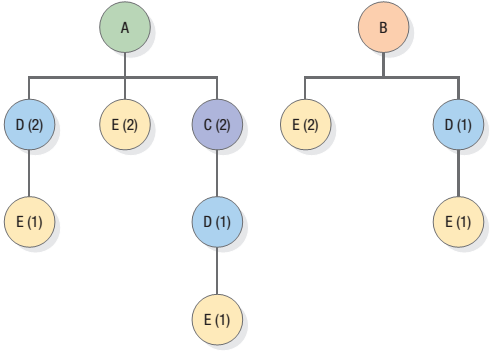

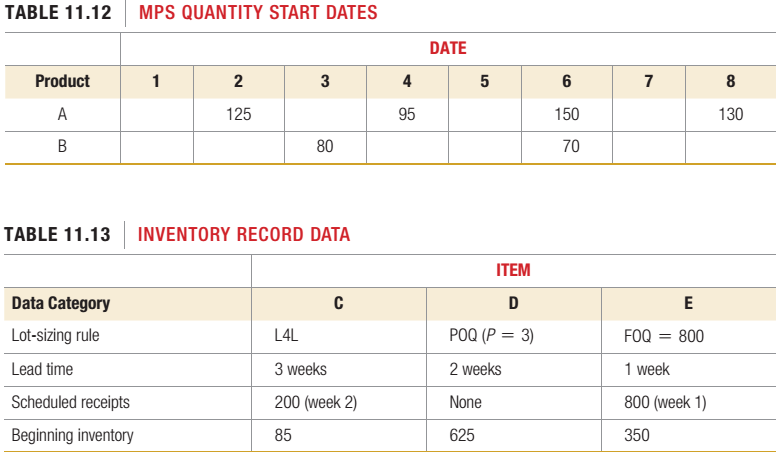

Figure 11.44 shows the BOMs for two products, A and B. Table 11.12 shows the MPS quantity start date for each one. Table 11.13 contains data from inventory records for items C, D, and E. There are no safety stock requirements for any of the items.

- Determine the material requirements plan for items C, D, and E for the next 8 weeks.

- What specific managerial actions are required in week 1?

- Suppose that a very important customer places an emergency order for a quantity of product A. TO satisfy this order, a new MPS of 200 units of product A is now required in week 5. Determine the changes to the material requirements plan if this order is accepted and note any problems that you detect.

Expert Solution & Answer

Want to see the full answer?

Check out a sample textbook solution

Students have asked these similar questions

Complete the following table. Lead time for the part is 2 weeks, and the order quantity is 50. What action should be taken?

The table given below shows a partially completed MPS record for product A. What is the

remaining ATP inventory (discrete) for week 7 after the company receives a 20 units of customer

order for week 6?

Order policy: 60 units

Lead time: 1 week

Item: A

Quantity on hand: 30

Week

3

30

7.

34

11

4.

Forecast requirements

Customer orders (booked)

Projected on-hand inventory

MPS quantity

MPS start

ATP inventory

22

24

18

27

36

28

26

12

24

O a 59

Ob. 29

OcO

Od. 49

Oe. 39

Figure shows the BOMs for two products, A and B. Table 1 shows the MPS quantity start date for each one. Table 2 contains data from inventory records for items C, D, and E. There are no safety stock requirements for any of the items.a. Determine the material requirements plan for items C, D, and E for the next 8 weeks.b. What specific managerial actions are required in week 1?c. Suppose that a very important customer places an emergency order for a quantity of product A. To satisfy this order, a new MPS of 200 units of product A is now required in week 5. Determine the changes to the material requirements plan if this order is accepted and note any problems that you detect.

MPS Quantity Start Dates

Date

Product

1

2

3

4

5

6

7

8

A

125

95

150

130

B

80

70

Inventory Record Data

Item

Data Category

C

D

E

Lot-sizing rule

L4L

POQ 1P = 32

FOQ = 800

Lead time

3 weeks

2 weeks

1 weeks

Scheduled receipts

200 (week 2)

None

800 (week 1)

Beginning…

Chapter 11 Solutions

OPERATIONS MANAGEMENT CUSTOM ACCESS

Ch. 11 - Consider the master flight schedule of a major...Ch. 11 - For an organization of your choice, such as where...Ch. 11 - Consider a service provider that is in the...Ch. 11 - Complete the MPS record in Figure 11.29 for a...Ch. 11 - Complete the MPS record in Figure 11.30 for a...Ch. 11 - Prob. 3PCh. 11 - Figure 11.31 shows a partially completed MPS...Ch. 11 - Tabard Industries forecasted the following demand...Ch. 11 - Figure 11.32 shows a partially completed MPS...Ch. 11 - The forecasted requirements for an electric hand...

Ch. 11 - A forecast of 240 units in January, 320 units in...Ch. 11 - An end items demand forecasts for the next 6 weeks...Ch. 11 - An end items demand forecasts for the next 10...Ch. 11 - Consider the bill of materials (BOM) in Figure...Ch. 11 - Product A is made from components B, C, and D....Ch. 11 - What is the lead time (in weeks) to respond to a...Ch. 11 - Product A is made from components B and C. Item B,...Ch. 11 - Refer to Figure 11.23 and Solved Problem 1. If...Ch. 11 - The partially completed inventory record for the...Ch. 11 - The partially completed inventory record for the...Ch. 11 - The partially completed inventory record for the...Ch. 11 - Figure 11.38 shows a partially completed inventory...Ch. 11 - A partially completed inventory record for the...Ch. 11 - The BOM for product A is shown in Figure 11.40,...Ch. 11 - The BOMs for products A & B and data from the...Ch. 11 - Figure 11.42 illustrates the BOM for product A....Ch. 11 - The following information is available for three...Ch. 11 - Figure 11.44 shows the BOMs for two products, A...Ch. 11 - The BOM for product A is shown in Figure 11.45....Ch. 11 - Refer to Solved Problem 1 (Figure 11.23) for the...Ch. 11 - The bill of materials and the data from the...Ch. 11 - The bill of materials and the data from the...Ch. 11 - The McDuff Credit Union advertises their ability...Ch. 11 - Suppose that the POQ for item B is changed from 3...Ch. 11 - As the on-hand inventory for item C increases from...Ch. 11 - As the fixed order quantity (FOQ) for item D...Ch. 11 - As the lead time for item C changes, what happens...

Additional Business Textbook Solutions

Find more solutions based on key concepts

What is precedent, and how does it affect common law?

Business in Action (8th Edition)

Feeding America Each year, the Feeding America network helps provide food to more than 46 million people facing...

Operations and Supply Chain Management 9th edition

There is a huge demand in the United States and elsewhere for affordable women’s clothing. Low-cost clothing re...

Loose-leaf for Operations Management (The Mcgraw-hill Series in Operations and Decision Sciences)

Many companies including Company OM tried to implement dynamic pricing in their ticketing system. The dynamic p...

Principles of Operations Management: Sustainability and Supply Chain Management (10th Edition)

2. In what circumstances might a market-pull approach or a technology-push approach to new-product design be th...

OPERATIONS MANAGEMENT IN THE SUPPLY CHAIN: DECISIONS & CASES (Mcgraw-hill Series Operations and Decision Sciences)

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, operations-management and related others by exploring similar questions and additional content below.Similar questions

- Assume you are the manager of a shop that assembles power tools. You have just received an order for 55 chain saws, which are to be shipped at the start of week 8. Pertinent information on the saws follows: Item Lead Time (weeks) On Hand Saw A B C D E F 2 1 2 2 1 1 2 Gross requirements Scheduled receipts Projected on hand Net requirements Planned order receipt Planned order release Ĉ E(3) & E(2) LT = 1 week Lot size: Lot-for-Lot 15 10 5 65 20 10 30 Skip Extension Tip: Double click to open in new tab Show Transcribed Text Develop the material requirements plan for component E using lot-for-lot ordering for all items. (Leave no cells blank - be certain to enter "0" wherever required.) Components A(2), B(1), C(4) E(3), D(1) D (2), F(3) E(2), D (2) Beg. Inv. 1 2 3 190 5 210 6arrow_forwardFigure shows a partially completed MPS record for 2 inch pneumatic control valves. Suppose that you receive the following orders at right for the valves (shown in the order of their arrival). As they arrive, you must decide whether to accept or reject them. Which orders would you accept for shipment?Order Amount (Units) Week Requested1 15 22 30 53 25 34 75 7arrow_forwardHeather Adams, production manager for a Colorado exercise equipment manufacturer, needs to schedule an order for 50 UltimaSteppers, which are to be shipped in week 8. Subscripts indicate quantity required for each parent. Assume lot-for-lot ordering. b. Choose correct time phased-structures c. Develop a net material requirements plan for F (enter your responses as whole numbers).arrow_forward

- Shown below is a partially completed MPS record for hand drills. a. Develop the MPS record for the hand drills. (Enter your responses as integers. A response of "0" is equivalent to being not applicable.) Item: Hand drills Quantity on Hand: 30 Forecast Customer orders (booked) Projected on-hand inventory MPS quantity MPS start 1 15 20 N 40 25 3 15 15 Week Available-to- promise (ATP) inventory b. A distributor of the hand drills places an order for 15 units. What is the appropriate shipping date for the entire order? The order should ship on week (Enter your response as an integer.) 4 20 20 Order Policy: 60 units Lead Time: 1 week 5 55 0 6 35 0arrow_forwardHeather Adams, production manager for a Colorado exercise equipment manufacturer, needs to schedule an order for 50 UltimaSteppers, which are to be shipped in week 9. Subscripts indicate quantity required for each parent. Assumelot-for-lot ordering. c) Develop a net material requirements plan for F (enter your responses as whole numbers). Week Lead Time Item 2 3 4 5 6 7 8 9 (weeks) F Gross req Insert answer insert answer 2 On hand insert answer insert answer Net req insert answer insert answer Order receipt insert answer insert answer Order release insert answer insert answerarrow_forwardA factory has just received an order for 100 units of an end item, which are to be shipped at the start of week 8. Relevant information of the end item and the components is as follows. Item Lead Time (weeks) On Hand Inventory Scheduled receipts Order Policy Direct Components End item 2 30 lot for lot A(4), B(3), C(2) A 3 20 54 at week 3 lot for lot D(2) B 2 10 68 at week 4 lot for lot D(5) C 1 100 multiple of 60 D 1 20 min. of 500 Develop the material requirements plan (please print out an empty MRP table to work with), and determine what the "projected available balance" is for component D at week 8. Note:- Do not provide handwritten solution. Maintain accuracy and quality in your answer. Take care of plagiarism. Answer completely. You will get up vote for sure.arrow_forward

- Shown below is a partially completed MPS record for ball bearings. Part 2 a. Develop the MPS for ball bearings. (Enter your responses as integers. A response of "0" is equivalent to being not applicable.) Item: Ball bearings Order Policy: 500 units Lead Time: 1 week Quantity on Hand: 400 Week 1 2 3 4 5 6 7 8 9 10 Forecast 550 350 350 450 250 300 250 350 400 350 Customer orders (booked) 300 350 250 300 150 150 150 150 100 50 Projected on-hand inventory enter your response here enter your response here enter your response here enter your response here enter your response here enter your response here enter your response here enter your response here enter your response here enter your response here MPS quantity 500 enter your response here enter your response here enter your response here enter your…arrow_forwarda) Given the product structure and master production scheduleshown in Figure 14.12, develop a gross requirements plan forall items.b) G iven the product structure, master production schedule, andinven tory status shown in Figure 14.12, develop a net requirementsplan (planned order release) for all items.arrow_forwardSolution for Material Requirement Planningarrow_forward

- What is the net requirement using a Material Requirements Planning program if the gross requirement is 1,250 and the inventory on hand is 50?arrow_forwardRefer to this product tree If 17 Ps are needed, and no on-hand inventory exists for any items, how many Cs will be needed?arrow_forwardYou have developed the following simple product structure of items needed for your gift bag for a rush party for prospective pledges in your organization. You forecast 200 attendees. Assume that there is no inventory on ha nd of any of the items. Explode the bill of material. (Subscripts indicate the number of units required.)arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.

Inventory Management | Concepts, Examples and Solved Problems; Author: Dr. Bharatendra Rai;https://www.youtube.com/watch?v=2n9NLZTIlz8;License: Standard YouTube License, CC-BY